Artificial intelligence (AI) is playing an increasingly important role in engineering processes, particularly when it comes to automating repetitive tasks and accelerating the production of technical documentation. However, its role remains fundamentally complementary to that of engineers. Creativity, domain expertise, and decision-making responsibility remain human.

In this article, we explore:

-

what AI concretely brings to engineering

-

which tasks remain (and will remain) human

-

how to organize an effective human–machine collaboration

-

and what this means for the engineering profession

1. What AI concretely brings to engineering

1.1 Automating repetitive, low-value tasks

The daily work of engineering teams is filled with essential but repetitive tasks that consume a great deal of time without fully leveraging engineers’ expertise. This is precisely where AI excels.

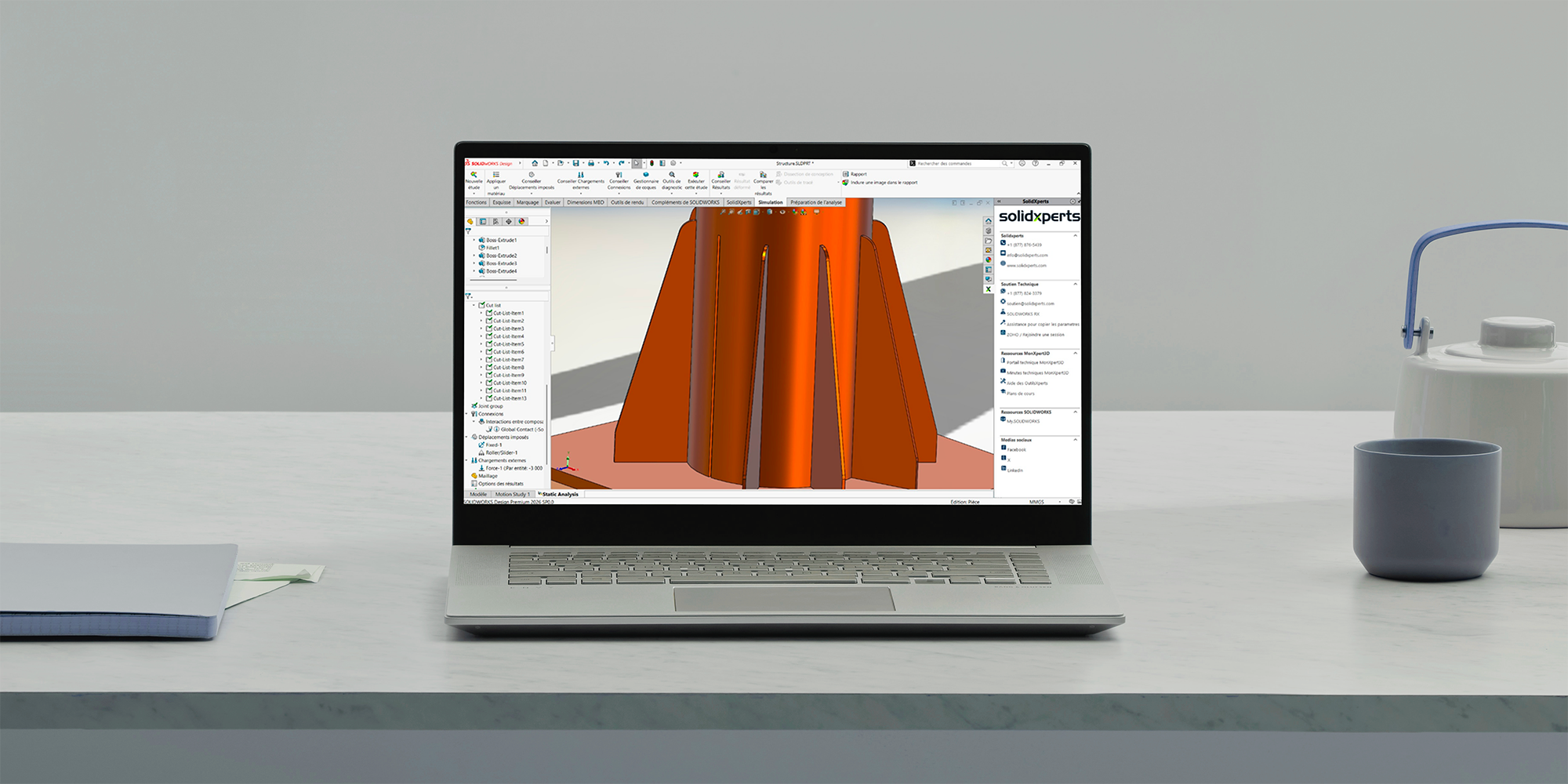

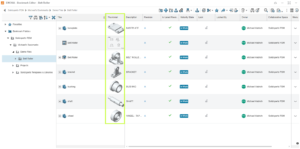

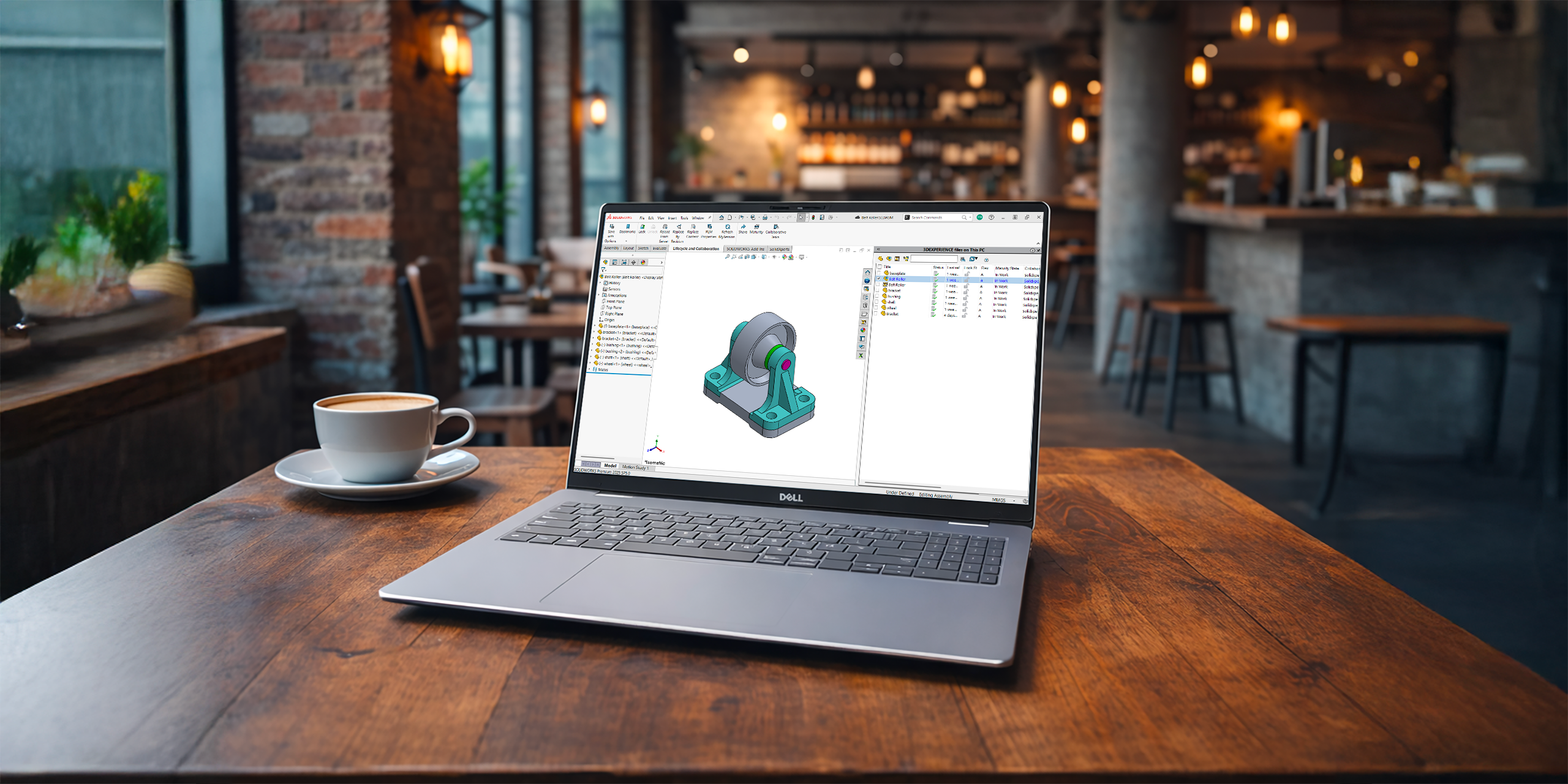

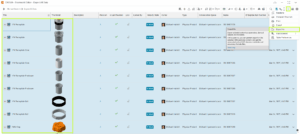

A typical example is generating technical drawings from 3D models.

Traditionally, producing technical drawings involves:

-

manually creating the different views (front, section, detail views)

-

applying dimensioning and tolerancing standards

-

reusing elements from previous projects, often manually

-

performing successive checks for consistency and compliance

With AI, a large portion of this work can be:

-

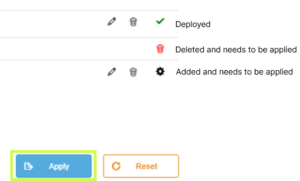

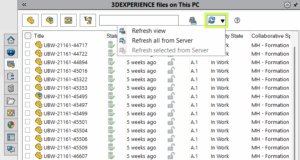

automated: generating technical drawings directly from 3D designs

-

contextualized: taking into account company history, internal standards, and previously validated models

The result: fewer repetitive clicks and more time for analysis and improvement.

1.2 Measurable efficiency gains

The operational impact is far from marginal.

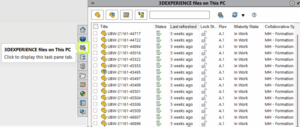

Where dozens of people were previously needed to produce, adjust, and verify detailed drawings, organizations can now concentrate human work within a smaller team of reviewers responsible for:

-

correcting the remaining inconsistencies

-

validating compliance

-

managing special cases not covered by the models

AI handles the repetitive heavy lifting. Humans focus on quality, reliability, and exception management.

2. Tasks that remain (and will remain) human

Despite these gains, certain activities remain difficult to automate and may remain so in the short and medium term.

2.1 Creative design and early project phases

The early stages of a project, when the architecture of a product and the major technical choices are defined, rely on:

-

creativity

-

accumulated domain expertise

-

the ability to integrate sometimes ambiguous constraints (real-world usage, environment, maintenance, ergonomics)

-

complex decision-making that affects overall product performance

These activities require systemic understanding, multi-criteria trade-offs, and a form of intuition that current AI models cannot replicate.

2.2 Safety, compliance, and responsibility

A clear example is the design of powerful machinery.

Engineers must:

-

integrate safety factors to protect users

-

sometimes introduce additional margins based on experience or real-world conditions that are difficult to simulate

These decisions directly affect safety, regulatory compliance, and legal responsibility.

Today, these types of decisions cannot be delegated to AI.

Decision-making responsibility remains with humans, not algorithms.

3. Toward intelligent human–machine collaboration

The key question is therefore not whether AI will replace engineers, but how to organize an effective collaboration between the two.

3.1 AI as a copilot during design

During the design process, AI can act as a copilot or technical assistant. For example, it can:

-

propose lighter materials that still meet strength requirements

-

suggest geometric variations to reduce weight or improve rigidity

-

quickly analyze the impact of small design changes on overall performance

In practice, engineers can ask AI questions such as:

-

“Which materials meet these strength and weight constraints?”

-

“What geometric alternatives could reduce the mass by 10 percent?”

However, final validation, trade-off decisions, and system integration remain the responsibility of the engineer.

3.2 AI as an analyst for standardized tasks

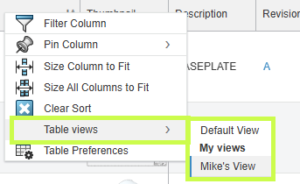

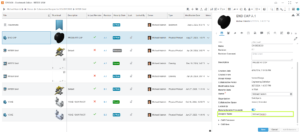

For more standardized analytical tasks, AI becomes a particularly useful engineering assistant. It can support:

-

the processing and structuring of large volumes of data

-

the automatic generation of variants for comparative studies

-

consistency checks across large sets of technical documentation

This allows teams to explore more possibilities in less time, without removing the engineer from the decision-making process.

4. Should engineers fear being replaced by AI?

The fear of being replaced by machines is real and understandable, especially in technical professions.

4.1 Vulnerable jobs vs resilient jobs

A job is more exposed to automation when its tasks are:

-

repetitive

-

highly standardized

-

not very creative

-

associated with limited decision-making

In contrast, a job is more resilient when it involves:

-

significant creativity

-

a global understanding of complex systems

-

multi-criteria trade-offs (cost, performance, risk, environmental impact)

-

strong responsibility for safety, compliance, or performance

In engineering, activities such as:

-

defining a product’s overall architecture

-

breakthrough innovation

-

high-impact technical decisions

-

field responsibility

remain firmly within the human domain.

4.2 A change in role rather than disappearance

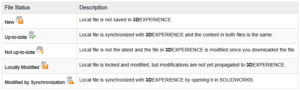

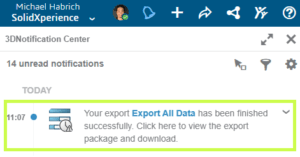

Consider the example of technical documentation.

Yes, AI can generate documents based on validated models or historical data.

No, it does not replace engineers when it comes to:

-

critical decision-making

-

technical trade-offs

-

creative innovation

What changes most is how time is allocated:

-

less manual and repetitive production work

-

more design, analysis, validation, and innovation

Toward augmented engineering, not automated engineering

Artificial intelligence brings real value to engineering by:

-

automating repetitive, low-value tasks

-

accelerating the generation of drawings and technical documentation

-

assisting engineers in exploring design alternatives and performing analysis

However, creativity, domain expertise, and responsibility remain central to the engineer’s role.

The goal is not to replace humans, but to build intelligent collaboration:

-

letting AI handle what it does best (speed, repetition, scale)

-

preserving what defines engineering expertise: inventing, evaluating trade-offs, and taking responsibility for decisions

The future of engineering will not be “human or AI,” but clearly human + AI: augmented engineering that is more efficient, safer, and more focused on innovation.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: