This year’s 3DEXPERIENCE World 2026 in Houston brought together the global SOLIDWORKS community. Designers, engineers, students, educators, makers, and executives from all over the world gathered for three days of inspiration, learning, and connection. From powerful keynotes to cutting-edge tech announcements, here’s a highlight reel you’ll want to read.

Day One: Vision, AI, and the Future of Engineering

Day One kicked off with a high-energy General Session that set the tone for the entire event: innovation powered by people and amplified by the right tools. Thousands of attendees gathered to hear leadership from the industry share bold perspectives on where product development is heading.

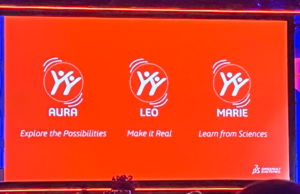

A major theme throughout the day was artificial intelligence (AI). SOLIDWORKS leadership made it clear that AI isn’t a gimmick, it’s already reshaping workflows and helping teams accelerate insight, design, and validation. We saw a live demo of new AI assistants: Aura, Leo, and Marie. Three virtual companions that work together to streamline everything from knowledge context and engineering reasoning to scientific rigor.

-

Aura orchestrates requirements, projects, and changes.

-

Leo brings engineering reasoning to life (mechanics, motion, simulation), think Leonardo da Vinci.

-

Marie applies scientific and regulatory insight, think Marie Curie.

These assistants are designed as companions, not autopilots. They’re tools that let engineers stay in control and design with confidence rather than guesswork.

Later, attendees heard from Pascal Daloz and Gian Paolo Bassi on how a combination of human creativity and connected technology fuels progress faster than ever. One standout message? “Success shouldn’t be judged by speed alone, but by time to value”, meaning design outcomes that are reliable, meaningful, and innovative.

Day One wrapped with a keynote from futurist Pablos Holman, reminding us that the real power of technology lies in solving real world problems, from healthcare to space exploration. His message was forward-looking, inspiring, and grounded in practical impact.

Day Two: Engineering Partnerships and AI in Action

Day Two turned the spotlight to how industry partnerships and technology collaboration are reshaping the way we work. The session opened with Dassault Systèmes CEO Pascal Daloz discussing how a strong engineering community combined with strategic technology partnerships creates innovation that scales.

We heard from Jensen Huang, Founder and CEO of NVIDIA, about the long-standing collaboration between NVIDIA and Dassault Systèmes. Their work emphasizes science-driven AI and virtual twins, paired with high-performance computing to give engineers tools that can handle truly complex systems in simulation and design at scale.

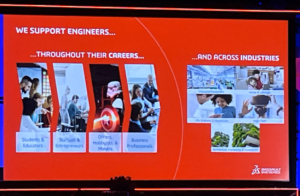

SOLIDWORKS CEO Manish Kumar also joined the stage to outline how AI is being embedded into real design workflows, not as a theory, but as a practical productivity boost. This includes contextual AI tools that help reduce repetitive tasks, free up time for innovation, and bring deeper insight into design decisions.

One of the most exciting themes of Day Two was this: “AI isn’t here to replace engineers; it exists to empower them.” By putting smart tools into your hands, you get faster iteration cycles, fewer errors, and a stronger connection between your design intent and your final product.

Day Three: Community Celebration and the Next Generation

The final day of 3DEXPERIENCE World 2026 was all about community, the people who make this ecosystem special. Whether you’re a seasoned pro, an educator, a student, or a maker, this day celebrated the connections that make innovation possible.

Suchit Jain, VP of Strategy and Business Development, kicked things off by highlighting how collaboration across industry, education, and local innovation hubs builds the workforce of tomorrow. There were strong messages about supporting emerging talent, integrating real-world problem solving into education, and making sure SOLIDWORKS continues to be accessible to innovators of all backgrounds.

Day Three also spotlighted how regional and global communities are using SOLIDWORKS tools to solve real problems, whether that’s in manufacturing, healthcare, education, or startup growth. It was a reminder that technology only reaches its potential when it’s put to work by passionate people.

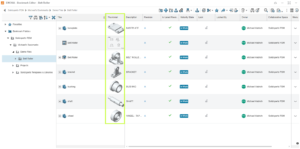

The final sessions included inspiring competition recaps, community-driven breakout sessions, and previews of what’s coming next, including early looks at SOLIDWORKS 2027 features that continue the theme of smarter workflows and tighter collaboration between design, simulation, and data.

What This Means for You

Across all three days of 3DEXPERIENCE World 2026, a few themes stood out loud and clear:

-

Innovation grows when humans and tools work together.

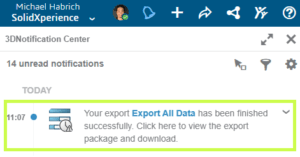

AI companions are here, but they’re companions. They help you work smarter, not replace your expertise. AND the best part, they come with SOLIDWORKS with Cloud Services. -

Connected ecosystems : partnerships + community to accelerate progress.

Whether it’s NVIDIA, startups, educators, or global manufacturers, connection drives insight at scale. -

The next generation of designers is in focus.

Programs, hubs, and community efforts are investing in future creators, ensuring SOLIDWORKS tools remain integral to how engineering gets done in the years ahead.

3DEXPERIENCE World 2026 wasn’t just a conference, it was a reminder of why we design, why we connect, and why we build communities around shared purpose, problem solving, and progress.

We’re already looking forward to 3DEXPERIENCE World 2027!

If you want to know more about how SOLIDWORKS users can begin to leverage AI in 2026, call us, or visit at 2650 Avenue Marie-Curie, QC.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: