When we talk about AI, certain fears arise: could AI replace the engineer or the designer? The answer is no. Dassault Systèmes’ philosophy is very clear: AI does not replace, it enhances. After 11 years at S0lidxperts and more than 15 years of using SOLIDWORKS, I am well aware of this fact.

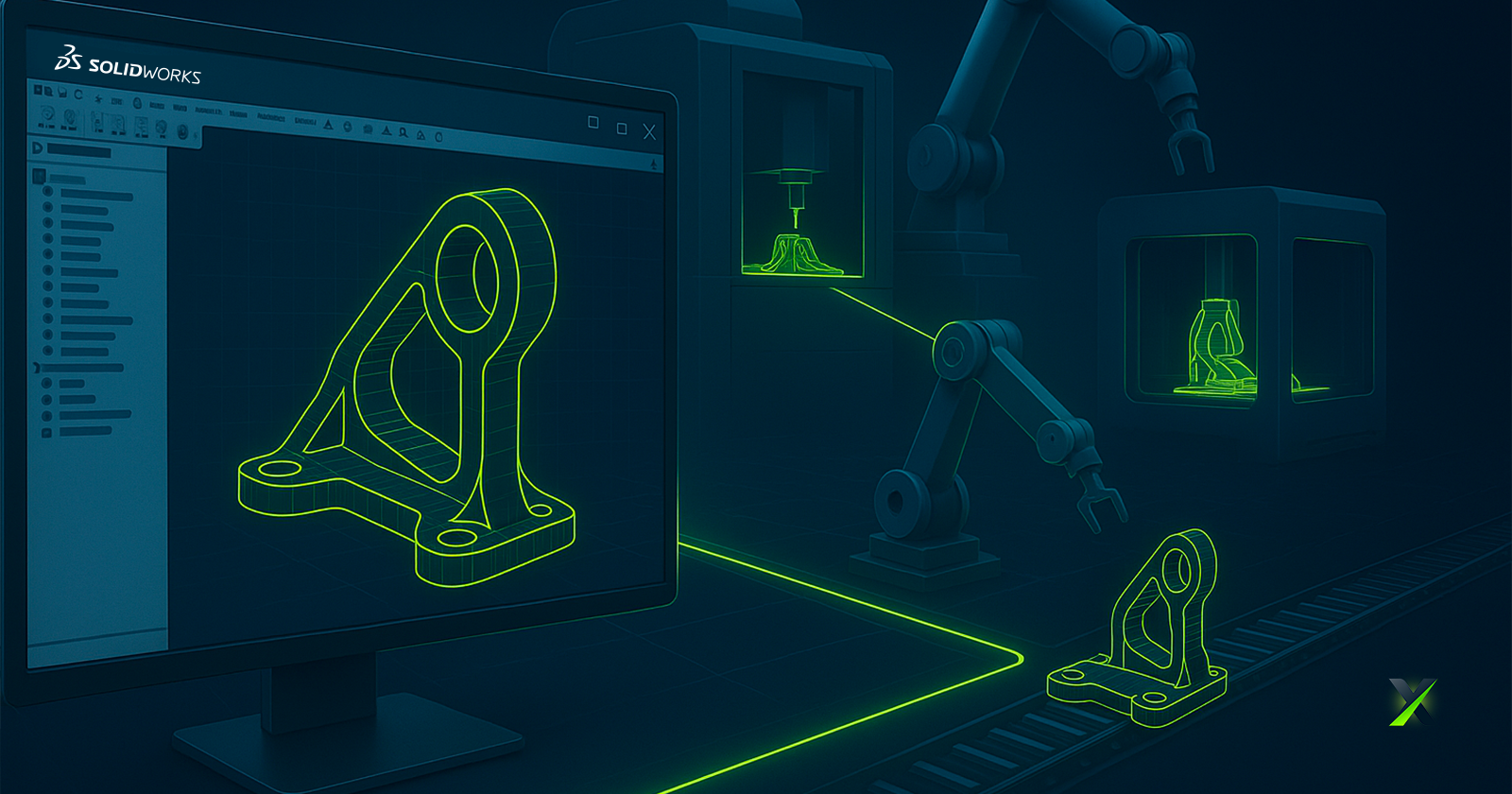

SOLIDWORKS, one of the most trusted CAD platforms globally, has already begun integrating AI-driven tools that assist engineers in reducing repetitive tasks, improving design quality, and accelerating time-to-market. Through the 3DEXPERIENCE platform, Dassault Systèmes is also paving the way for AI-powered collaboration and predictive design in the cloud.

In this article, we’ll explore how AI is shaping the present and future of SOLIDWORKS, highlight the business benefits, and share how Solidxperts, over 40 years in the industry and more than 25 years as a SOLIDWORKS partner, supports companies in embracing this transformation.

1. AI in SOLIDWORKS: An Engineer’s New Ally

Dassault Systèmes’ vision has always been clear: AI does not replace engineers. It enhances their capabilities. For decades, SOLIDWORKS has incorporated automation features designed to simplify CAD workflows:

-

Smart Mates for automatic assembly constraints.

-

Command Prediction suggesting the most likely next tool.

These were early steps toward intelligent CAD. Today, SOLIDWORKS goes further with AI-driven assistants like Design Assistant, and cloud-based tools powered by machine learning through the 3DEXPERIENCE platform.

The philosophy is simple: let AI handle the repetitive and time-consuming tasks, so engineers can focus on innovation, creativity, and solving real engineering challenges.

2. Current AI-Driven Features in SOLIDWORKS

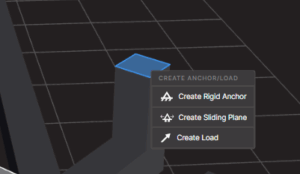

a) Design Assistant

-

Mate Helper and Selection Helper: automatically detects similar components and applies constraints, drastically reducing clicks in large assemblies.

-

Example: When assembling dozens of fasteners, Design Assistant identifies similar geometry and instantly applies consistent mates.

b) Automatic Drawings (SOLIDWORKS 2025)

-

Automatically generates 2D drawings from 3D models.

-

Ensures compliance with drawing standards.

-

Saves significant time in documentation, especially for design offices managing large projects.

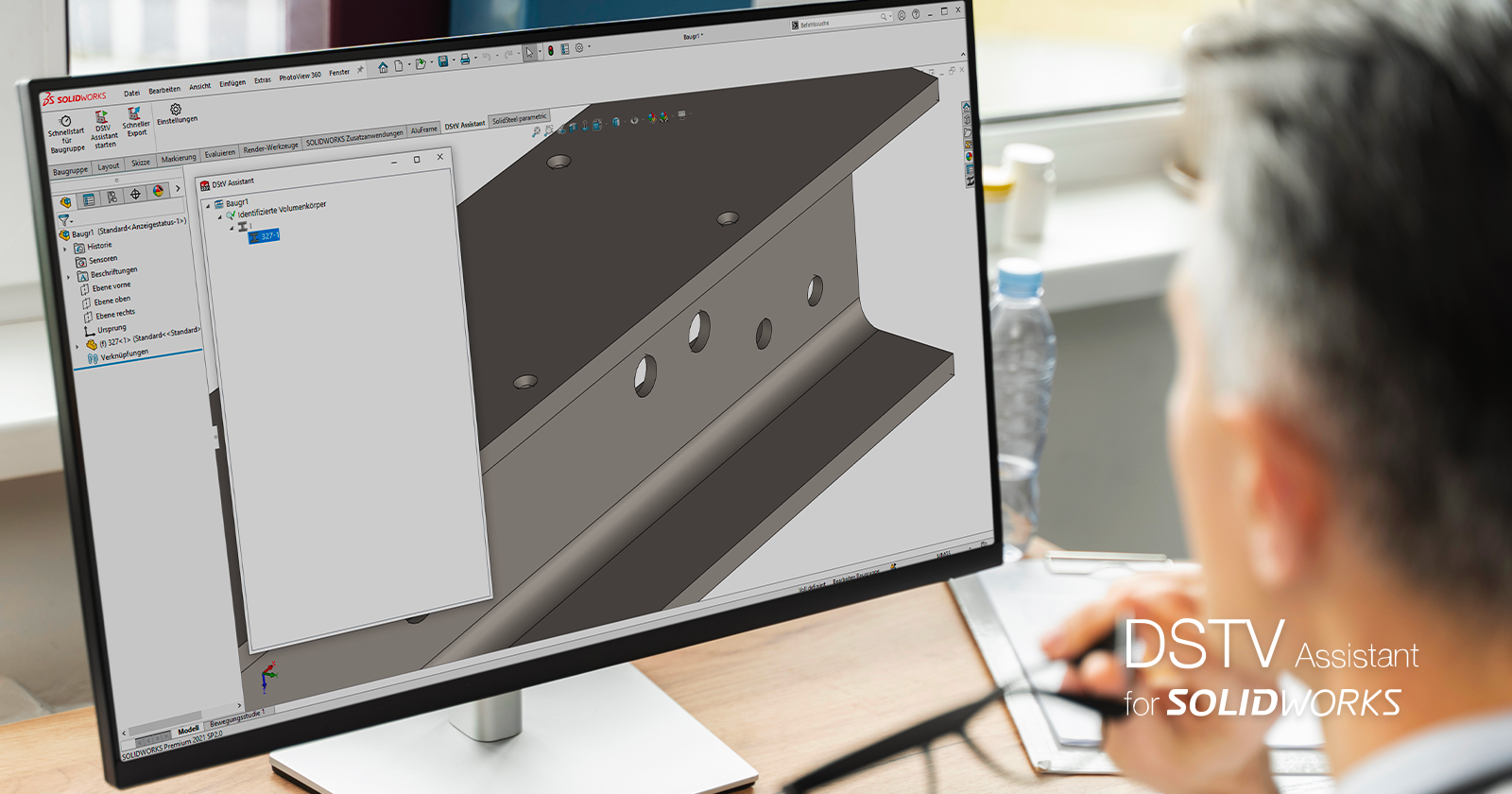

c) Fastener Recognition (FD03)

-

Automatically detects standard fasteners in assemblies.

-

Applies appropriate mates without manual intervention.

-

Direct impact: reduced errors, fewer repetitive operations.

d) AURA: The Conversational AI Assistant

-

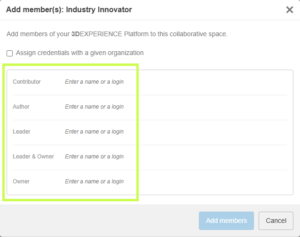

Integrated into the 3DEXPERIENCE platform.

-

Provides contextual guidance to users, learns from workflows, and offers predictive insights.

-

Example: guiding new users through advanced features or assisting with design standards.

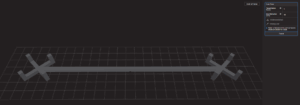

3. The Future of AI in SOLIDWORKS: A Roadmap

Dassault Systèmes continues to push boundaries, and the AI roadmap promises groundbreaking advancements:

-

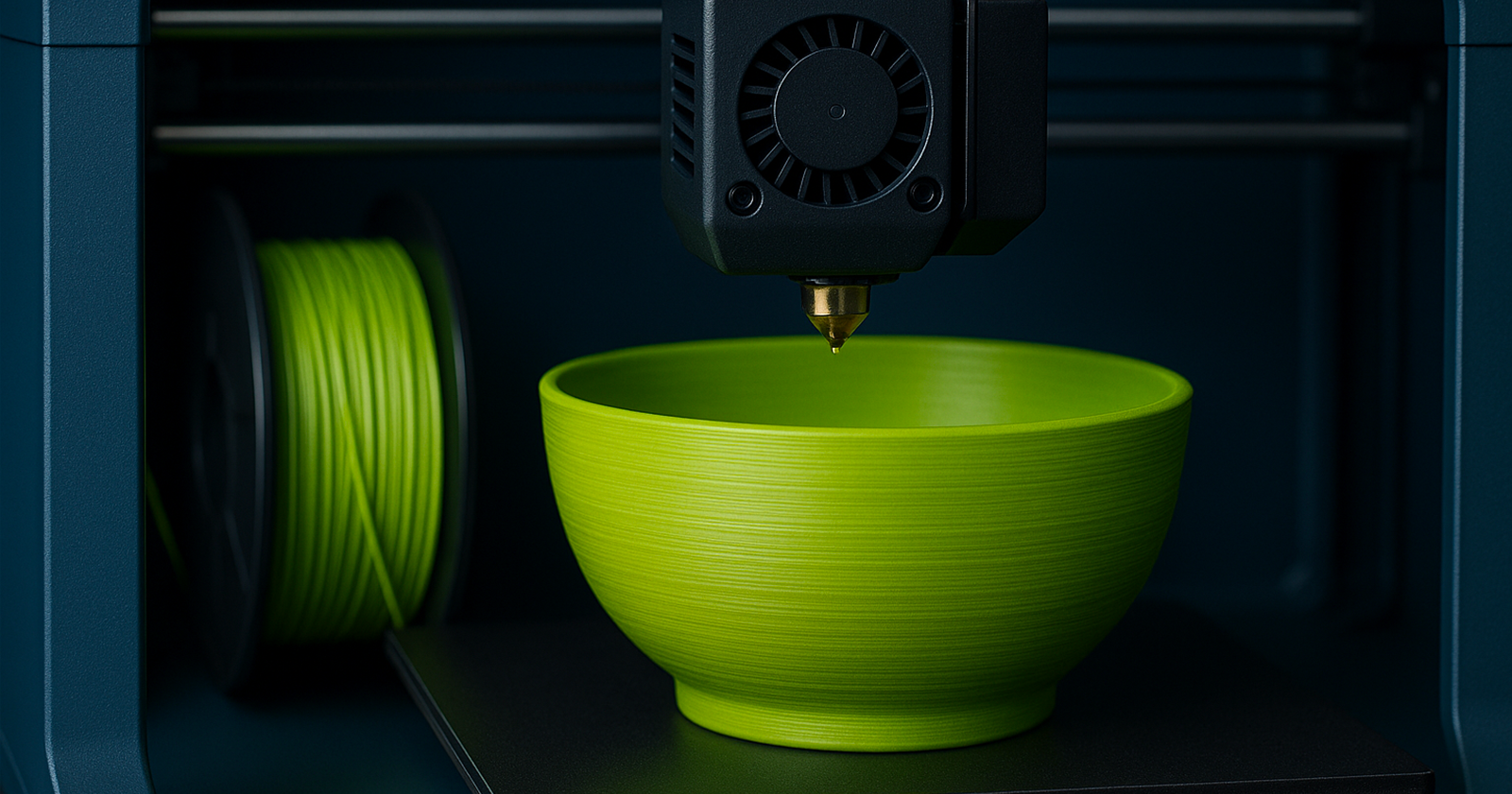

Mesh to Parametric Conversion (Reverse Engineering): AI will streamline converting mesh files into fully parametric models, accelerating reverse engineering processes.

-

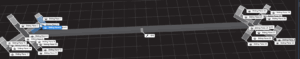

AI-Optimized Assemblies: Automatic detection of redundant constraints, performance optimization, and manufacturability checks.

-

AI-Generated Photorealistic Renders: Leveraging generative AI to instantly create marketing-ready visuals without lengthy manual rendering.

-

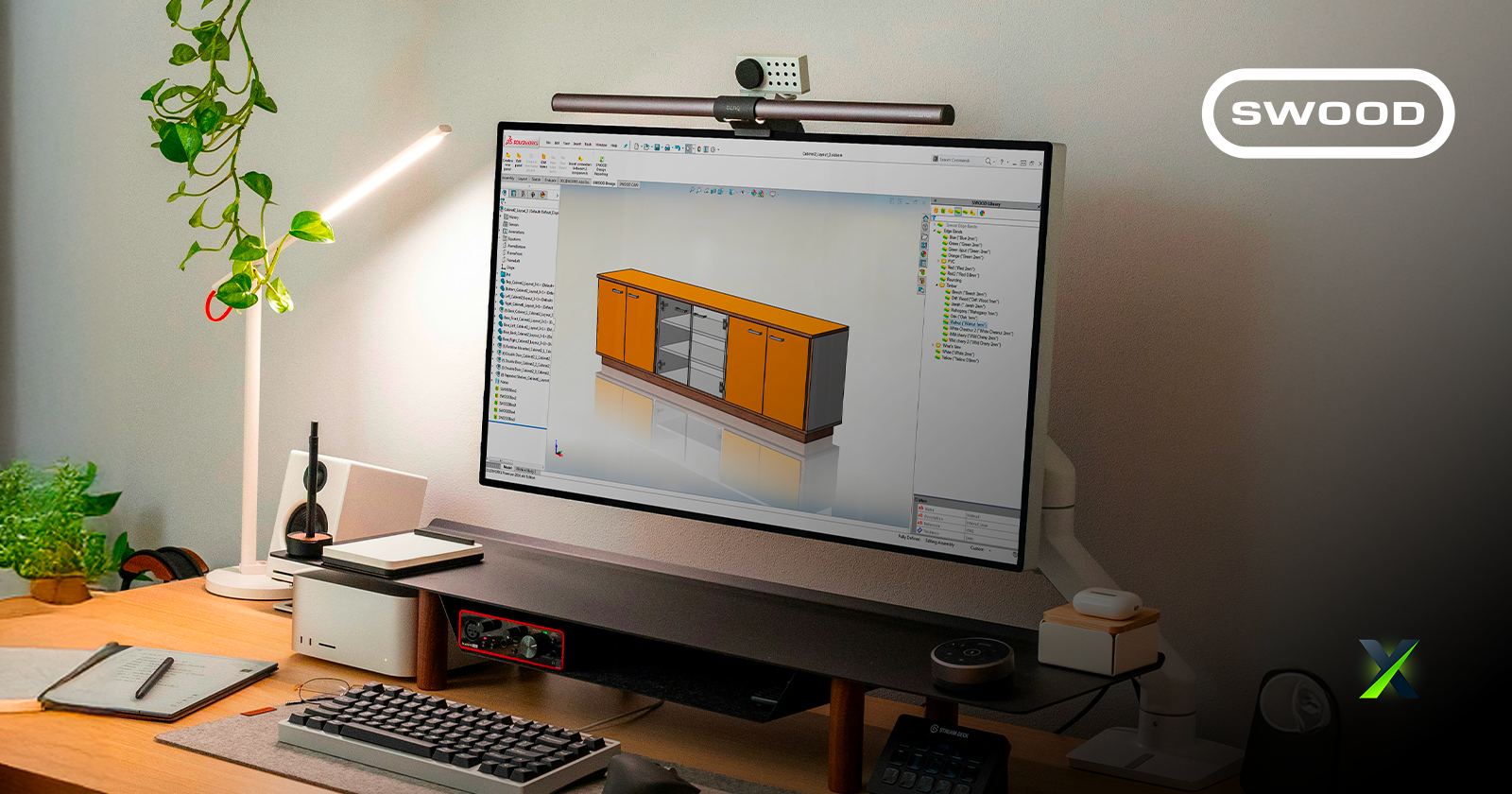

xDesign and Cloud-Ready AI: The 3DEXPERIENCE xDesign app represents the next generation of CAD: cloud-based, AI-enhanced, and fully collaborative.

-

Vision: Predictive, Collaborative CAD: An environment where the system anticipates design intent, suggests optimizations, and improves with each project.

4. Strategic Benefits for Companies

Adopting AI in SOLIDWORKS is not just about convenience—it drives measurable business impact:

-

Productivity: Significant time savings through automation of repetitive tasks.

-

Quality: Consistent designs, fewer human errors, and adherence to standards.

-

Innovation: Engineers gain more time to focus on R&D and creative problem-solving.

-

Competitiveness: Faster time-to-market and optimized workflows lead to a competitive edge.

Use Cases:

-

Design offices managing large assemblies save hours on constraints.

-

Manufacturers preparing technical documentation see accelerated drawing creation.

-

Teams leveraging AURA gain training efficiency and reduced onboarding time.

5. Data Security and Confidentiality

AI adoption often raises concerns about data protection. Dassault Systèmes has addressed this head-on:

-

Your proprietary data is not shared or trained externally without explicit consent.

-

Companies can configure private AI models trained on their own part libraries and workflows.

-

This ensures both innovation and confidentiality which is critical for SMEs and global enterprises alike.

6. Solidxperts: 40 Years of Experience, Always Evolving with AI

The evolution of Solidxperts over the past four decades reflects the same philosophy as SOLIDWORKS: constant growth, adaptation, and customer focus.

-

1998: Solidxperts opened its main office in Montreal, introducing clients to SOLIDWORKS back then, delivered on physical CDs.

-

Today: Solidxperts delivers the full Dassault Systèmes portfolio, from SOLIDWORKS to the cloud-based 3DEXPERIENCE platform, supporting every step of the design-to-manufacturing journey.

-

Values: transparency, dedication to customer success, and a personalized approach embedded in every interaction.

-

Expansion: with offices in Quebec City (QC) and Nashua (NH), Solidxperts serves engineers and businesses across Eastern Canada and New England.

This long-term experience positions Solidxperts as the partner of choice for companies looking to adopt AI-powered CAD and manufacturing solutions.

The Future is Now with SOLIDWORKS AI

Artificial Intelligence is no longer an abstract concept. Iit is already part of the tools engineers use daily in SOLIDWORKS. From automated mates to predictive design and cloud collaboration, AI is redefining the engineering experience.

For businesses, embracing AI in SOLIDWORKS means:

-

Faster workflows

-

Fewer errors

-

More time for innovation

-

Stronger market competitiveness

At Solidxperts, we’ve supported thousands of engineers and companies for over 25 years with SOLIDWORKS, and we are ready to help you take the next step: integrating AI into your design and manufacturing workflows.

Contact our experts today to schedule a personalized demo and discover how AI in SOLIDWORKS can transform your business.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: