written by Steven Murphy – Certified SOLIDWORKS Expert (CSWE)

Markforged transformed the 3D printing industry back in 2013 with the ability to create functional industrial parts. While this 3D printing powerhouse innovates with metal 3D printing, we want to take a moment to recognize the powerful features offered by the composite printers that keep them at the top of the FDM world. Here are our top seven Markforged composite features:

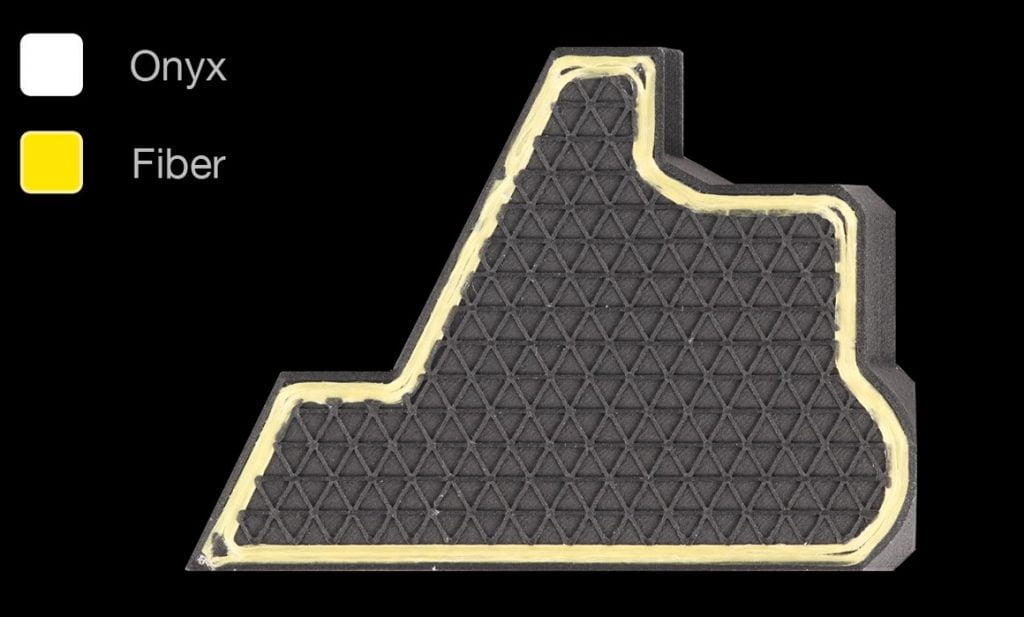

1. Fiber

This is the go-to innovation for the Markforged printers – the ability to print with Continuous Fiber Filament (CFF) using Fiberglass, Kevlar, and everyone’s favorite, Carbon Fiber.

Impact:

3D printed parts 8x stronger than ABS with comparable traits to 6061 Aluminum unlocks design possibilities. Lighter parts with low cost and fast production can be a valuable proposition for many manufacturers. This feature single-handedly allows 3D printing to be a comprehensive solution rather than a prototyping tool.

2. Expand Thin Features

What exactly does “Expanding Thin Features” do? Enabling this feature will thicken your part geometry to meet the minimum wall thickness requirements of the printer. It will automatically take any layer that is too thin to print and adapt it to meet the minimum requirements. Easily overlooked as it only takes one click to activate, you can see the part salvaged in the slice views below!

Impact:

This feature really excels at taking parts not designed for additive manufacturing and adjusting their geometry to be 3D-pintable. You need to be careful when using this feature as changing the geometry does not maintain the dimensional accuracy of the original CAD model. The major upside is that the majority of legacy parts can be printed on Markforged printers without any major redesign. This level of automation and intelligence is a huge jump in innovation in an otherwise stale industry.

3. Pause & Remove the Print Bed

The print bed itself is fastened by three neodymium magnets, allowing the user to remove the build plate during any layer. This also means that you can replace the print bed and continue the print from where you left off. This process has a repeatability of 10 microns, meaning there are no issues in continuing the print from the new position.

Impact:

Being able to pause and remove the print bed opens up many design options such as embedding hardware or enclosing secondary parts (eg. LED, magnets, or RFID). The repeatability and consistency of the print bed enables many tricks and are well documented in the Markforged blogs.

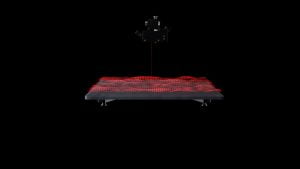

4. Adaptive Bed Leveling (X7)

The X7 Industrial printer utilizes a built-in laser micrometer to create a contour map of the print bed with 1µm accuracy. While it will alert you to the bed not being leveled correctly, more importantly, the printer will dynamically adjust the extrusion of the first layer to increase the consistency of your print.

Impact:

The application of the laser measuring system eliminates many of the bed leveling issues that occur with standard FDM style printers. Not only are the parts flatter than traditional FDM printers, but the initial compensation means significantly fewer failed prints.

Bonus: Blacksmith

Check out the Blacksmith AI that takes advantage of the same laser micrometer to adjust the physical part based off of inspection results. The end result is a tight feedback loop that makes extremely accurate parts that become more accurate over time.

5. Turbo Print & Turbo Supports [BETA Features]

The Turbo BETA features allow for support and infill to be printed at twice the layer height of the print. By taking advantage of the support structure, Markforged has increased opportunities to save time and material on your prints.

Impact:

The turbo features allow for faster print times and reduces material. Fundamentally, it shows that Markforged is committed to improving and implementing solutions. They are willing to continuously improve their product, and will continue to add BETA features.

6. Eiger Dashboard

With a versatile cloud based software, there many metrics tracked for your convenience. The Eiger Dashboard allows for both management and users to track printer statistics such author and material usage. Not only does the portal include integrated graphics, but the data is also available as a CSV.

Impact:

In traditional manufacturing, material and time management are a huge part of resource management. Using Eiger, it is incredibly easily track material usage, up-time, and other valuable metadata to make your operation more efficient.

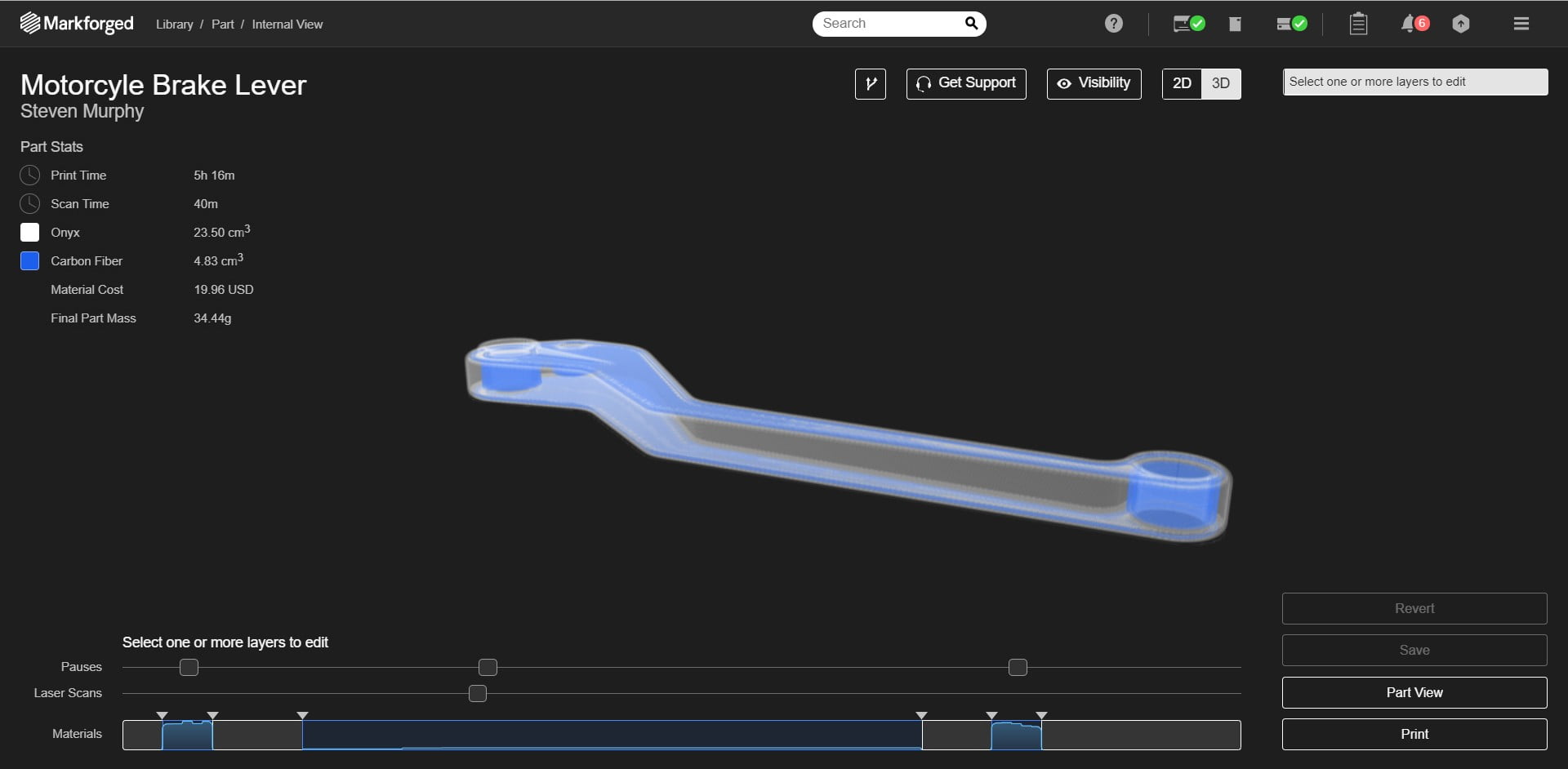

7. Eiger Internal View

With the Eiger “slicer”, users can view the internal features of your part in both 2D and 3D. These views also include the thermoplastic structure, infill, use of fiber, and removable supports. Additionally, the slicing view includes a live slider, which reflects print time and material usage by layer. The best feature when using the internal view is the ability to add and adjust fiber layers (blue sections).

Impact:

When enabling fiber usage in Eiger, the standard automation of fiber reinforcement does an exceptional job. However, the ability to control fiber layer placement gives you, the user, the option to add strength to the part without overcompensating with fiber or increasing unnecessary part cost. With clever orientation and fiber layouts, you can create very strong, yet cheap parts! Need bolt holes strengthened to resist shear stress? No problem! Want to take advantage of beam bending theory to reduce cost? Takes only a few clicks. This adaptability and maneuverability in the internal view make this one of the highest impacts features with the Markforged printers.

Conclusions:

So there you have it – The key features Markforged composite printers have to offer. Even though FDM style printing is a known quantity, Markforged has managed to innovate on key features that keep the technology fresh.