SOLIDWORKS Simulation 2026 introduces a powerful suite of updates across Structural, Plastics, and Flow Simulation. From smarter load definitions and refined diagnostics to enhanced thermal analysis and molding predictions, these improvements give engineers greater control, faster feedback, and more realistic results.

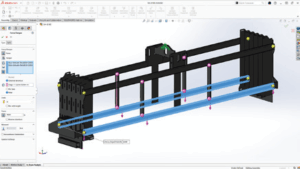

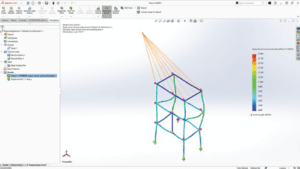

1. Force Options for Beams

Engineers can now define beam forces as Per Item or Total, providing more flexibility and realism when applying structural loads.

Benefit: Achieve precise control to accurately represent real-world loading conditions.

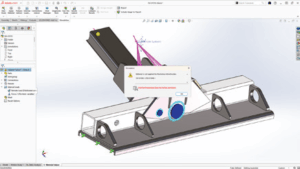

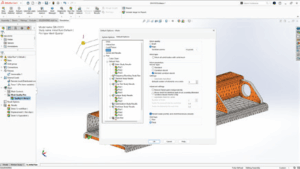

2. Validity Check Improvements

Simulation setup is faster and more reliable, with clearer alerts for missing materials, invalid mesh controls, or incomplete fixtures. Streamlined messages and one-click deselection make troubleshooting easier.

Benefit: Resolve setup issues quickly and ensure higher simulation accuracy.

3. Pin Connector Forces in Random Vibration

Random vibration studies now include detailed force breakdowns, shear, axial, bending, and torque, at pin connectors.

Benefit: Capture realistic joint behavior for improved design confidence.

4. Angular Displacement Plot Options

Angular rotation can now be displayed in degrees or radians, aligning results with engineering standards or project requirements.

Benefit: Gain flexibility in interpreting and reporting displacement data.

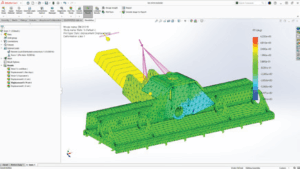

5. Shell Improvements

Shell workflows are enhanced with new global defaults for thick or thin shells and the ability to apply distributed remote loads or mass along shell edges.

Benefit: Reduce setup time while improving accuracy in complex shell models.

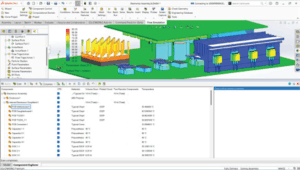

6. Component Explorer Enhancements

Thermal analysis is more intuitive with new temperature and surface source columns in the Component Explorer, allowing quick identification of overheating areas or imbalanced heat sources.

Benefit: Perform faster, clearer thermal assessments at a glance.

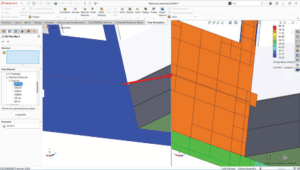

7. Fill Thin Slot for Thermal Modeling

Automatically fill thin slots with defined materials to better simulate heat transfer in compact or bonded assemblies.

Benefit: Produce more realistic and reliable thermal simulation results.

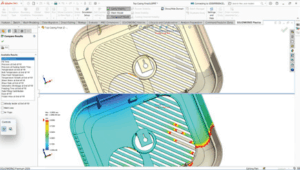

8. Edge-Based Air Vent Definition

Define Air Vent boundary conditions directly on model edges for mold simulations, applicable to both cavity and runner domains.

Benefit: Improve venting accuracy and mold flow predictions.

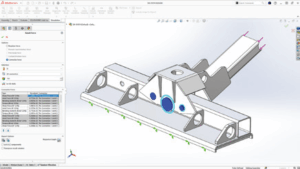

9. Remote Mass in Response Spectrum

Assign remote masses to represent components not meshed in the study, ensuring their influence is accurately considered.

Benefit: Streamline simulation setup while maintaining result precision.

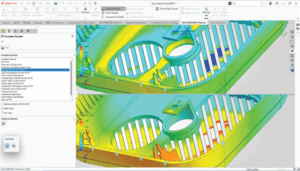

10. Post-Processing Enhancements in Plastics

A new Unfilled Volume plot complements short-shot predictions, allowing quick identification of incomplete injection zones.

Benefit: Detect and address molding issues faster for improved manufacturability.

It’s Now your Turn to Harness the Full Power of SOLIDWORKS 2026

From beam loading flexibility to smarter diagnostics and enhanced plastics visualization, SOLIDWORKS Simulation 2026 advances simulation accuracy and efficiency. These top 10 enhancements empower engineers to handle more complex scenarios, troubleshoot faster, and deliver designs with greater confidence.

At Solidxperts, our Simulation Specialists help you unlock the full potential of SOLIDWORKS Simulation, from setup and validation to advanced analysis and automation. Whether upgrading to 2026 or streamlining complex studies, our experts will help you.