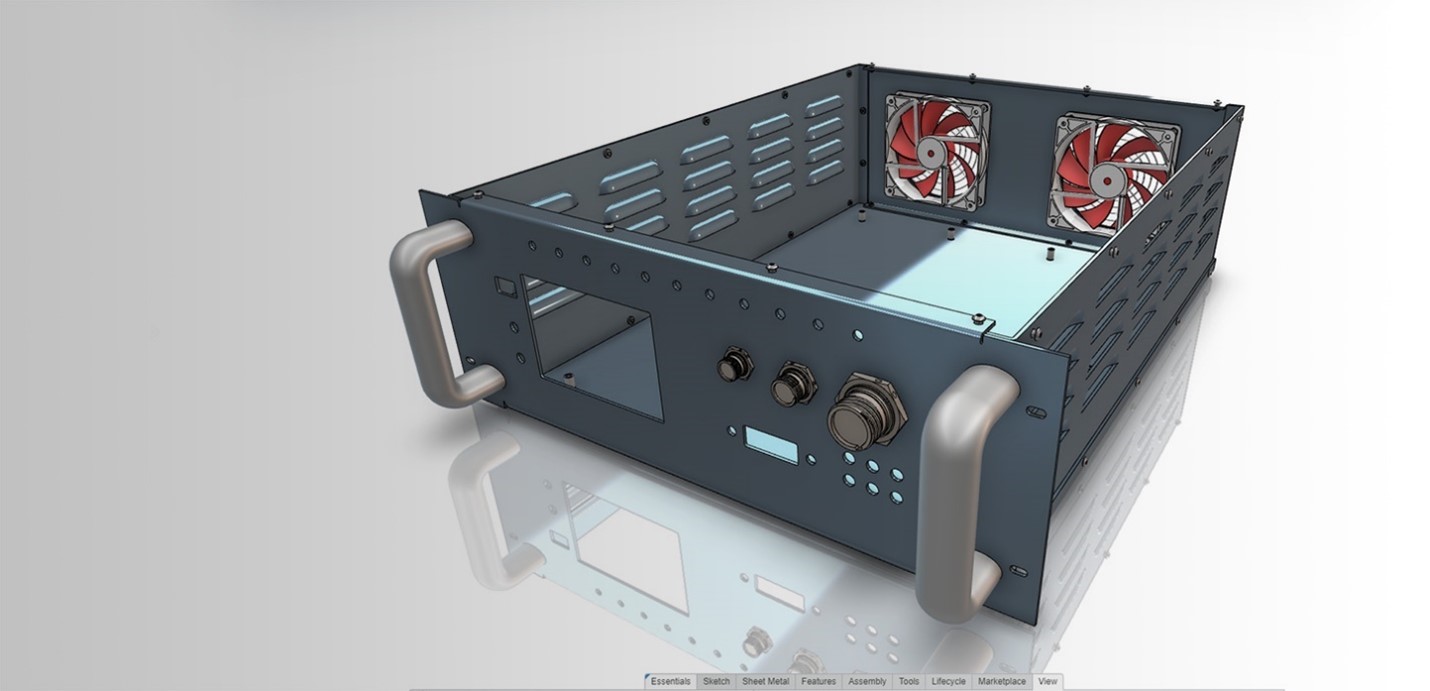

SOLIDWORKS PDM 2025 delivers a range of improvements designed to enhance usability, security, and efficiency across engineering and manufacturing workflows. From improved Bill of Materials (BOM) visualization to increased flexibility for caching data, this update makes it easier than ever to manage design files, collaborate across teams, and maintain version control.

New features like a redesigned user interface for better accessibility, improved web performance, and expanded user tracking help streamline everyday operations while ensuring greater control and security. Whether you’re managing thousands of files, working remotely, or overseeing large engineering projects, SOLIDWORKS PDM 2025 delivers powerful upgrades to keep your team productive.

Introduction

Managing product data efficiently is essential for engineering, design, and manufacturing teams. SOLIDWORKS PDM (Product Data Management) is the backbone of collaborative design workflows, ensuring that teams can securely store, track, and manage design data across projects. With SOLIDWORKS PDM 2025, users can expect improved usability, better security, and enhanced performance, making it easier and faster than ever to access, update, and share CAD files. Let’s explore the latest enhancements in SOLIDWORKS PDM 2025 and how they can boost productivity and collaboration.

This blog will break down the latest enhancements—what’s new, why it matters, and how SOLIDWORKS 2025 can optimize your data management workflows.

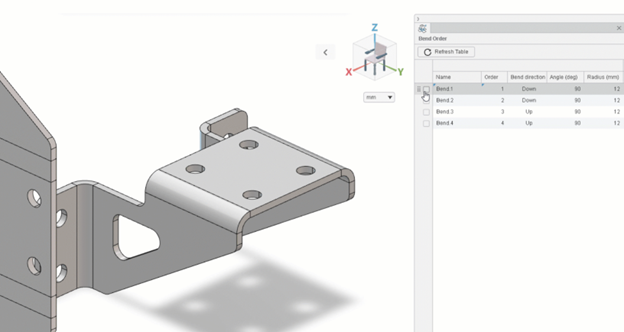

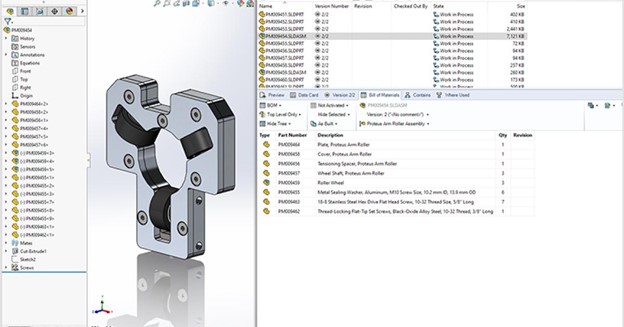

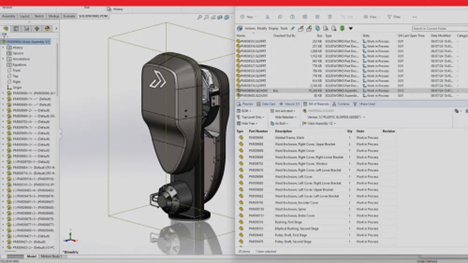

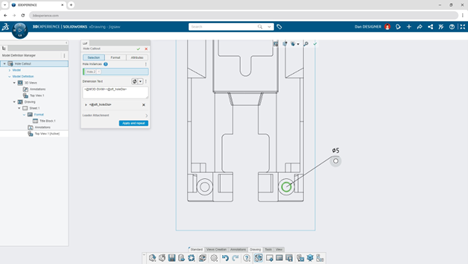

Improved Bill of Materials Visualization: Easier to Read, Easier to Manage

Understanding assembly structures is crucial for managing complex product designs. SOLIDWORKS PDM 2025 introduces an improved Bill of Materials (BOM) visualization, making it easier to interpret and navigate component relationships.

What’s New

- BOM structure now matches the order of the SOLIDWORKS FeatureManager

- Clearer visualization of part hierarchies within assemblies

- Easier tracking of materials, components, and configurations

Why It Matters

For engineers and manufacturers, a well-structured BOM is key to ensuring accurate production and assembly planning. With a more intuitive layout, teams can quickly verify part dependencies, detect errors, and optimize inventory management.

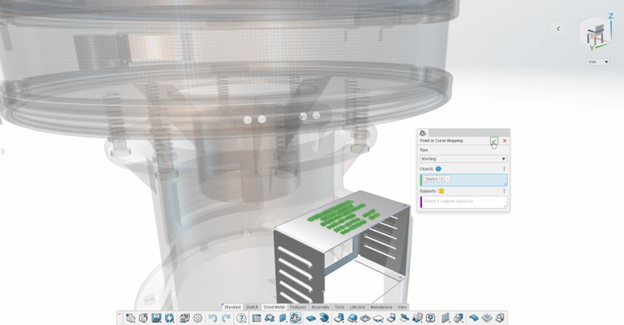

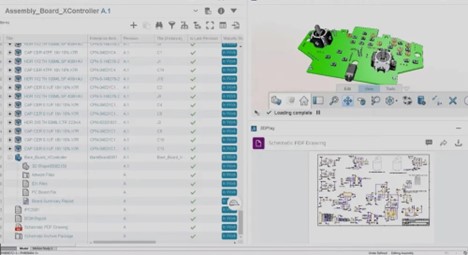

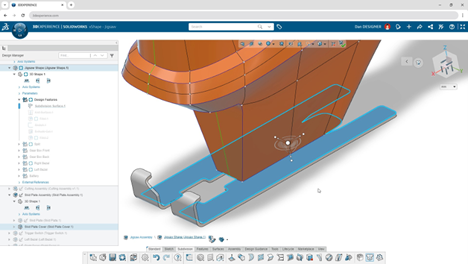

Increased Flexibility for Caching Data: Faster Access, Less Hassle

Accessing large datasets can be slow, but SOLIDWORKS PDM 2025 now gives users more control over how data is cached. New options allow for faster retrieval of files, ensuring smoother performance when working with large assemblies.

What’s New

- Check out files directly from the “Get Latest” dialog

- Choose whether to cache the latest revision or a specified version

- Optimize storage space and access speed based on project needs

Why It Matters

With greater control over caching settings, users can reduce unnecessary data transfers, speed up loading times, and minimize server load. This is especially beneficial for remote teams and multi-site collaborations.

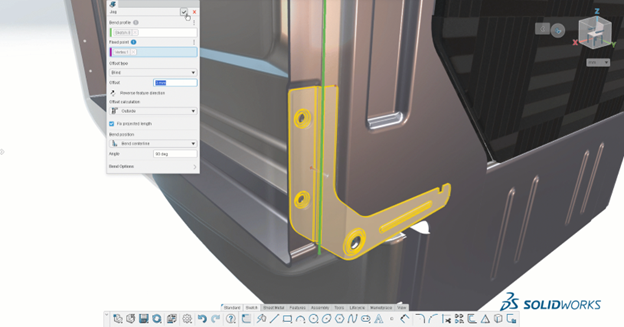

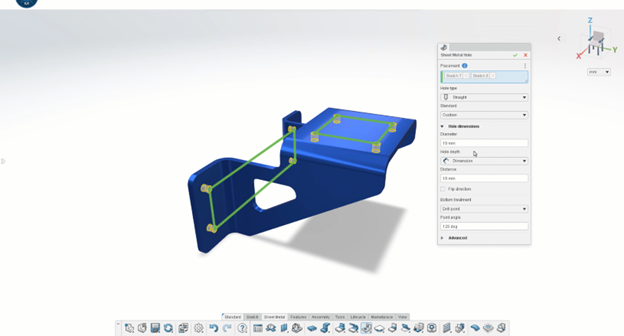

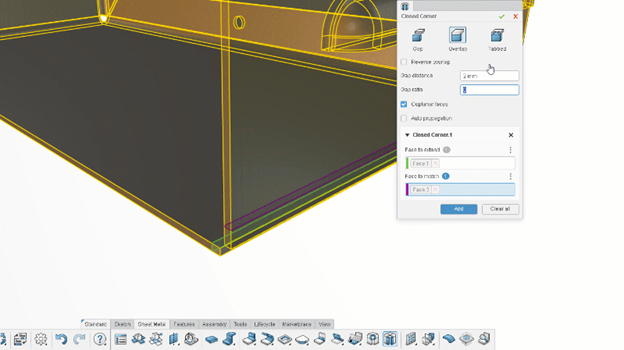

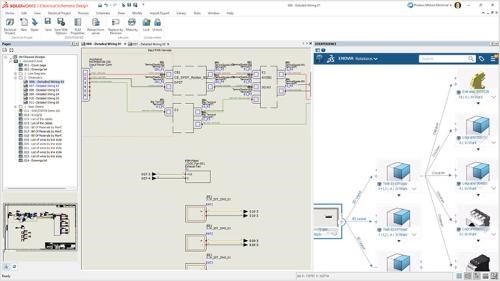

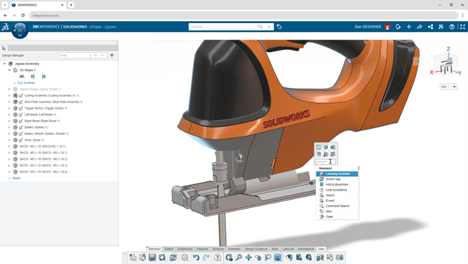

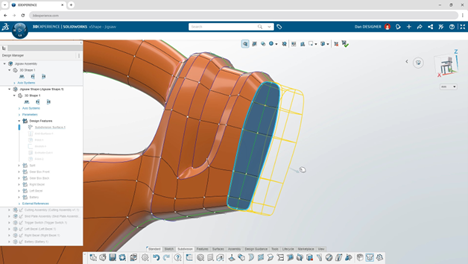

Better User Experience: A More Intuitive Interface

Navigating SOLIDWORKS PDM is now easier than ever, thanks to UI enhancements that prioritize usability and workflow efficiency.

What’s New

- New SOLIDWORKS PDM tab added to the CommandManager toolbar

- Access PDM functions without needing the Task Pane

- Larger graphics area for an improved design experience

Why It Matters

These improvements allow users to focus more on their design work without constantly switching between windows or navigating through multiple clicks. By simplifying access to key commands, SOLIDWORKS PDM 2025 enhances productivity and reduces workflow interruptions.

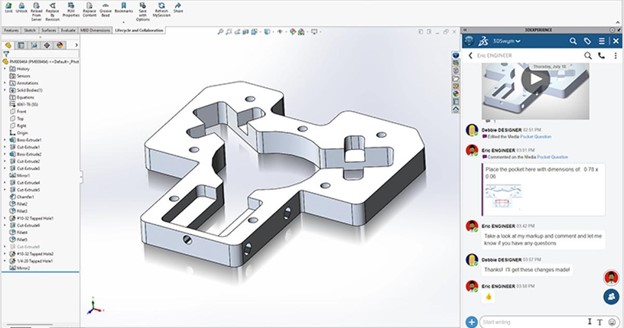

Increased User Tracking: Stronger Security and Compliance

Security and compliance remain top priorities, and SOLIDWORKS PDM 2025 introduces expanded user tracking features.

What’s New

- Tracks user logins and logouts for better audit trails

- More comprehensive record-keeping for compliance and security

- Easier identification of who accessed, modified, or approved files

Why It Matters

With enhanced tracking and security measures, businesses can better protect sensitive data, ensure compliance with regulatory standards, and maintain a reliable history of design changes. This is particularly valuable for industries with strict documentation requirements, such as aerospace, medical devices, and automotive manufacturing.

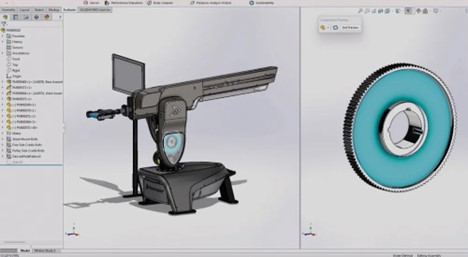

Improved Web 2.0 Performance: Faster, More Flexible Web Access

For teams using the SOLIDWORKS PDM web client, performance and accessibility have been greatly improved in 2025. These updates provide faster browsing speeds, improved file previews, and a smoother user experience.

What’s New

- Browse large folders faster, even with thousands of files

- Improved file preview performance for quicker document review

- Greater flexibility when accessing PDM from a web-based interface

Why It Matters

For users who work remotely or need quick access to design data without a full PDM installation, these web performance improvements ensure seamless access and responsiveness. The ability to navigate large datasets efficiently saves time and enhances overall productivity.

Why Choose SOLIDWORKS PDM 2025?

SOLIDWORKS PDM 2025 isn’t just about managing files—it’s about creating a more connected, efficient, and secure engineering workflow. Having the files and information you need, when and where you need them. Whether you’re a small design team or a global enterprise, these improvements help ensure that your data is always accessible, protected, and optimized for collaboration.

- More Efficient BOM Management – Improved visualization for easier part tracking and assembly planning.

- Faster File Retrieval – Increased caching flexibility ensures quick access to revisions and large datasets.

- Streamlined User Interface – A redesigned UI and new CommandManager integration make working in PDM more intuitive.

- Enhanced Security & Audit Trails – Track user logins, logouts, and file modifications for improved oversight.

- Better Web Access – Experience faster performance and more responsive browsing in the PDM web client.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

Marc Raibert, a lifelong roboticist, has been at the forefront of robotics innovation for over 50 years. As the founder of Boston Dynamics, he led the creation of iconic robots like BigDog, Atlas, and Spot, which revolutionized dynamic mobility. He founded The AI Institute in 2022 to advance intelligent robotics. Raibert’s career highlights include tenure at MIT and Carnegie Mellon University, pioneering dynamic robot research at the Leg Laboratory, and earning accolades like the IEEE Robotics Pioneer Award and the Engelberger Award. His inspiring journey continues to shape the future of robotics and AI.

Marc Raibert, a lifelong roboticist, has been at the forefront of robotics innovation for over 50 years. As the founder of Boston Dynamics, he led the creation of iconic robots like BigDog, Atlas, and Spot, which revolutionized dynamic mobility. He founded The AI Institute in 2022 to advance intelligent robotics. Raibert’s career highlights include tenure at MIT and Carnegie Mellon University, pioneering dynamic robot research at the Leg Laboratory, and earning accolades like the IEEE Robotics Pioneer Award and the Engelberger Award. His inspiring journey continues to shape the future of robotics and AI.

Spot, the versatile robotic platform, will make a special appearance at 3DEXPERIENCE World 2025. Known for its dynamic mobility and adaptability, Spot has garnered fame for its ability to navigate diverse environments, carry payloads, and even climb stairs with ease. This particular Spot, nicknamed “One”, has achieved celebrity status, starring in a Billie Eilish music video and even making an appearance in renowned sci-fi franchise, Black Mirror. Don’t miss the chance to see Spot live in action!

Spot, the versatile robotic platform, will make a special appearance at 3DEXPERIENCE World 2025. Known for its dynamic mobility and adaptability, Spot has garnered fame for its ability to navigate diverse environments, carry payloads, and even climb stairs with ease. This particular Spot, nicknamed “One”, has achieved celebrity status, starring in a Billie Eilish music video and even making an appearance in renowned sci-fi franchise, Black Mirror. Don’t miss the chance to see Spot live in action! Gian Paolo Bassi – With over 25 years in the 3D, CAD, and PLM industries, Gian Paolo Bassi drives innovation as 3DEXPERIENCE Works SVP & Customer Role Experience. Previously SOLIDWORKS CEO, he spearheaded groundbreaking developments in cloud-based design. Before Dassault Systèmes, he founded RIWEBB and co-invented multiple patents at ImpactXoft, showcasing his passion for advancing functional modeling and collaboration technologies.

Gian Paolo Bassi – With over 25 years in the 3D, CAD, and PLM industries, Gian Paolo Bassi drives innovation as 3DEXPERIENCE Works SVP & Customer Role Experience. Previously SOLIDWORKS CEO, he spearheaded groundbreaking developments in cloud-based design. Before Dassault Systèmes, he founded RIWEBB and co-invented multiple patents at ImpactXoft, showcasing his passion for advancing functional modeling and collaboration technologies. Suchit Jain – Vice President of Strategy & Business Development, Suchit Jain leads the cloud transformation and 3DEXPERIENCE Works expansion of SOLIDWORKS, focusing on product and sales strategies. He also oversees the User Advocacy team, supporting SOLIDWORKS’ passionate global community. A mentor and advocate for startups, Suchit actively engages with innovation hubs like Greentown Labs and MassChallenge, driving collaboration between entrepreneurs and resources. His academic achievements include a bachelor’s degree from IIT Bombay and a master’s degree in Structural Mechanics from USC.

Suchit Jain – Vice President of Strategy & Business Development, Suchit Jain leads the cloud transformation and 3DEXPERIENCE Works expansion of SOLIDWORKS, focusing on product and sales strategies. He also oversees the User Advocacy team, supporting SOLIDWORKS’ passionate global community. A mentor and advocate for startups, Suchit actively engages with innovation hubs like Greentown Labs and MassChallenge, driving collaboration between entrepreneurs and resources. His academic achievements include a bachelor’s degree from IIT Bombay and a master’s degree in Structural Mechanics from USC. Manish Kumar – With over two decades at SOLIDWORKS, Manish Kumar has been instrumental in driving innovation. As CEO, he leads the synergy between R&D and SOLIDWORKS’ vibrant user community, fostering adoption of the expanding SOLIDWORKS portfolio. From pioneering developments in sketching and modeling to introducing V6 technology, Manish has shaped the future of design. A graduate of IIT Delhi and Harvard University, he is also an artist, woodworker, and avid cricket enthusiast, balancing his professional achievements with personal passions.

Manish Kumar – With over two decades at SOLIDWORKS, Manish Kumar has been instrumental in driving innovation. As CEO, he leads the synergy between R&D and SOLIDWORKS’ vibrant user community, fostering adoption of the expanding SOLIDWORKS portfolio. From pioneering developments in sketching and modeling to introducing V6 technology, Manish has shaped the future of design. A graduate of IIT Delhi and Harvard University, he is also an artist, woodworker, and avid cricket enthusiast, balancing his professional achievements with personal passions.