Is your SOLIDWORKS Visualize render not realistic enough?

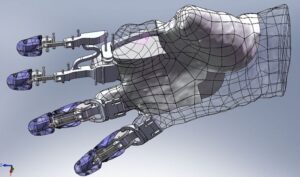

After weeks of design, engineering, and modeling in SOLIDWORKS Visualize, your project is finally ready to present. It is time to share and communicate your concept with others.

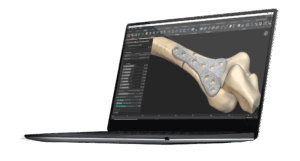

You import your model into SOLIDWORKS Visualize to generate attractive images, but the result lacks realism.

Why is your final render in Visualize not meeting expectations? This article explores common issues, practical solutions, and advanced techniques, including the use of PBR materials, to help you create photorealistic renders in SOLIDWORKS Visualize.

Factors That Can Undermine Realism in SOLIDWORKS Visualize

Several elements can affect the quality of your renders in SOLIDWORKS Visualize. Here are some of the most common:

Is your scene lighting underwhelming in SOLIDWORKS Visualize?

Lighting is a critical factor in SOLIDWORKS Visualize. Using the default lighting imported from SOLIDWORKS may limit your scene’s visual potential. Creating custom lighting directly in Visualize is often the better option, as it gives you greater control over shadows, diffusion, and reflections.

Is the model not detailed enough?

Some modeling features may not be necessary for manufacturing in SOLIDWORKS, but they can be essential for photorealistic rendering. Sharp edges, chamfers, and fine surface details can significantly enhance the visual richness once imported into Visualize.

Is your scene composition lacking?

Scene layout, camera angle, and framing have a major influence on the quality of your render. Use photography principles such as the rule of thirds and depth of field. Adjust your camera settings in SOLIDWORKS Visualize to enhance the visual impact.

PBR Materials: The Key to Realism in SOLIDWORKS Visualize

If your render still seems flat even after optimizing lighting, modeling, and composition, it is time to focus on materials.

Since 2024, SOLIDWORKS Visualize has supported PBR (Physically Based Rendering) materials. These are widely used in professional rendering engines because of their ability to mimic realistic material behaviors.

Benefits of Using PBR Materials in SOLIDWORKS Visualize

-

Flexible parameters: PBR materials make it easy to modify the appearance of a surface. You can switch from metal to plastic just by adjusting a few settings. Often, you can reuse textures to generate entirely different-looking materials.

-

Consistent results: PBR materials provide dependable, realistic results across different lighting and environmental conditions. When configured properly, they behave accurately whether used in indoor or outdoor scenes with artificial or natural lighting.

-

Standardized methods: You do not need to start from scratch. PBR materials follow standardized formats, making them compatible with many 3D software applications. Because they are widely adopted, it is easy to find textures that work with them.

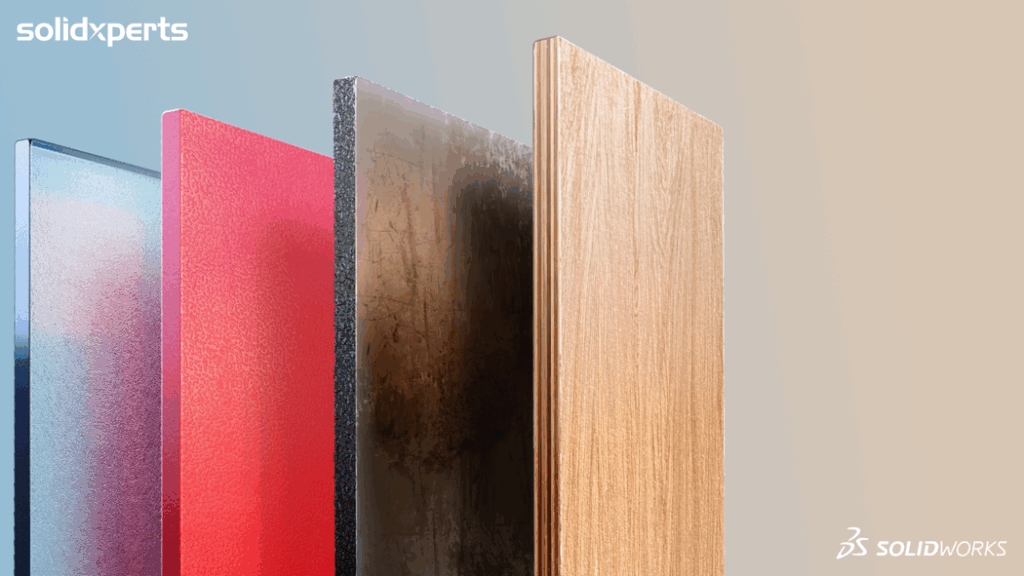

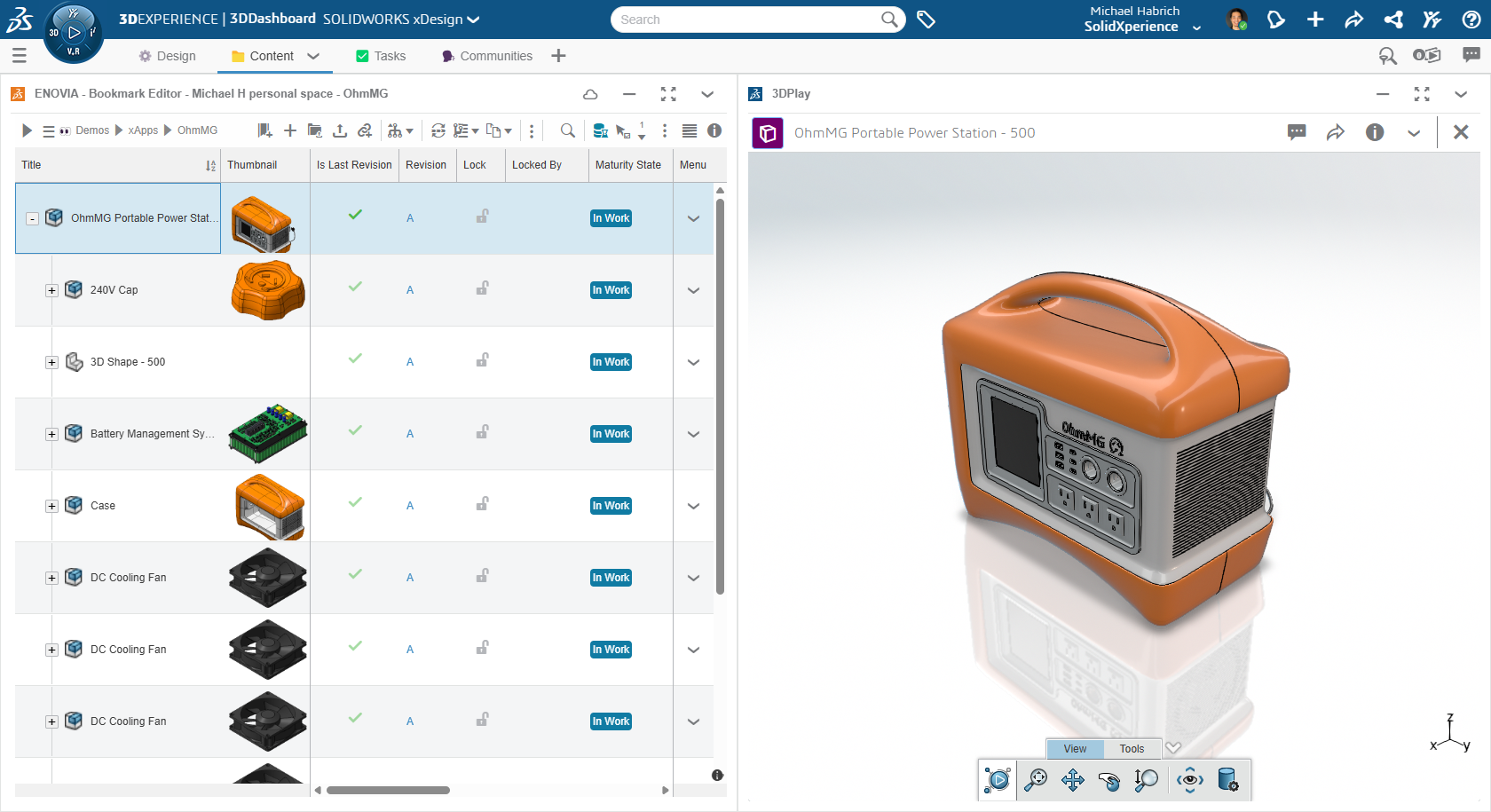

As shown above, PBR materials allow you to generate all kinds of substances, such as wood, metal, plastic, glass, and more. There’s no need to constantly switch material types—just a few parameter changes are enough.

Materials vs. Textures: What’s the Difference?

New users of PBR materials often wonder why more than one texture is needed to create a single material. A photo of wood texture alone is not enough to tell rendering software how the material should behave.

For something as basic as a wood material, you will likely need at least two or three textures to achieve a realistic result. The good news is that you do not have to create these textures yourself. Many PBR texture packs are available online. These texture sets are designed to be layered over your model to produce the desired effect.

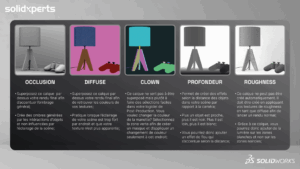

Often, texture packs include more textures than you will actually need in SOLIDWORKS Visualize. That is because each rendering engine may use a different number of texture maps to achieve the same result. In Visualize, you can often create realistic materials using just Diffuse and Roughness textures.

It is important to use stackable textures (from the same family or originating from the same substance) so that the different types of information they generate remain consistent with one another.

My PBR Materials Don’t Look Right…

Now that you are using PBR materials, how do you make sure they stand out? Sometimes the materials are correctly set up, but the lighting, model, or scene fails to showcase their strengths.

It is not enough to configure PBR materials properly. Your rendering environment also needs to support and highlight their details. This is where post-processing becomes essential.

Don’t Expect Final Results in the Viewport!

Do not worry if the real-time preview in the SOLIDWORKS Visualize viewport does not look perfect. Like all rendering engines, Visualize depends on post-processing software such as Photoshop or After Effects to enhance the final image.

In fact, it is normal and often necessary to use post-production tools to bring out the fine details in your render. Visualize cannot generate all the visual information in a single image.

Try Render Passes!

When rendering a scene, the goal is not to get the final result in the viewport. Instead, the objective is to load your scene with as much visual data as possible through materials, textures, lighting, and more.

All of this data cannot be shown effectively in a single image. This is why render passes exist.

This is not an issue unique to SOLIDWORKS Visualize. Most rendering engines cannot produce one image that contains everything you need. Render passes divide your render into multiple images, each representing a different visual component of the scene.

PBR materials become especially useful in this process, as they contain more embedded data. This extra information is saved in the render passes and can be layered in post-production software to fine-tune your image.

On the left, the raw render as produced in Visualize without using render passes. On the right, the same render, procedurally enhanced in Photoshop by applying the different layers generated by SOLIDWORKS Visualize.

Choose a Procedural Post-Production Workflow

Post-production software like Photoshop can be complex to learn. That’s why you should adopt a procedural workflow that relies not on your team’s artistic skills, but on predefined parameters.

When incorporating your render passes into your post-production software, avoid editing the image using brushes or other destructive methods. Instead, use layer blending and masks to follow a workflow that delivers consistent results. This approach is not only easy to adjust, but also easy to teach to the rest of your team.

There’s no need to draw, paint, or create special effects—your render layers already contain all the information you need to produce a final image that matches your vision (see image below).

It’s Now your Turn to Make Your SOLIDWORKS Visualize Renders Stand Out!

Your project deserves to shine in SOLIDWORKS Visualize. By applying modeling best practices, using the power of PBR materials, and enhancing your images through post-production, you are now equipped to create renders that effectively communicate your design vision.

With some experience, you will be able to showcase every visual detail and deliver final images that are clear, realistic, and impactful.

If you have more questions, our SOLIDWORKS Visualize experts are here to support you in optimizing your rendering process.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: