3D scanning technology has become increasingly accessible and versatile, allowing professionals to capture accurate digital models of objects in nearly any environment. Whether you’re scanning indoors in a controlled space or outdoors in unpredictable conditions, understanding how your tools respond to these settings is key. To better illustrate this distinction, the Artec Ray and Artec Leo are two scanners designed for different strengths the Ray excels at long-range, high-accuracy scanning, while the Leo offers handheld mobility and real-time feedback. As a result, when paired together or used separately, they can tackle a wide variety of scanning tasks with the right preparation.

How to Optimize Outdoor 3D Scans with the Artec Leo Handheld Scanner

The Artec Leo is a versatile handheld 3D scanner that can handle a wide range of outdoor scanning tasks, including vehicles and textured objects like statues. While it may require additional preparation for reflective surfaces, its mobility and real-time feedback make it a powerful tool for capturing complex shapes. To support this, here are some of the Leo’s key technical capabilities:

· 3D point accuracy: Up to 0.1 mm

· Scanning range: 0.4 to 10 meters

· 3D resolution: Up to 0.2 mm

· 3D reconstruction rate: Up to 80 frames per second (FPS)

· Volume capture zone: 160,000 cm³

· Display: Built-in touchscreen panel

· Processing: Onboard real-time 3D data processing

Moreover, by understanding these capabilities and adapting the scanning approach like adding reference points on reflective surfaces you can optimize results whether scanning vehicles or textured statues.

Improving Scan Accuracy with Reference Points and Cleanup Tools

When working on larger projects, scan data can quickly become overwhelming. Especially when imported into Artec Studio. Often, the scans initially appear as a chaotic mess, with no clear orientation. For instance, a great example is our practice scan of a truck using the Artec Leo. This scan was done in peak sunlight, which made the truck’s reflective sides more difficult to capture accurately. To help with alignment, we placed small magnets on the sides of the truck as reference points. Thanks to Artec Studio’s user-friendly cleanup tools, the process of aligning parts becomes much smoother, reducing both time and stress. This practice emphasizes the importance of capturing high-quality and thorough scans from the start. Taking a bit more care during scanning can significantly speed up post-processing, making it easier for both you and your computer.

When to Use the Artec Ray for Outdoor Scanning

The Artec Ray 3D scanner excels in outdoor scanning projects that demand precision over large areas. Its metrology-grade accuracy and long-range capabilities make it ideal for capturing detailed scans of buildings, infrastructure, and large objects. Key technical specifications include:

- 3D point accuracy:

- 1.9 mm at 10 meters

- 2.9 mm at 20 meters

- 5.3 mm at 40 meters

- Angular accuracy: 0.87 mm at 10 meters (18 arcseconds)

- Range accuracy: 1.0 mm + 10 ppm

- Range noise: 0.4 mm at 10 meters, 0.5 mm at 20 meters

While outdoor conditions such as bright sunlight or uneven terrain may pose challenges, using a stable tripod and scanning during optimal lighting can help ensure the Ray produces highly detailed and reliable scans with minimal post-processing.

Using Artec Leo and Ray for Advanced Outdoor 3D Scanning Workflows

When working outdoors, leveraging both the Artec Leo and Artec Ray 3D scanners allows for a more versatile and efficient scanning process. The Ray handles broad, large-scale captures, creating a detailed foundation that ensures no major features are missed. Meanwhile, the Leo excels at filling in smaller or more complex areas that require flexibility and maneuverability. By integrating data from both devices, you can achieve a highly detailed and complete 3D model. Planning your scanning sequence thoughtfully starting with the Ray and following up with the Leo streamlines data alignment and reduces overall processing time making the workflow smoother and more productive.

Why the Artec Leo Excels in Small and Complex Indoor Spaces

Indoors, the Artec Leo’s handheld design and real-time processing offer significant advantages for scanning smaller spaces or detailed objects. In addition, its portability allows operators to move easily around furniture, fixtures, or machinery, capturing intricate details that stationary scanners might miss. Additionally, the built-in touchscreen and immediate feedback help ensure scan quality on the spot, reducing the need for reshoots. This makes the Leo especially useful for tasks like heritage preservation, quality control, and product design within confined or complex indoor environments.

Real-World Scan: Digitizing a Trade Show Display with Artec Leo

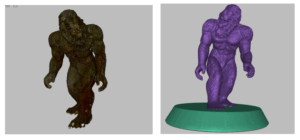

During our last trade show, there was a vendor Gorilla Circuits that had a fun Sasquatch podium piece which they allowed us to scan with the Leo so we could demonstrate just how easy it is to take an object and digitize it using the Artec Leo process. The scan data was then 3D printed on the Raise3D Pro3 and the Markforged Mark Two Desktop 3D Printer.

In fact, it really only took one primary scan and two small scans to fill in the missing information. Artec Fusion software was able to fill in any missing sections with extreme accuracy, referencing the scan data to create a watertight file. The original Sasquatch was just under two meters tall, and the 3D printed models were 180 mm tall for the display case.

Why the Artec Ray Is Ideal for Large Indoor Environments

The Artec Ray is well suited for mapping large indoor environments such as production floors, warehouses, or empty buildings. Similarly, its long-range scanning capability allows for fast and accurate capture of expansive areas, which is essential for planning HVAC installations, scaffolding setups, or construction projects. By providing precise spatial data from floor to ceiling, the Ray helps engineers and architects create reliable models to support design and implementation. The scanner’s stability and accuracy reduce the time spent on manual measurements, streamlining workflows in large-scale indoor projects.

From Insight to Action: Match the Scanner to the Job

Ultimately, whether you are scanning a compact object in a cluttered room or mapping out an entire facility, knowing how to get the most out of your equipment is key. The Artec Leo and Ray each bring unique strengths to the table, and when used together, they can cover nearly every scanning scenario both inside and out. Success comes from understanding your environment, choosing the right tool for the job, and preparing your scan area thoughtfully.

If you’re ready to take the next step, contact us for full access to product demos, hands-on training, and expert guidance to help you get started with confidence.