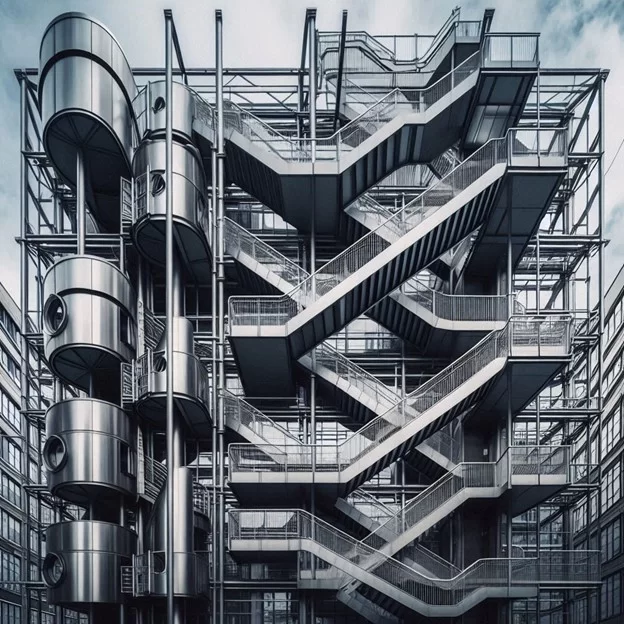

Stairs and railings are not just functional building elements but style statements, engineering marvels, and safety features. From grand hotel staircases to modern urban railings, they enhance aesthetics and usability. SolidSteel parametric solves the unique design and engineering challenges for these structures seamlessly in your familiar SOLIDWORKS environment.

In this article, we’ll explore the intricate challenges of designing modern stairs and railings, the creative solutions available to engineers and designers, and how SolidSteel parametric provides the tools needed to bring these complex designs to life.

The Dual Role of Stairs and Railings

Modern stairs and railings serve a dual purpose. Aesthetically, they can define the character of a building, drawing the eye and creating a visual narrative that guides visitors through a space. Structurally, they must meet rigorous safety standards, support significant weight, and integrate seamlessly with the overall architecture. Achieving this balance between form and function requires both creative vision and technical expertise.

Aesthetic Considerations

Designing stairs and railings is an exercise in creativity. Architects and designers must consider materials, shapes, lines, and proportions to create elements that enhance the visual appeal of a space. Whether it’s a minimalist floating staircase or an ornate wrought-iron railing, the design must complement the building’s overall aesthetic.

Structural Considerations

On the engineering side, stairs and railings must adhere to strict safety codes and structural requirements. They need to be strong enough to support constant use, resistant to wear and tear, and capable of being manufactured with precision. This is where the challenges multiply—especially when dealing with complex geometries, custom designs, and varying materials.

To know more about the broader toolkit of SolidSteel parametric, or to explore the difference between SolidSteel and SOLIDWORKS Weldments, check out our previous articles!

Challenges in Designing Stairs and Railings

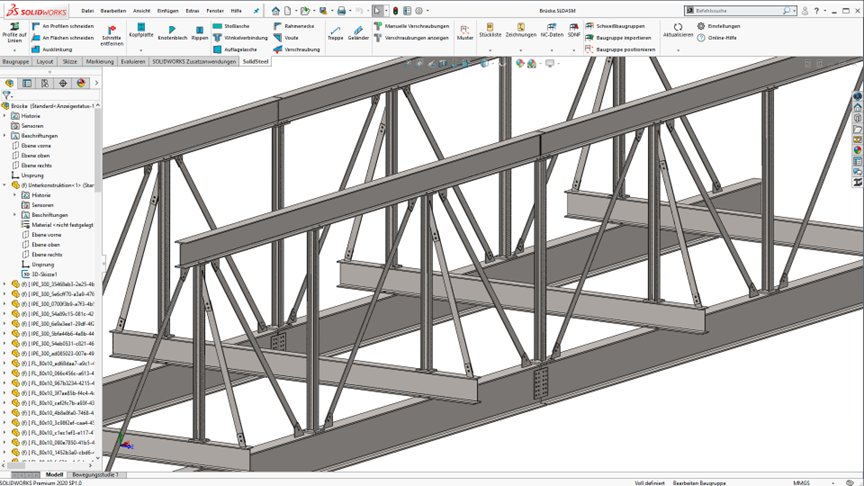

- Complex Geometries: Modern architectural designs often feature non-linear or floating staircases that challenge traditional design methods. These geometries require precise calculations and intricate detailing to ensure both structural integrity and aesthetic beauty.

- Material Choices: Steel is a popular material for modern stairs and railings due to its strength and versatility. However, classic steelwork requires specialized tools that can handle the unique properties of the material, including its weight, weldability, and resistance to corrosion.

- Safety and Compliance: Engineers must ensure that every stair and railing system complies with local building codes and safety standards. This includes calculating load-bearing capacities, ensuring proper spacing between balusters, and designing handrails that are both sturdy and comfortable to use.

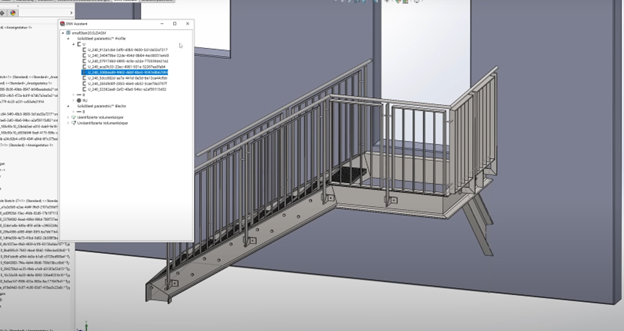

- Customization Needs: No two projects are alike, and customization is often required to meet the specific needs of a building’s design. This means creating custom profiles, connections, and fittings that not only match the aesthetic vision but also meet structural requirements.

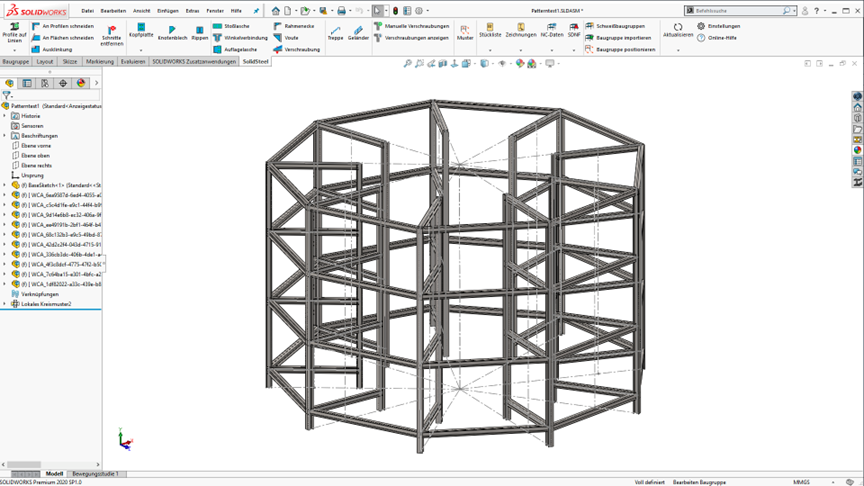

How Does SolidSteel Parametric Solve These Challenges?

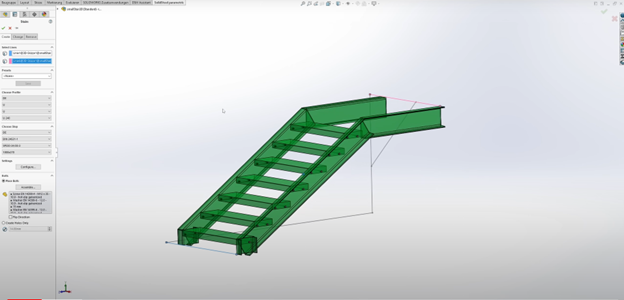

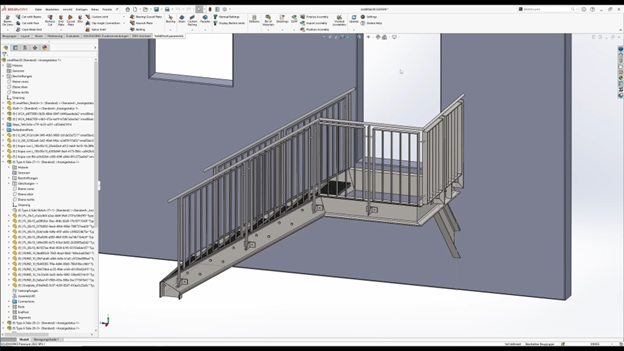

- Advanced Stair and Railing Design Tools: Specialized tools for designing intricate staircases and railings streamline the creation of precise, customizable components with automated features that simplify stair and railing geometry intricacies. So, you can focus on creativity without the guesswork.

- Custom Profile Creation and Management: Customization is key. SolidSteel parametric allows you to create and manage custom profiles, ensuring that every element of a stair or railing system can be tailored to the specific needs of a project. This flexibility is crucial when working on larger designs that require both standard parts and non-standard components or have unique aesthetic features.

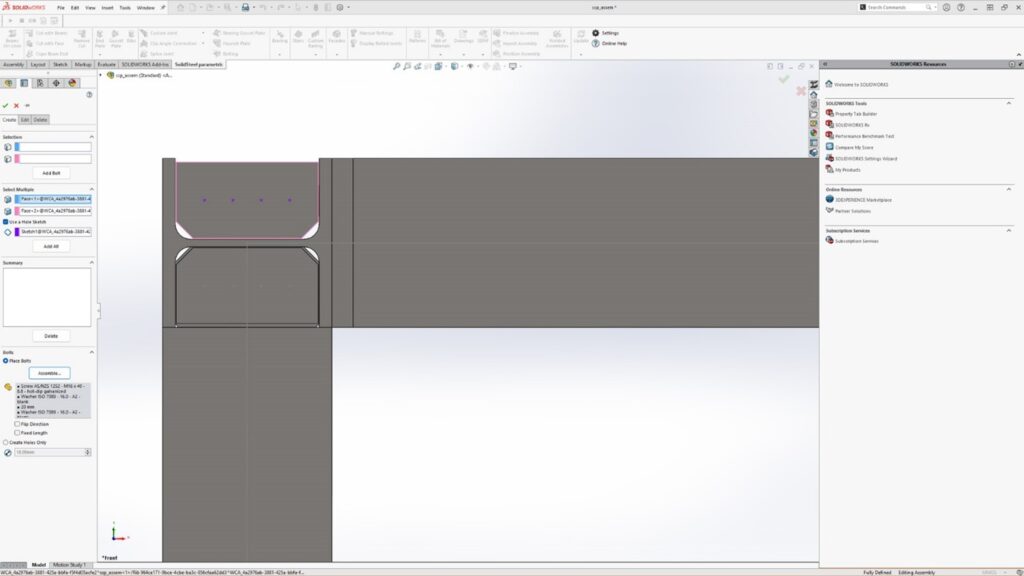

- Automated Connection Design: One of the most challenging aspects of designing stairs and railings is ensuring that all connections are secure, compliant, and easy to fabricate. SolidSteel parametric automates the connection design process, generating precise, detailed connections that meet structural requirements while maintaining the design’s aesthetic integrity.

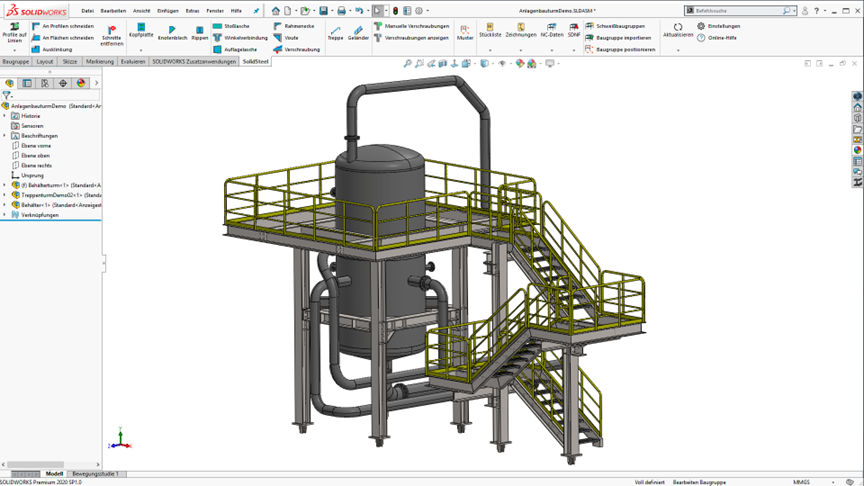

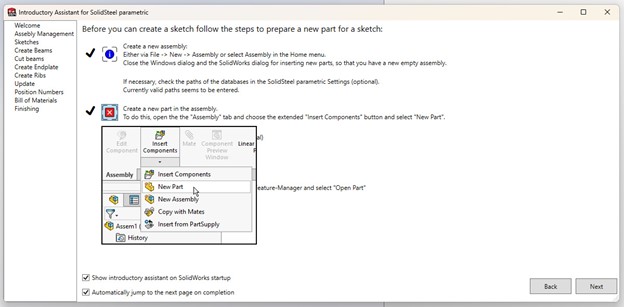

- Integration with SOLIDWORKS: Leverage your familiar SOLIDWORKS user interface while accessing advanced structural steel design tools, making the workflow more efficient and intuitive.

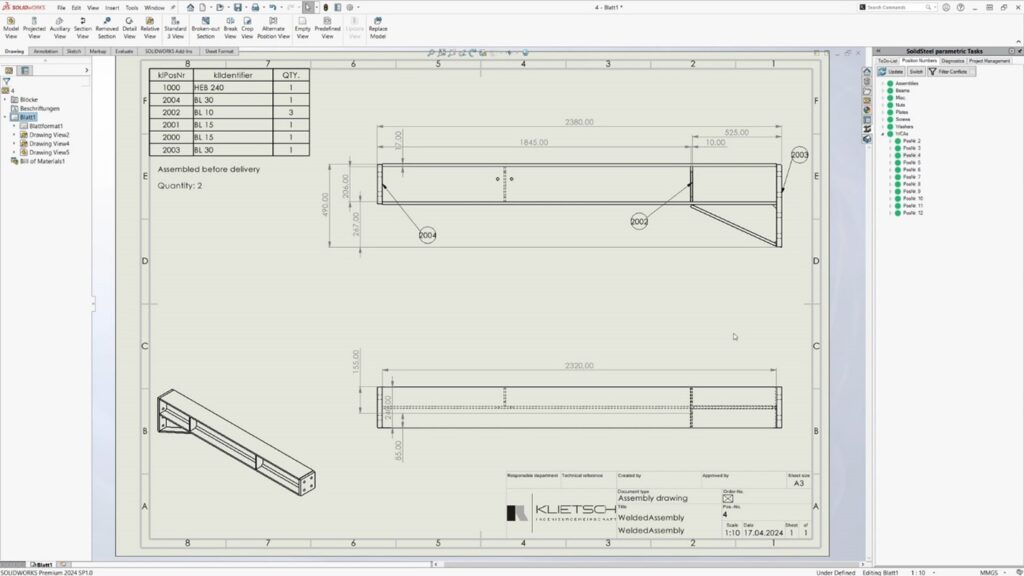

- Detailed Production Drawings and Documentation: Generate detailed production shop drawings and documentation. This includes everything from cut lists to assembly instructions, ensuring that every component is fabricated and installed with precision.

The Value of SolidSteel in Modern Stair and Railing Design

Does SolidSteel Deliver Complex Designs Faster?

Yes. Designing stairs and railings can be complex and time-consuming, but SolidSteel parametric simplifies the process. It automates profile creation, connection design, and structural analysis for steel connections in assemblies.

Can SolidSteel Minimize Errors and Maximize Safety?

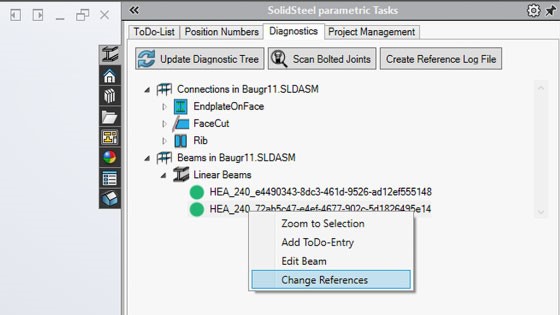

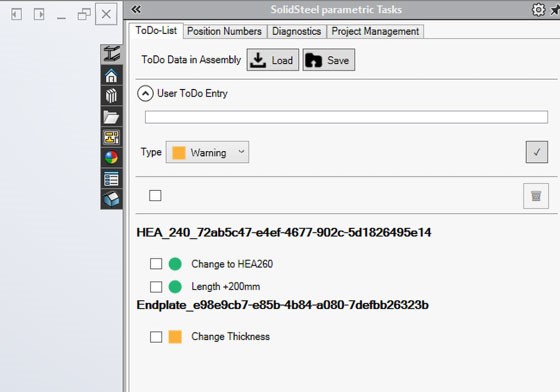

Yes, again! SolidSteel parametric provides the right tools for error-free designs that meet safety standards. Real-time insights on load-bearing capacities and material strengths ensure precise calculations. Plus, automatic updates across your project minimizes errors, saving time and maintaining structural integrity.

How Does SolidSteel Offer Innovation and Customization Freedom for Steel Design?

SolidSteel parametric allows designers to create visually striking designs using custom metal profiles. This flexibility is ideal for high-end projects looking for unique elements. Innovate with things like cantilevered staircases and modern railings without traditional constraints, ensuring structural integrity while producing beautiful, distinctive systems that enhance any space.

How Does SolidSteel Parametric Support Collaboration?

Successful stair and railing design requires collaboration among architects, engineers, fabricators, and contractors. SolidSteel parametric, as a mechanical engineering CAD steelwork solution, integrates seamlessly with SOLIDWORKS, enabling unified teamwork. With a shared model, communication is streamlined, changes are swift, and errors are minimized.

Did you know? Within the extended Klietsch software portfolio, the DSTV Assistant can quickly and easily generate your NC files. It integrates seamlessly with manufacturing machines through its NC data module, allowing for smooth communication in the DSTV format.

Conclusion

SolidSteel parametric stands out as a comprehensive steel design solution, empowering engineers and designers to create complex and visually striking stair and railing systems. By simplifying the design of different connections, such as clip angle connections and end plates, SolidSteel ensures that all typical steel connections are secure and compliant. Bolt assistant streamlines the creation of complete bolt sets and cope cuts while supporting standard HV bolt sets.

With tools like the assembly manager, professionals can efficiently manage entire assemblies, ensuring that connected beams and gusset plates are installed with precision. SolidSteel parametric’s intuitive default settings and its ability to handle both custom and standard boreholes make it an invaluable asset for any project. Whether you’re designing simple staircases or intricate modern railings, SolidSteel parametric offers the precision and flexibility needed to bring your vision to life while minimizing errors. Elevate your steelwork designs today by leveraging SolidSteel’s powerful tools for assembly management and customization.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: