That’s right—it’s that time of year again! 3DEXPERIENCE World 2025 is coming up fast and the Solidxperts team is gearing up to head to Houston, Texas for yet another jammed-packed convention schedule of industry learning, networking, and discovery.

📅 February 23-26th

📍 George R. Brown Convention Center – Houston, Texas (USA)

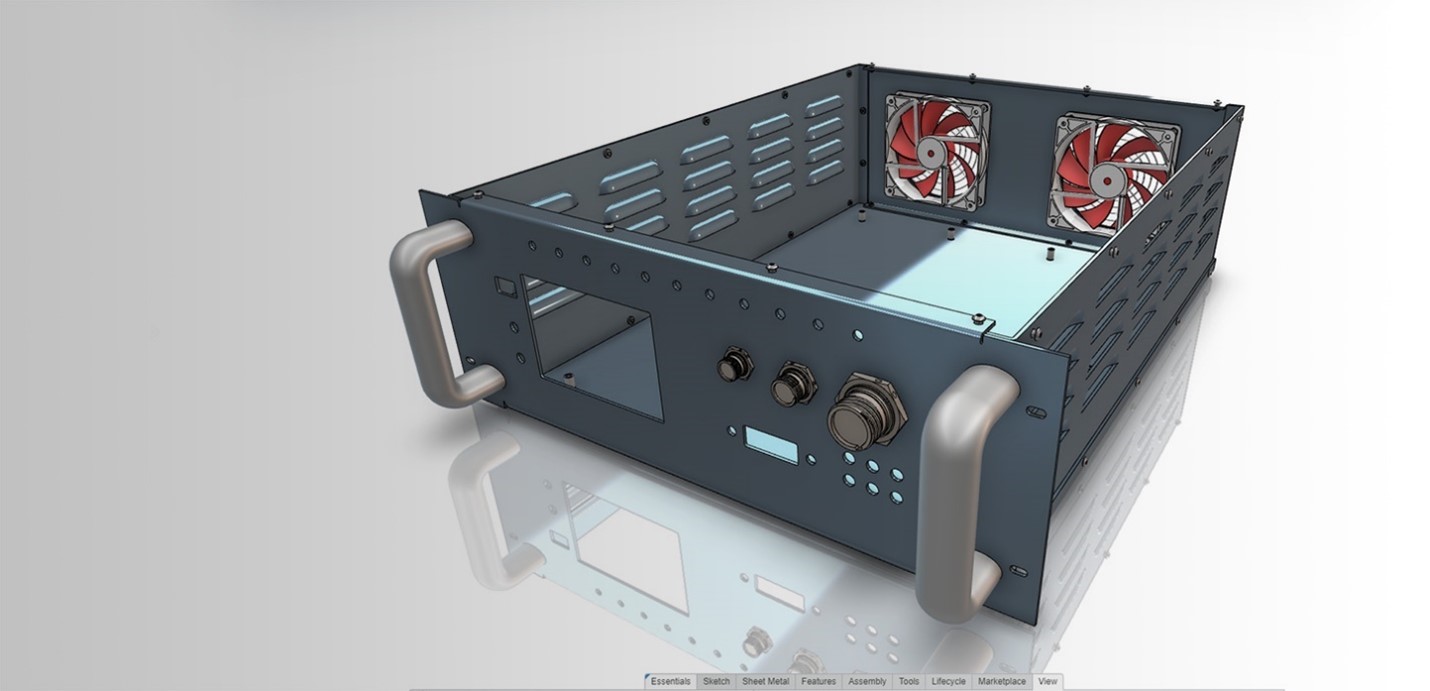

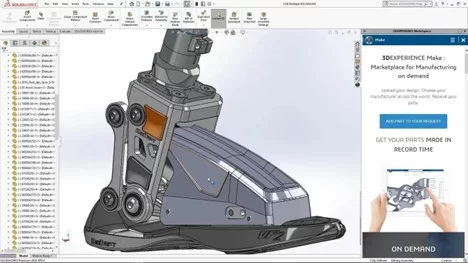

Every year 3DEXPERIENCE World stands as the CAD industry’s premier annual event, highlighting cutting-edge technology, thought leadership, and the latest collaborative tools that fuel our innovation. It offers insightful sessions, hands-on workshops, and countless opportunities to explore industry trends. From advanced design strategies to game-changing SOLIDWORKS tips, this convention has something for everyone.

First Things First: Why Attend?

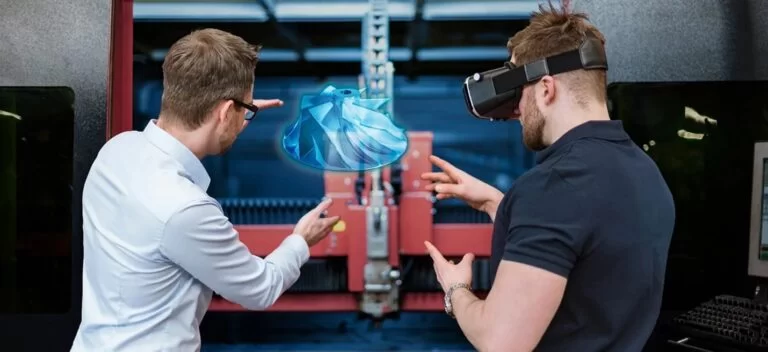

3DEXPERIENCE World 2025 is more than just an event—it’s an opportunity to immerse yourself in the latest advancements shaping the design and engineering industries. Connect with like-minded professionals, gain insights from industry leaders, and discover groundbreaking tools that can transform the way you work. The energy, innovation, and collaboration at this event are unparalleled, providing the perfect environment to sharpen your skills, expand your professional network, and fuel your creativity.

To help you make the most of your experience, here are just a few sessions we know you won’t want to miss at 3DEXPERIENCE World 2025:

1. Decoding the Mind of a Machine: Exploring Large Language Models & Generative AI

Monday, February 24 | 1:30 PM – 2:15 PM CST

Dive into the fascinating world of Large Language Models (LLMs) and Generative AI in this masterclass designed for all levels. This session offers a comprehensive exploration of the architecture and mechanics behind LLMs, their transformative potential for CAD and design innovation, and the challenges they present—from bias to ethical dilemmas. You’ll leave with a deeper understanding of how these advanced tools are reshaping the future of design.

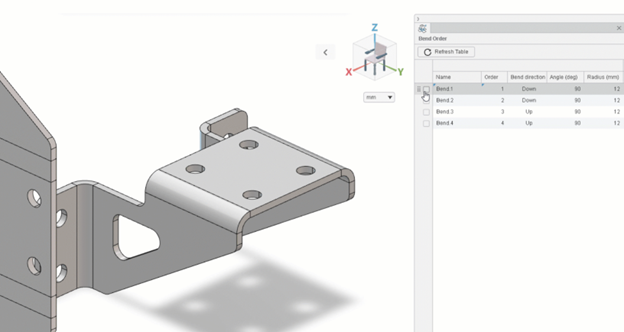

2. Introduction to Smart Components

Tuesday, February 25 | 11:00 AM – 12:30 PM CST

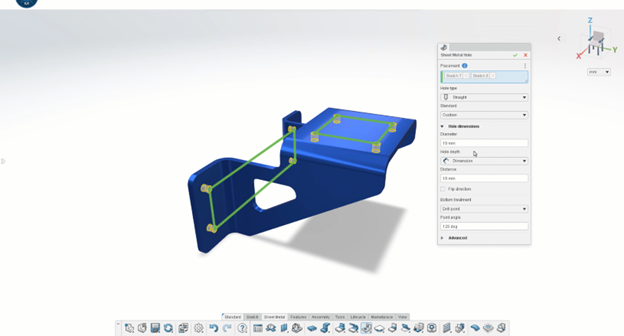

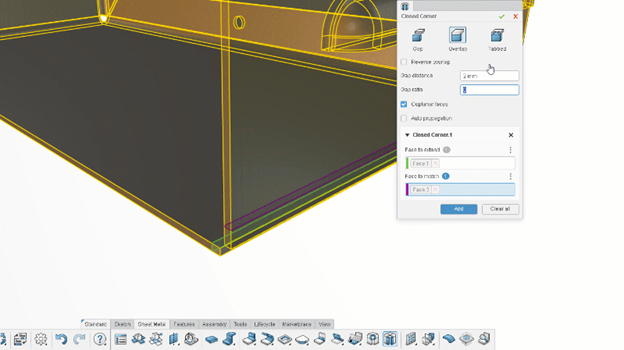

Smart components revolutionize how you incorporate standard hardware into your designs. This beginner-friendly, hands-on workshop will guide you through creating and using smart components that automatically add fasteners and mounting features to assemblies. By simplifying repetitive tasks, this session will empower you to save time and enhance productivity in your day-to-day design workflows.

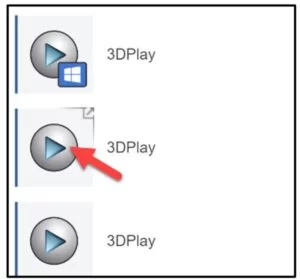

3. Data Matters: Preparing SOLIDWORKS Files for a Smooth Save to 3DEXPERIENCE

Tuesday, February 25 | 1:30 PM – 3:00 PM CST

Preparing your SOLIDWORKS data for migration to the 3DEXPERIENCE platform can be daunting—but it doesn’t have to be. This workshop will teach you data cleaning and preparation techniques using the File Preparation Assistant. Learn how to batch save files, organize bookmarks, and update data seamlessly to ensure a smooth transition. Whether you’re a designer or a CAD manager, this session is a must for optimizing workflows.

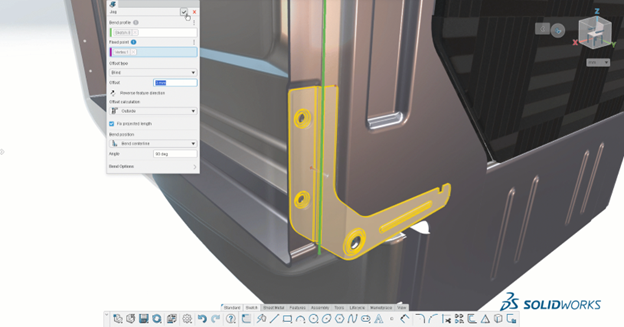

4. The Latest Features to Enhance Your Drafting Workflows

Wednesday, February 26 | 11:15 AM – 12:15 PM CST

With so many new features rolling out every year, it’s easy to lose track of updates that could transform your work. This intermediate session highlights recent enhancements—from big-ticket innovations to hidden gems—that streamline drafting workflows. Learn tips, tricks, and best practices to make the most of SOLIDWORKS and 3DEXPERIENCE updates.

5. Tips and Techniques: Combining Sub-D Surfacing and Parametric Modeling

Wednesday, February 26 | 4:15 PM – 5:00 PM CST

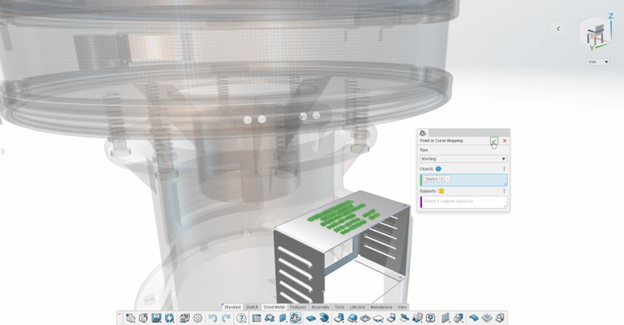

Discover how to blend the artistic freedom of subdivision surfacing with the precision of parametric modeling. This session will demonstrate how to use SOLIDWORKS 3D Sculptor and 3D Creator to create ergonomically optimized designs efficiently. Perfect for intermediate-level designers, this masterclass provides insights into combining these powerful tools to bring your most ambitious designs to life.

Beyond the Sessions

While the sessions are undoubtedly a highlight, 3DEXPERIENCE World 2025 offers so much more. The interactive expo floor is your chance to see cutting-edge technology and tools in action. Meet exhibitors showcasing the latest innovations and get hands-on with products that could redefine your workflows. Additionally, the keynote speeches from visionary leaders in design and technology will provide inspiration and insight into the future of the industry.

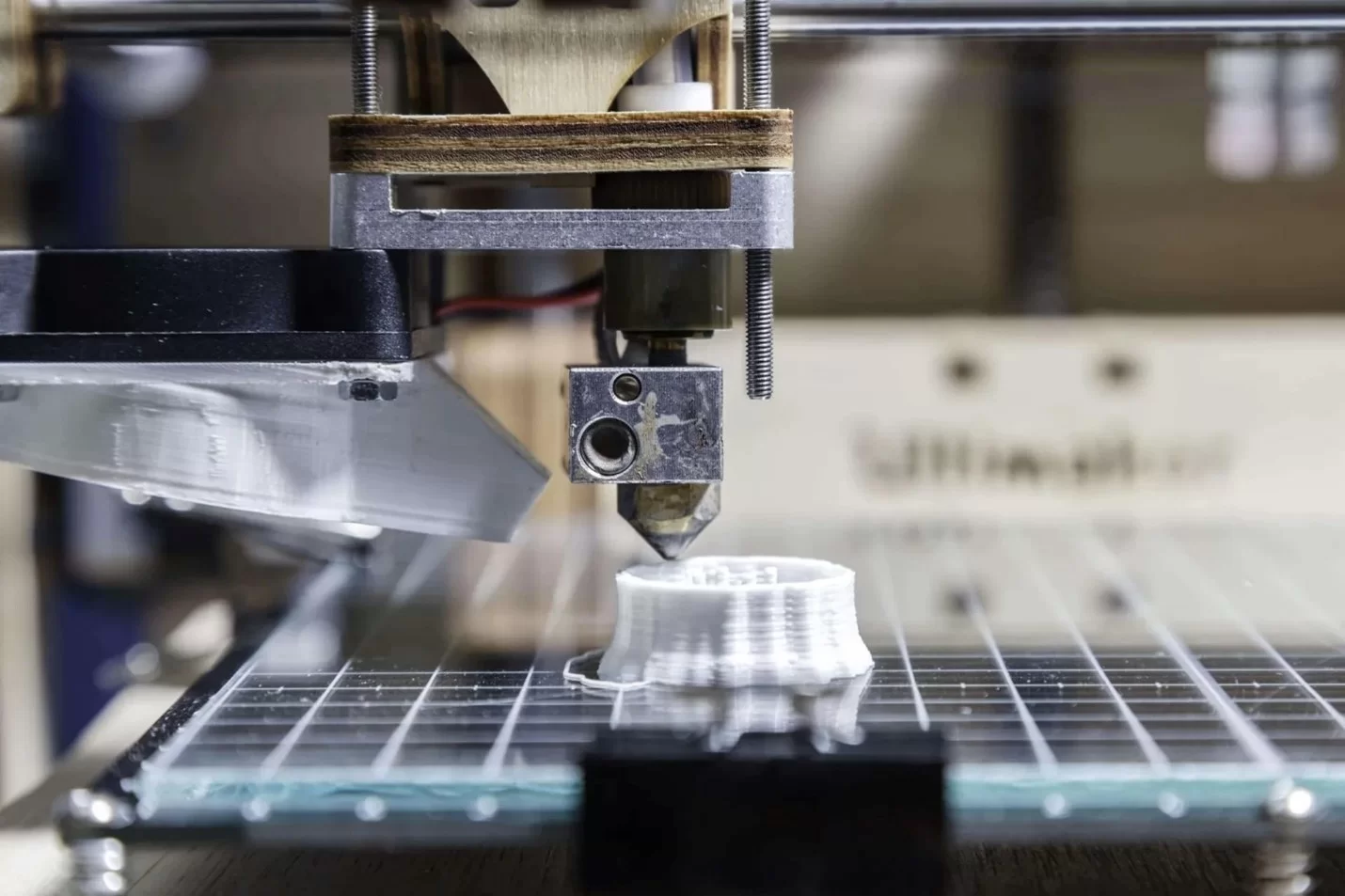

The event also features community meetups and special interest group sessions, where you can dive deeper into topics you’re passionate about and connect with others who share your interests. Whether it’s exploring sustainability in design or learning about the latest in additive manufacturing, these sessions offer something for everyone.

Wrapping It Up

With dozens more sessions than just these 5 that cover a wide range of subjects, 3DEXPERIENCE World 2025 offers opportunities for everyone to grow, learn, and be inspired. From discovering the latest tools to connecting with a passionate community of innovators, this event is your chance to elevate your skills and broaden your horizons. We can’t wait to see you in Houston for what promises to be an unforgettable experience.

Don’t miss your opportunity to be part of this incredible event. Register here and check out the full agenda to start planning your schedule. See you in Texas!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: