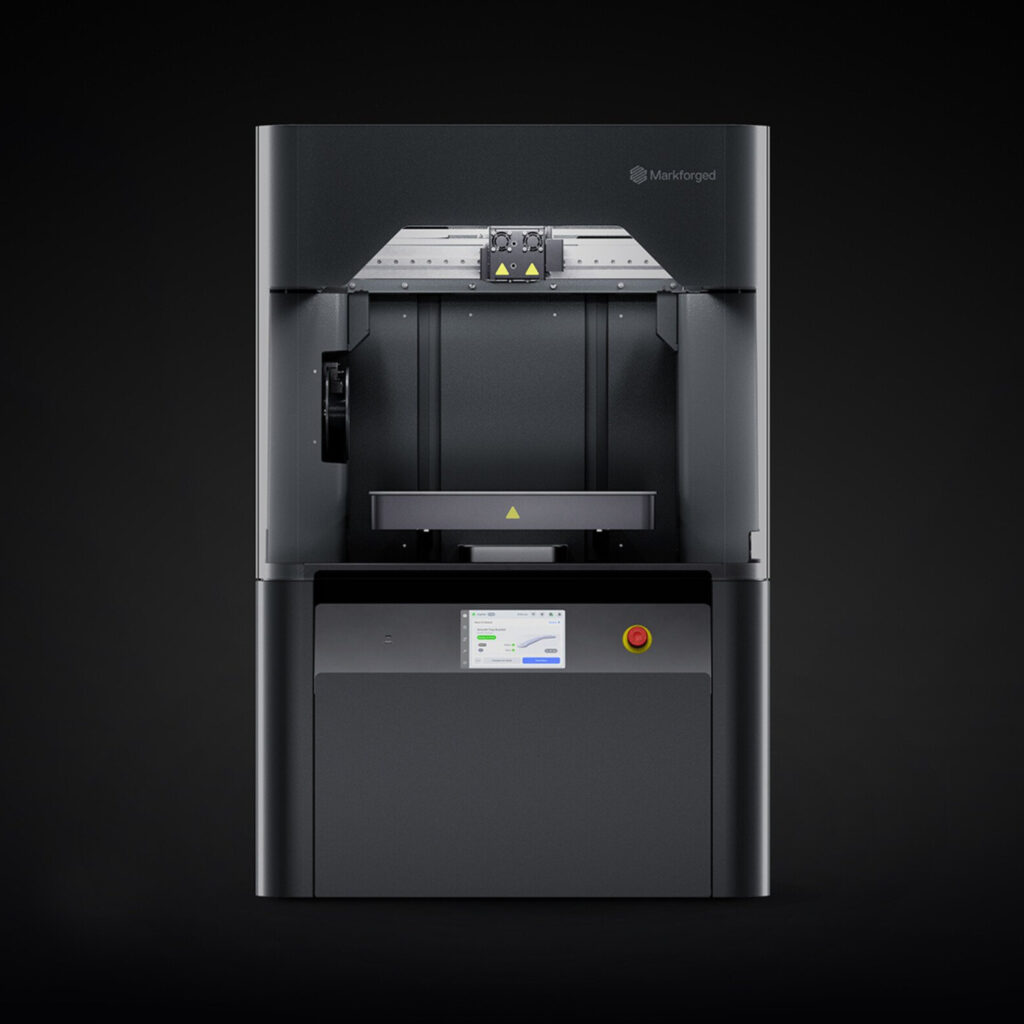

The Markforged FX10 is a next-generation industrial 3D printer that seamlessly integrates composite and metal printing capabilities. Designed for versatility and efficiency, it offers a modular architecture with advanced automation, delivering strong, accurate parts suitable for various industrial applications.

Operate with ease via a 7-inch touchscreen and a seamless Eiger software interface. The FX10’s upgraded material bay stores up to four spools with automatic changeover, and is ready to support both composite and metal printing workflows. Its scalable design ensures adaptability for future manufacturing needs.

Technical Specifications

Engineered to meet the demands of modern industrial production, the Markforged FX10 excels at manufacturing robust and reliable parts for functional prototyping, tooling, and end-use applications. It serves critical roles across sectors such as aerospace, automotive, production engineering, and other manufacturing environments where precision, repeatability, and mechanical performance are essential.

With its unique ability to print both continuous fiber-reinforced composites and industrial-grade metals, the FX10 significantly reduces manufacturing lead times while offering unmatched flexibility for developing custom solutions.

The FX10 also stands out as the only printer in the Markforged portfolio capable of producing food-safe certified parts, thanks to its compatibility with Nylon White FS. This makes it an ideal choice for regulated environments such as the food processing, pharmaceutical, or packaging industries, where material traceability and compliance with hygiene standards are critical.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: