In the dynamic engineering world, where rapid iteration and efficient production are paramount, new technologies that accelerate design and manufacturing processes hold immense value. Enter Hyper FFF (Fused Filament Fabrication), a cutting-edge way to 3D print developed by Raise3D. Hyper FFF is a groundbreaking 3D printing system engineered for unparalleled efficiency and performance, offering engineering professionals new advantages in prototyping and small-batch production.

Unleashing Speed and Quality:

At the core of Rasie3D’s Hyper FFF lies its ability to achieve unparalleled print speeds, boasting 100% quality and 300% productivity on its website, while maintaining exceptional part quality. By leveraging advanced hardware, sophisticated feedback loops, specialized filaments, and an active vibration cancellation algorithm, Hyper FFF enables engineers to push the boundaries of speed and efficiency in additive manufacturing. With Hyper FFF, design iterations can be completed in record time, leading to faster product development cycles and increased engineering productivity.

Accelerating Design Iterations for Engineers:

For engineers, design iterations are a critical aspect of the development process. Hyper FFF’s remarkable speed allows engineers to rapidly iterate and refine their designs, facilitating quicker testing, validation, and optimization. The accelerated design process empowers engineers to explore multiple design options, evaluate their performance, and make informed decisions faster than ever before. By shortening the design cycle, designers gain a competitive edge, allowing them to bring innovative products to market more quickly and stay ahead of their competitors.

Reduced Print Time for Engineering Applications:

Hyper FFF’s high-speed capabilities significantly reduce print times for engineering applications. Complex prototypes and small-batch production runs that previously required hours or even days to print can now be produced in substantially less time. This accelerated production process enables engineers to meet tight project deadlines, ensuring timely delivery and increased client satisfaction. With Hyper FFF, engineers can optimize their workflows, enhance productivity, and drive innovation forward.

Enhanced Success Rate and Quality Control:

Hyper FFF technology integrates advanced features, like its active vibration cancellation algorithm and optimized filaments, to improve the rate of successful prints and ensure consistent quality in engineering applications. By mitigating vibrations and minimizing printing failures, Hyper FFF delivers reliable results and reduces material waste. Engineers can achieve a higher percentage of successful prints, leading to improved productivity and cost-effectiveness. Hyper FFF empowers engineers with the confidence that their parts will meet the stringent quality standards required in demanding engineering applications.

Shortened Lead Time for Engineering Parts:

Minimizing lead times is crucial in engineering to maintain project schedules and meet client demands. Hyper FFF’s exceptional speed and quality both directly contribute to shortened lead times for individual or even small-batch printed parts. By harnessing the power of Hyper FFF, engineers can manufacture components faster, accelerating the overall production process. This agility ensures timely project completion, minimizing delays, and improving customer satisfaction. With Hyper FFF, engineering firms gain a competitive advantage by delivering high-quality parts in less time.

Embracing In-House Supply for Engineering Applications:

Hyper FFF’s capabilities make it an ideal solution for in-house supply production in the engineering industry. By leveraging Hyper FFF technology, engineering firms can reduce reliance on external suppliers, streamline their supply chains, and gain greater control over production timelines. With the ability to produce parts on demand, engineers can optimize inventory management, reduce costs, and respond swiftly to changing project requirements. Hyper FFF enables engineering professionals to drive innovation and improve the efficiency of their in-house production processes.

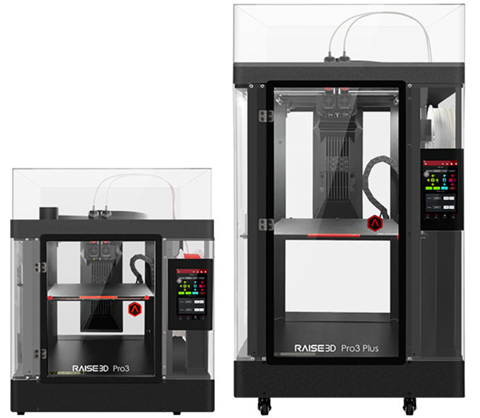

Currently, Hyper FFF technology is primarily available for the Pro3 Series printers. The Pro3 Series printers are specifically engineered to leverage the full potential of Hyper FFF, providing exceptional speed and uncompromising quality. Learn more about the Pro3 series on our product page here. Hyper FFF technology is a game-changer for engineers involved in prototyping and small-batch production. By offering unparalleled speed, uncompromising quality, and increased efficiency, Hyper FFF empowers engineering professionals to accelerate design iterations, reduce lead times, and enhance overall productivity.