A few weeks ago, my SOLIDWORKS Elite Applications Engineer award fell, and the top part of it broke. I was both sad and frustrated. Sad because it meant something to me, and frustrated because I had placed it on a shelf that later tilted unexpectedly, sending everything crashing to the floor. Finding it broken on the ground that day was tough.

Accidents like this happen all the time. The products we design are also at risk of being dropped, so why not make them as resistant as possible?

That’s exactly where SOLIDWORKS Simulation drop tests come in.

In this guide, you’ll learn:

- what a drop test is,

- why drop test analysis is essential for product reliability,

- and how to run a drop test in SOLIDWORKS Simulation step by step.

Why Drop Tests Matter for Product Design?

Any time a product is handled, shipped, carried, or installed, there’s a chance it could be dropped. A single impact can compromise safety, durability, performance, and sometimes even a company’s reputation.

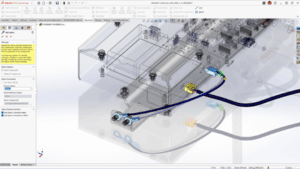

Drop tests help engineers predict how their products will behave in real-world accident scenarios. Below are examples of industries where drop testing is essential to ensure reliability before manufacturing:

- Consumer products & electronics

- Industrial & heavy equipment

- Medical devices

- Sports equipment

- Aerospace & aviation

- Automotive & transportation

- Military & defense

- Packaging & logistics

- Robotics & automation

- Construction & civil engineering

Drop Test Prerequisites: What You Need Before Running a Simulation

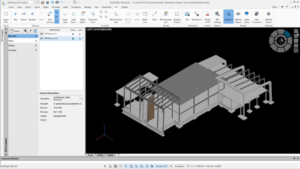

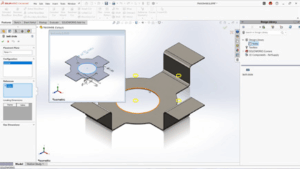

Before running a drop test analysis, certain elements must be prepared. A 3D design is required to simulate the event digitally. Here are the steps:

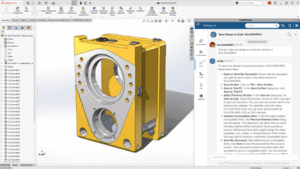

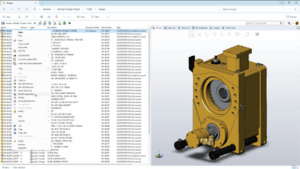

- Create the 3D model in SOLIDWORKS or import an existing geometry.

- Apply materials (this step can also be performed directly in the study).

- Simplify the model to reduce solving time (this may include suppressing non-critical parts or features).

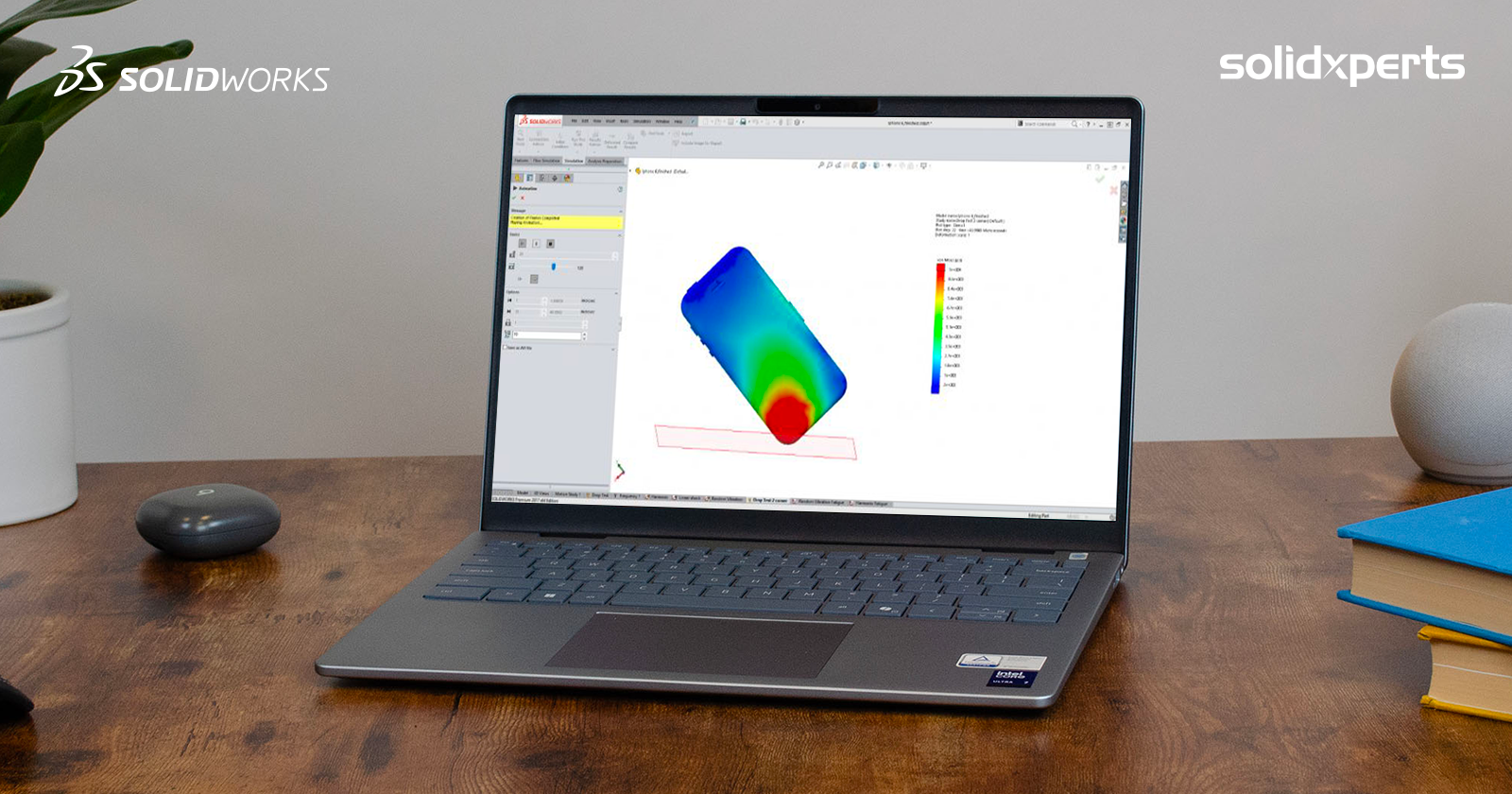

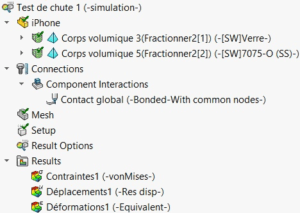

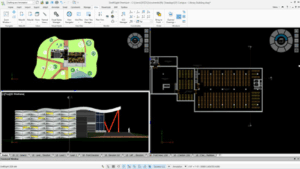

How to Run a Drop Test Analysis in SOLIDWORKS Simulation

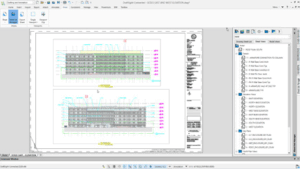

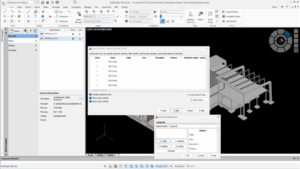

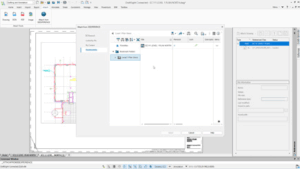

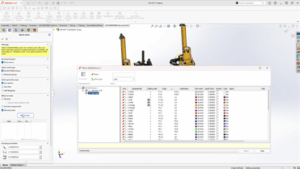

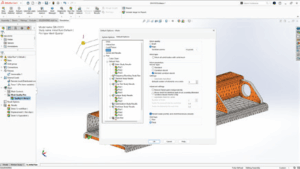

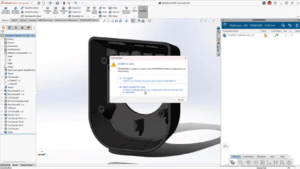

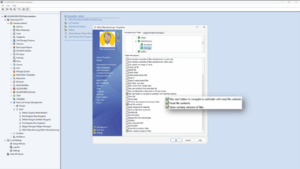

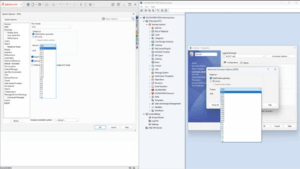

Once your model is ready, you can set up the drop test using the following steps:

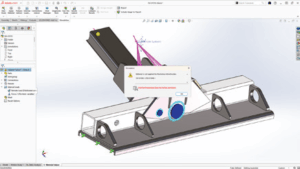

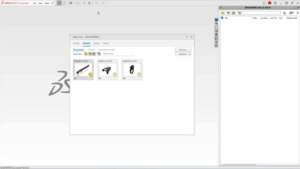

- Enable the SOLIDWORKS Simulation add-in.

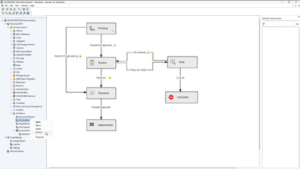

- Create a new Drop Test study.

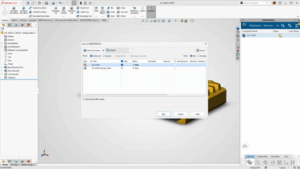

- Apply any missing material properties.

- Define interactions if needed.

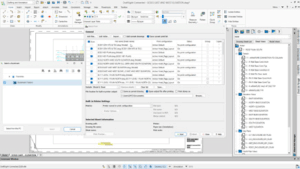

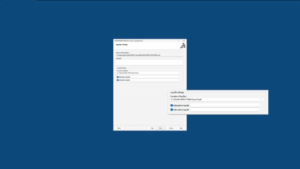

- Set up the drop test conditions (drop height or impact velocity, orientation, ground parameters, etc.).

- Adjust result options (duration after impact, saving options, etc.).

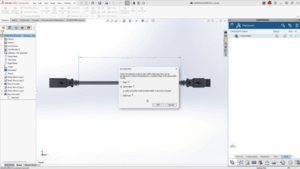

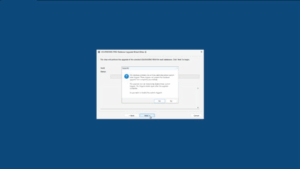

- Mesh the model and run the analysis.

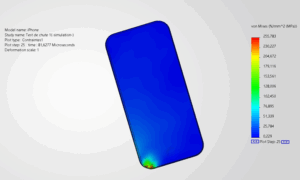

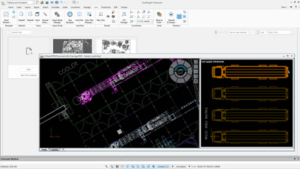

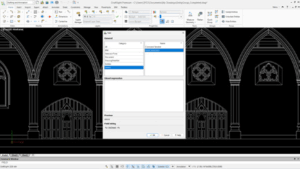

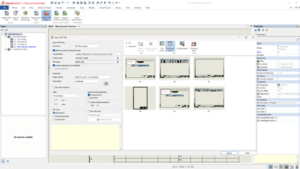

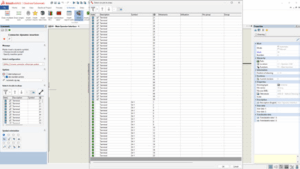

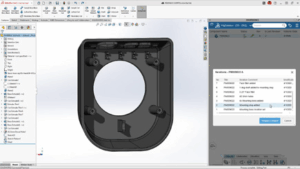

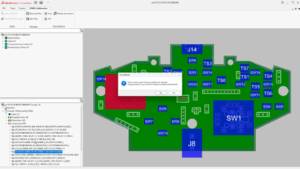

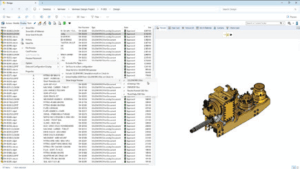

Interpreting Your Drop Test Results

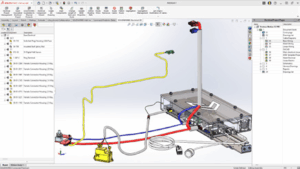

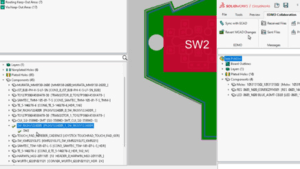

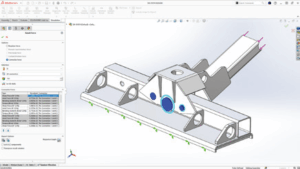

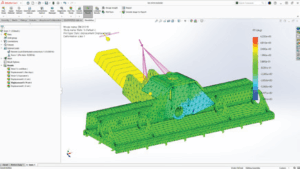

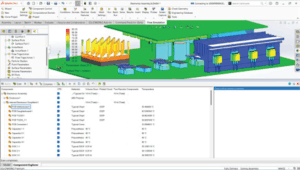

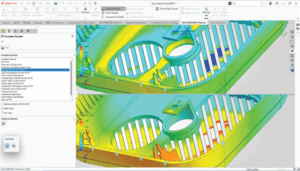

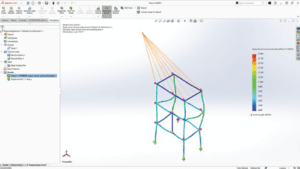

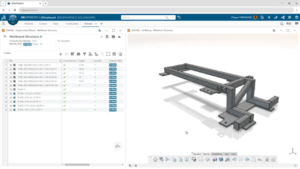

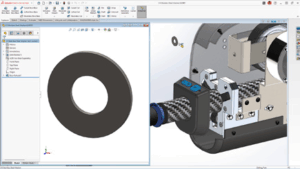

After running the analysis, several result types become available, such as stress and deformation plots. These help you determine whether the product will remain elastic, undergo plastic deformation, or potentially fail, and where such failures are likely to occur.

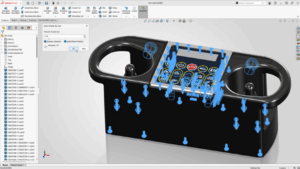

The example below shows the kind of output SOLIDWORKS Simulation provides once the calculations are complete:

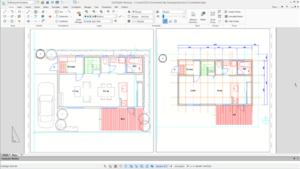

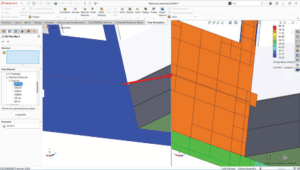

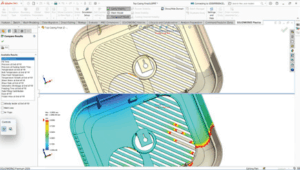

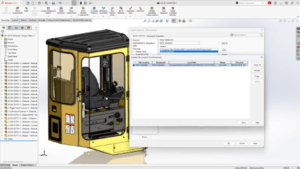

Improving the Design Through Simulation

Thanks to the results, you can identify weak points where the product is likely to fail. You can then reinforce the design. For example, by adding fillets, increasing wall thickness, or selecting a stronger material.

Sometimes, results show that a part is overdesigned. In these cases, you may reduce thickness or remove unnecessary material to lower weight and cost. This is a key step in optimizing your product.

Simply make the changes and re-run the drop test to validate the improvements.

Bringing It All Together: Stronger Designs Through Simulation

With SOLIDWORKS Simulation, you can test your product digitally long before manufacturing it. A drop test is just one of many analysis types available to help you validate performance and reliability.

I initially blamed myself for the broken award, but maybe if the shelf had been designed to be stronger, the accident could have been avoided. Who knows?

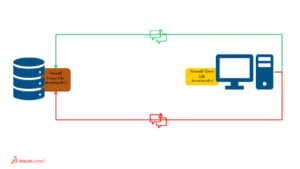

From linear static to nonlinear dynamic analyses, SOLIDWORKS Simulation provides a complete suite of tools to help engineers validate their designs efficiently. At Solidxperts, we are committed to helping our customers achieve excellence in their engineering projects.

Looking to sharpen your skills? Browse our upcoming trainings, available at our offices or online. Whether you’re new to simulation or ready to deepen your expertise, our certified specialists are here to support you every step of the way.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: