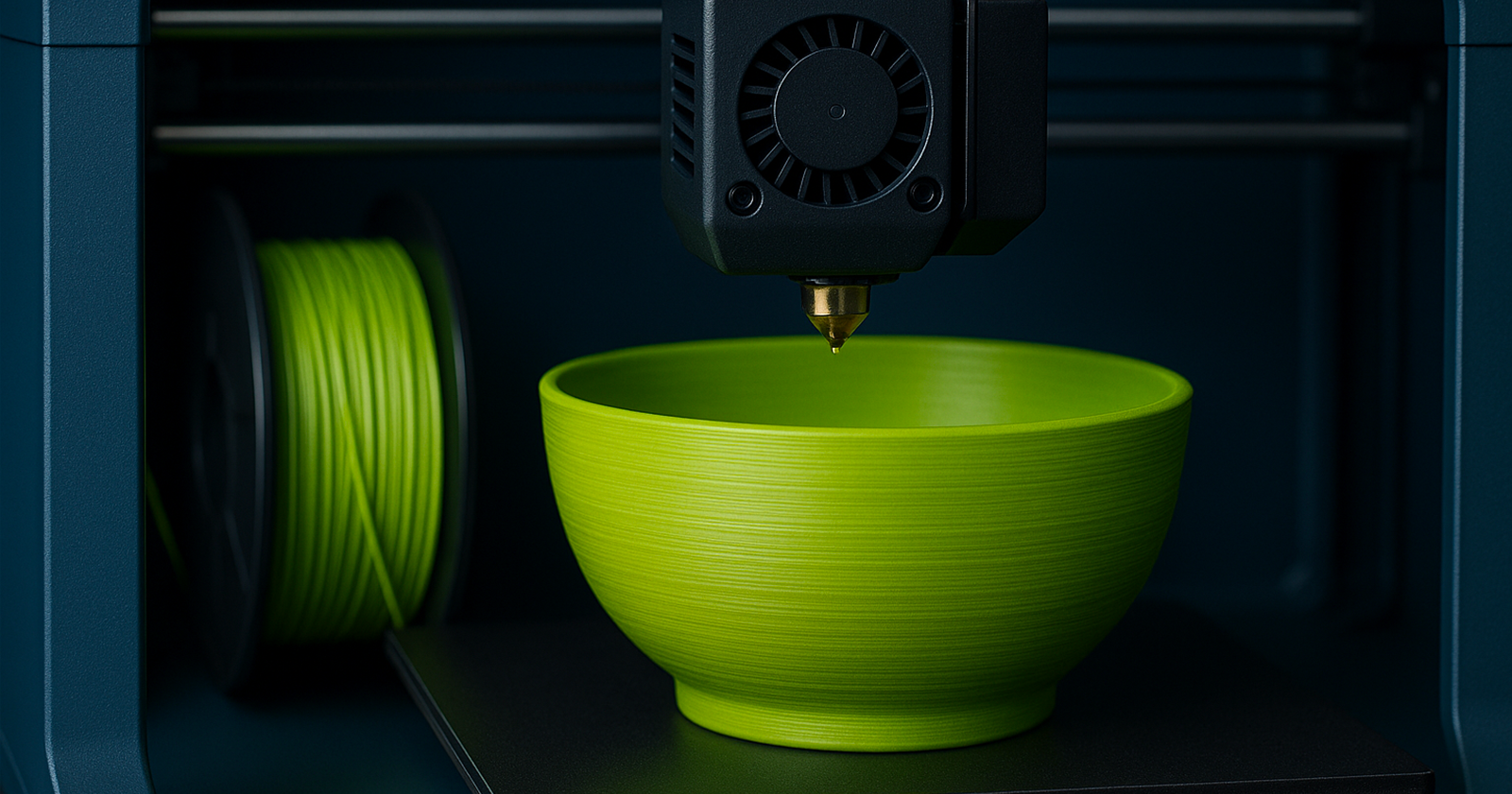

3D printing has already transformed industries like aerospace, automotive, and healthcare with rapid prototyping and on-demand production. But in the food and beverage industry, adoption has been much slower. Why? One key reason: the lack of certified food safe 3D printer filament.

That’s now changing. With new compliant materials available, manufacturers can finally use additive manufacturing to create safe, durable, and customizable parts for production environments without compromising food safety standards.

Why Food Safe 3D Printing Materials Are Critical

For food and beverage manufacturers, the real challenge isn’t just speed. It’s staying compliant while keeping production moving. Every component used on the line, from conveyor guides to packaging tools, is subject to strict hygiene standards. A non-certified material can introduce risks like contamination, regulatory fines, or costly recalls.

This is where food safe 3D printer filament becomes a game-changer. By using certified materials, teams can create replacement parts and custom tooling quickly without sacrificing compliance. Instead of waiting weeks for machined plastics or stainless steel components, manufacturers gain the flexibility of in-house printing while still meeting food-contact regulations. The result is less downtime, lower costs, and peace of mind that safety standards aren’t being compromised.

Where Food Safe 3D Filament Fits in Manufacturing

To understand how food safe 3D printer filament fits into the manufacturing process, it’s helpful to use the industry-standard “zone” concept:

Food safe 3D printer filament isn’t just about meeting regulations. It’s about keeping operations running smoothly across the entire production workflow. The biggest opportunities show up in three critical areas:

-

Upstream operations: Custom funnels, chutes, and forming tools help direct ingredients without risk of contamination.

-

In-line equipment: Conveyor guides, pushers, and diverters can be printed in-house to reduce downtime and adapt quickly to new product runs.

-

Downstream packaging: Non-marring brackets, clamps, and supports ensure products are packaged safely while minimizing damage and waste.

By viewing food safe filament through the lens of workflow impact, manufacturers can pinpoint where certified materials will have the greatest effect, reducing delays, cutting costs, and ensuring compliance at every stage of production.

Another way to think about it comes from Markforged’s blog on food safe 3D printing. They highlight that it isn’t just about where the part is used, but also about how it performs under factory conditions, resisting heat, moisture, and repeated sanitation cycles. In other words, compliance is only the first step; durability and cleanability are just as important when evaluating materials for food-contact environments.

Food safe filament is most transformative in Zones 1 and 2. In these areas, compliance with certifications like NSF/ANSI Standard 51 and FDA CFR Title 21 is often a requirement, not a recommendation.

Buyer’s Guide: What to Look for in a Certified Food Safe Filament

Choosing the right material isn’t just about grabbing the first “FDA approved” filament you find. There are key considerations every manufacturer should keep in mind:

-

Check the actual certification: Not all “food safe” claims are equal. Look for NSF/ANSI 51, FDA CFR Title 21, or EC 1935/2004 compliance.

-

Understand limitations: Some filaments are certified for certain food types only (for example, excluding alcohol contact).

-

Consider surface finish: Even certified materials can fail audits if the printed part has a rough surface that traps contaminants.

-

Think long-term durability: The filament should withstand repeated washdowns, high humidity, and daily wear.

-

Match material to your workflow: Does your team have post-processing capabilities like sanding or vapor smoothing? If not, pick a filament that prints with naturally smoother finishes.

A smart buying decision combines compliance with practicality. The “best” food safe filament is one that not only meets regulations but also fits seamlessly into your team’s printing, cleaning, and production processes.

How Manufacturers Apply Food Safe 3D Printer Filament

With the right material, food manufacturers can confidently print parts such as:

-

Conveyor pushers, diverters, and guides

-

Funnels and chutes for packaged goods

-

Robotic end-of-arm tooling

-

Non-marring clamps, brackets, and supports

The value lies in customization. Teams can design parts for unique product lines, adjust them on the fly, and replace them in-house without long lead times.

Choosing and Comparing Food Safe 3D Printing Materials

|

Material |

Food-Safe Certified? |

Pros |

Cons |

|

PLA |

Sometimes |

Easy to print, biodegradable |

Weak and heat-sensitive |

|

PETG |

Often (FDA grades) |

Good chemical resistance, stronger than PLA |

Needs post-processing |

|

Standard Nylon |

Rarely |

Strong and durable |

Usually not certified |

|

Nylon White FS |

Yes |

Certified, smooth, durable, industrial-grade |

Not approved for alcohol contact |

Source: Adapted from Markforged’s blog on food safe 3D printer filament

Among these, Nylon White FS stands out as one of the only industrial-grade certified food safe filaments suitable for factory conditions.

Best Practices for Food-Ready 3D Printed Parts

To make sure 3D printed parts are truly food ready, manufacturers need to go beyond just choosing a certified food safe 3D printer filament. Design plays a major role in compliance: parts should feature smooth, sloped surfaces that are easy to clean, while avoiding tight crevices where food particles can collect. Post-processing steps such as sanding or vapor smoothing further reduce surface roughness and improve cleanability. It’s also best practice to dedicate specific printers, nozzles, and build surfaces exclusively for food-contact parts to prevent cross-contamination. Finally, every part must be integrated into validated cleaning and sanitation workflows, ensuring consistent performance in demanding food and beverage environments.

Conclusion: The Strategic Advantage of Food Safe 3D Printing

Food and beverage manufacturers have always faced a difficult balance: strict compliance on one hand, and the need for speed and flexibility on the other. Traditional materials like stainless steel or machined plastics ensured safety, but they slowed innovation and raised costs.

Certified food safe 3D printer filament offers a way forward. It allows teams to reduce downtime with rapid part replacement, keep costs under control by printing in-house, and adapt quickly to new product launches without compromising hygiene.

More importantly, it shifts additive manufacturing from being a prototyping tool to becoming a trusted part of regulated production environments. This means greater agility, faster problem-solving, and the confidence that every printed part aligns with food-contact safety standards.

In short, food safe filament is more than just a material. It’s a competitive edge for manufacturers ready to modernize their operations and lead the future of food production.

Ready to see how certified food safe 3D printing materials could transform your production line? Start exploring your options today by contacting our experts.