Marketing Hype or True Industry Revolution?

Since the dawn of engineering, predicting how a part behaves under load has always been a challenge for designers. Today, we have advanced simulation methods built on decades of research and development. Yet, simulating a 3D-printed part remains complex.

Most modeling software still doesn’t account for the anisotropic properties of 3D printing, especially when it comes to continuous fiber reinforcements like those offered by Markforged.

Additive manufacturing, with its fast iteration cycles, does allow multiple versions of a part to be printed and tested in order to converge on an acceptable solution. But this approach has its limits: some problems are long and costly to solve, both in time and in material.

This is where Eiger comes in. Markforged’s software integrates a simulation and optimization module designed to bring the printed part’s real-world performance closer to the design goals, right from the first print.

So, what is this software really worth? Just marketing fluff, or a genuine game changer for the industry? Let’s dig deeper.

1. Access to Simulation

Simulation is only available with the Advanced Digital Forge plan. Once activated, you simply import a part into Eiger, define the printing parameters, and head to the SIM tab.

Want to learn more about the Advanced Digital Forge plan, get a personalized demo, or even test your own part optimizations? Contact us, we’ll be happy to help.

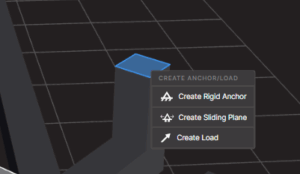

You’ll then see a 3D view of the part along with a panel for setting up the simulation conditions:

-

applied loads,

-

fixed surfaces or regions,

-

desired safety factor,

-

maximum allowable deflection.

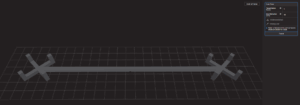

For this article, we used the example of a beam subjected to a bending force.

2. Defining and Running a Load Case

Each scenario is defined by selecting the relevant surfaces (for example, sliding planes or fixed supports) and applying a given force.

In our test, a force of 7.7 N was applied.

The simulation runs in the cloud, which eliminates the need to dedicate local resources or a separate server. While the calculation is running, you can continue working and return once the results are ready.

3. Simulation Results

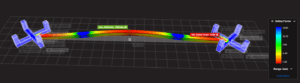

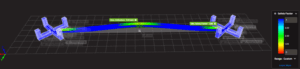

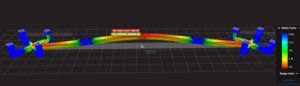

The module then generates a color-coded 3D rendering highlighting:

-

the safety factor (stress vs. strength),

-

the maximum deflection.

Example:

-

With a 7.7 N load, the safety factor was 0.99 → failure expected.

-

The maximum deflection measured was 7.93 mm.

-

With a 7 N load, the safety factor rose above 1, meaning the beam could withstand the force but would fail around 7.7 N.

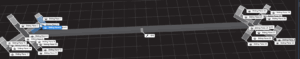

4. Limits and Interpretation

Like any simulation software, Eiger is based on an idealized model of the part, with theoretical load and constraint conditions. This means that results may vary depending on how the case is defined.

For example, for the same beam subjected to the same load, choosing between sliding planes or fixed supports can lead to two equally realistic simulations. The overall stress zones remain similar, but the location of the maximum stress changes.

This underlines a key rule: you can’t just take the raw results at face value, you need to analyze and interpret them carefully. The tool’s true value lies not only in calculation accuracy but also in the engineer’s ability to understand what the results mean for the design.

Fortunately, thanks to the color visualization and customizable table, critical areas are easy to spot. In our test, three clear stress concentration zones were identified, allowing the designer to anticipate issues and reinforce the part at the design stage.

From Theory to Practice: Eiger as an Innovation Accelerator

Eiger is more than just a slicer for Markforged printers, it’s a design tool. It enables simulation of multiple designs, performance forecasting, and significant time savings before the first physical test.

In our next article, we’ll look at strategies for optimizing a part after simulation and compare the virtual results with real-world testing to validate failure thresholds.

Want to go further? Reach out to our team to explore the Advanced Digital Forge plan, schedule a demo, or benefit from a personalized analysis of your parts.