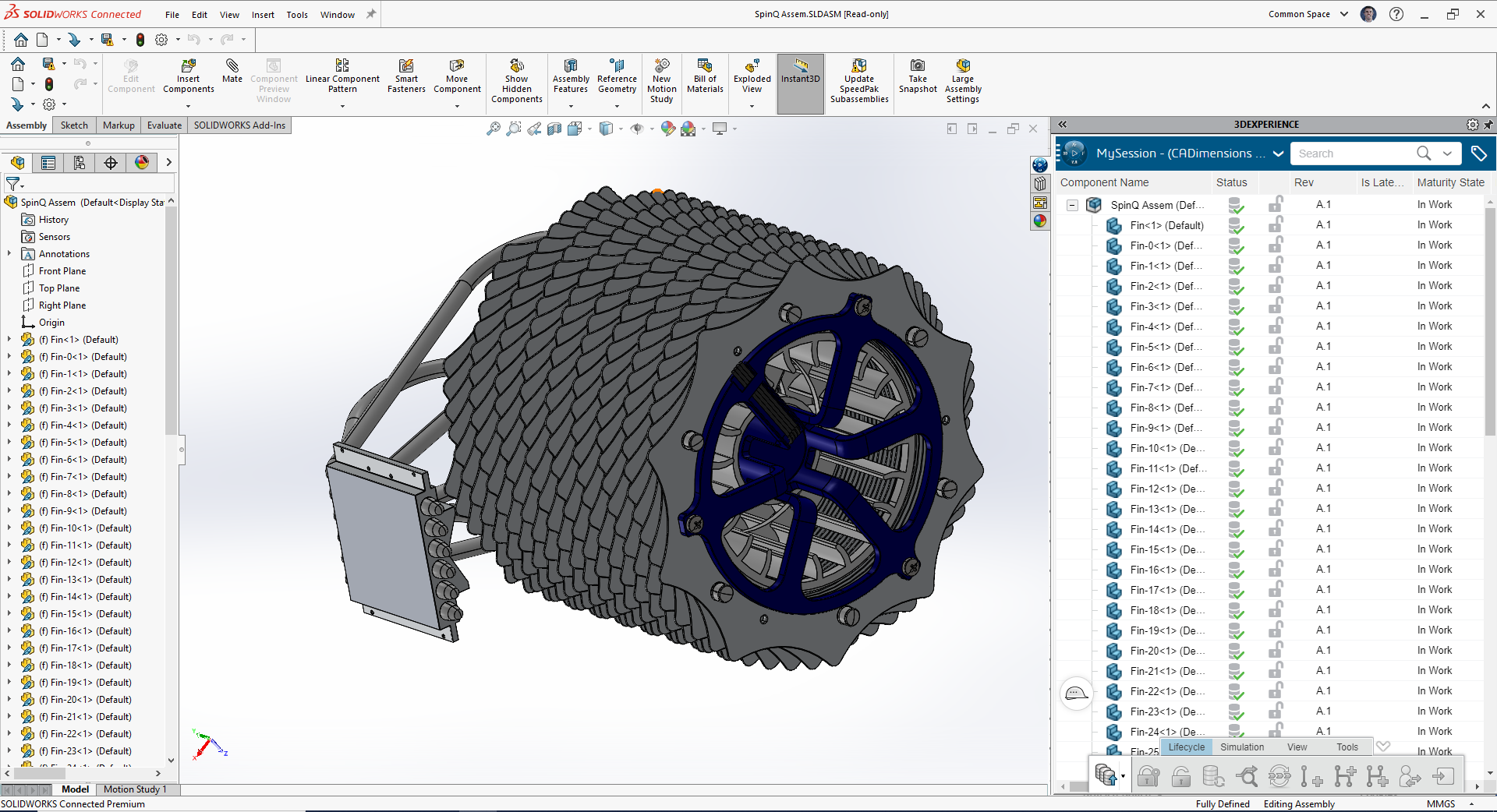

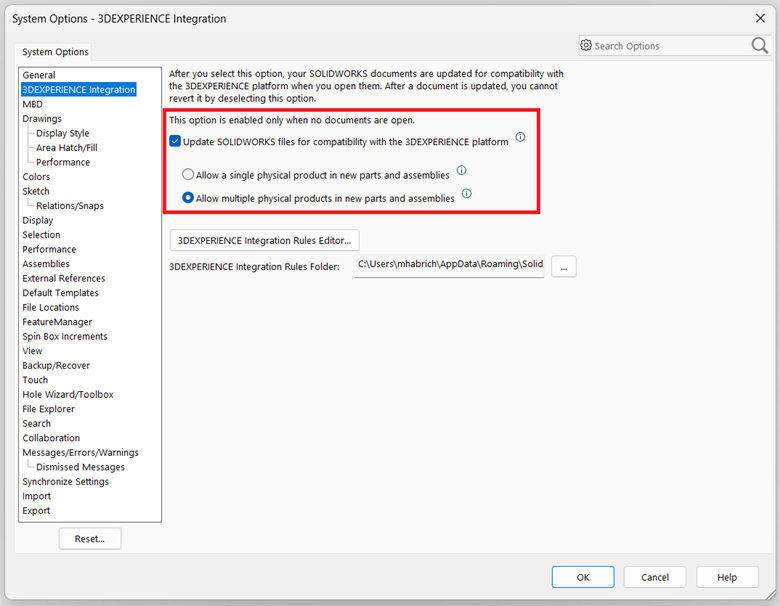

3DEXPERIENCE xApps are cloud-based applications that bring cutting-edge capabilities to your SOLIDWORKS workflow, empowering users to complete projects with greater speed, accuracy, and collaboration. Whether you’re working on sheet metal design, molding, or simulation, these CAD apps are specifically tailored to help you tackle any specific task—and they’re accessible right from your browser.

Purpose-built on the 3DEXPERIENCE platform, these apps expand the functionality of SOLIDWORKS while providing truly browser-based CAD. Whether you’re managing revisions on geometry, performing a draft analysis, or modeling complex enclosures and molds, these apps streamline your processes, ensuring efficiency and clear communication at every stage.

Let’s explore how 3DEXPERIENCE xApps enhance your SOLIDWORKS workflow, with a focus on key benefits and best practices for integrating these powerful tools into your daily design operations.

First, What Are the xApps?

xApps are cloud-based CAD apps that provide you with enhanced sheet metal design, draft analysis, molding, and simulation capabilities. Integrating SOLIDWORKS and the 3DEXPERIENCE platform, these roles and apps enable you to perform specific tasks faster and more effectively.

xApps in the 3DEXPERIENCE platform provide a range of tools to meet various design needs. Below is a quick breakdown of each app and its core functionality:

- xDesign: A flexible CAD tool that enables users to create, modify, and finalize designs directly in their browser, perfect for concept development and detailed modeling.

- xShape: A powerful app focused on subdivision surface modeling, allowing users to craft complex, organic shapes for designs like enclosures and molds with ease.

- xSheetMetal: Tailored for sheet metal design, this app offers intuitive features to create accurate sheet metal components while maintaining associative parametric sheet metal design capabilities.

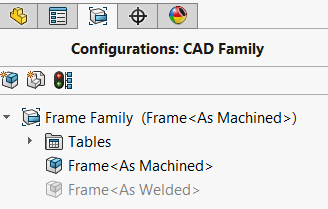

- xFrame: A structural design app that simplifies the creation of welded and bolted frames, making it ideal for projects requiring detailed frame modeling.

- xGenerative Design: An innovative app that leverages simulation and algorithms to automatically generate optimized design solutions based on functional requirements and constraints.

- xMold: Focuses on molding projects, enabling users to design and test injection mold parts with integrated simulation features to validate designs before production.

Each of these apps integrates seamlessly with SOLIDWORKS and the 3DEXPERIENCE platform, allowing users to streamline their workflows across various design stages. For a more detailed look at how to use apps on the platform, check out our previous blog!

Streamline Your SOLIDWORKS CAD Workflows with xApps

xApps provide CAD designers with tools to complete complex tasks, from sheet metal to molding and simulation. By integrating SOLIDWORKS with these apps, you gain access to advanced tools that simplify your workflows and increase productivity.

What Is the Creator Role?

The creator role provides essential tools like xDesign and xShape, which allow designers to create advanced models and sketches. With these apps, designers can manipulate subdivision surfaces and achieve more fluid, organic shapes for enclosures, molds, or sheet metal projects.

Why Should You Use These Apps in Your Browser?

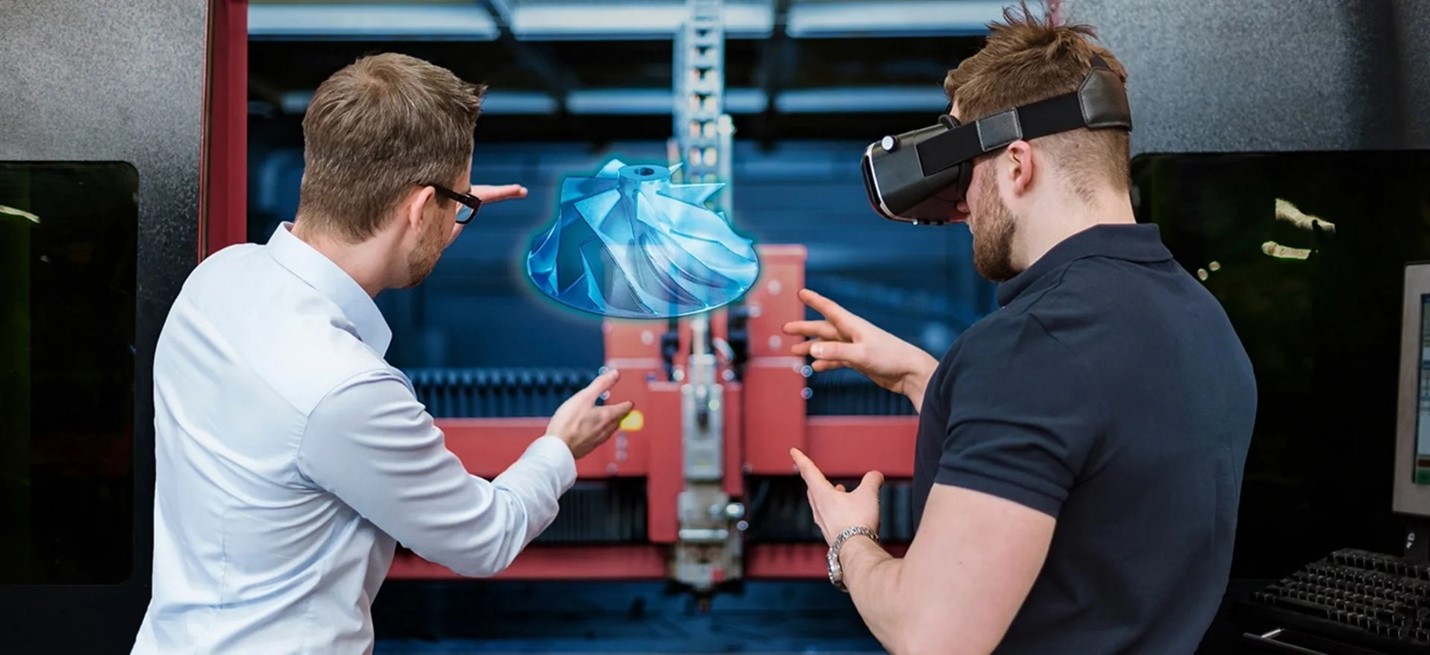

One of the standout features of 3DEXPERIENCE xApps is that they can be accessed directly from your browser. Whether you’re designing sheet metal parts or running simulation tests, you no longer need to install complex software locally. Working in the cloud makes collaboration with other SOLIDWORKS users faster and more efficient.

When using 3DEXPERIENCE xApps, it’s important to follow best practices to ensure efficiency. Whether it’s using the PDM system to manage revisions or employing xDesign for accurate geometry creation, following guidelines ensures you get the most out of the tools available.

Quick-Start Guide to 3DEXPERIENCE xApps

Getting started with xApps is simple. This quick-start guide provides guidance for SOLIDWORKS users to begin integrating these apps into their daily workflows, ensuring you’re ready to tackle any specific task with ease.

Using xApps for Molding and Simulation

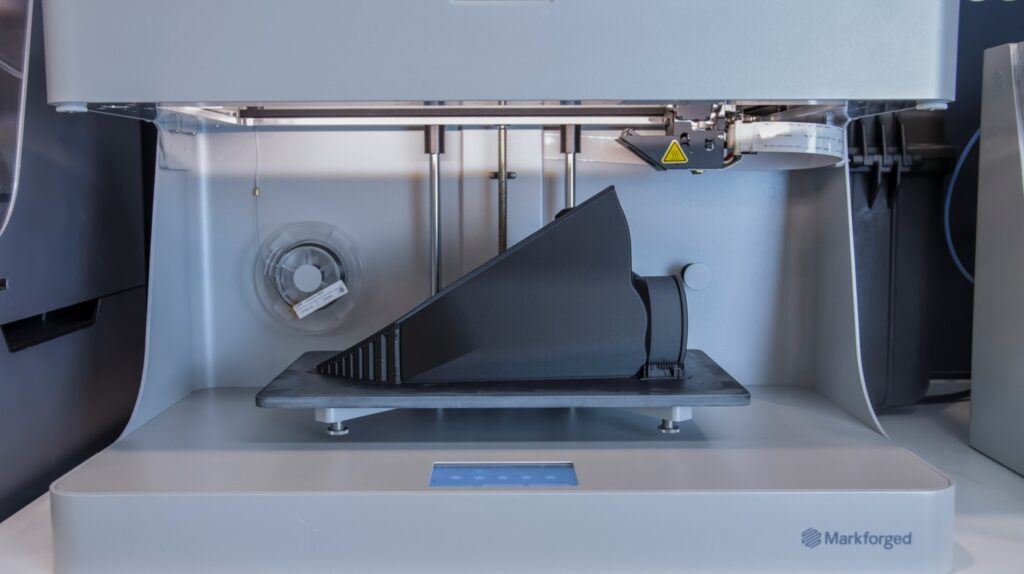

The 3DEXPERIENCE platform excels in simulation and molding applications, offering tools to test materials, designs, and processes virtually before going into production. This allows for a more streamlined approach to manufacturing, reducing errors and saving costs.

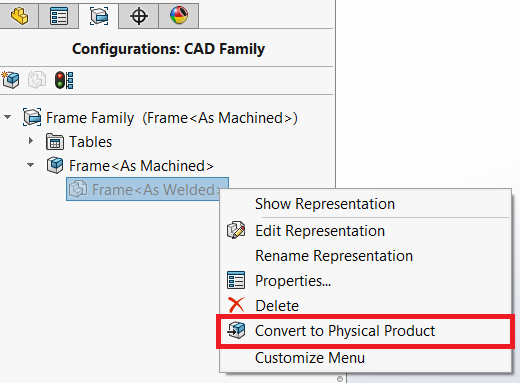

The Power of PDM & PLM

xApps also support PLM capabilities, helping you manage product data throughout the lifecycle. This is especially useful for managing PDM and PLM systems, ensuring that all product information is up-to-date and easily accessible to all team members.

How Can xApps Improve Your Sheetmetal and Mold Design?

For anyone working with sheet metal, the 3DEXPERIENCE platform brings improved sheet metal design capabilities. These apps offer precise control over sheet metal features such as bends, cuts, and folds, making them an essential tool for anyone dealing with enclosures or complex mold designs.

How Do xApps Enhance Geometry Creation and Modification?

Creating and modifying complex geometry is a critical aspect of the design process, and these apps offer intuitive tools to streamline this task. Whether you’re designing intricate sheet metal components or organic forms for molding, apps like xDesign and xShape provide users with flexible modeling options. These tools enable designers to manipulate geometry in real-time, making adjustments with ease and precision. With associative parametric design capabilities, any changes to the geometry automatically update across the model, reducing errors and saving time in revisions.

By leveraging these geometry tools within your SOLIDWORKS workflow, you can accelerate the design process while maintaining full control over the intricacies of your project.

Conclusion

By integrating 3DEXPERIENCE xApps into your SOLIDWORKS workflow, you unlock powerful tools for design, simulation, and collaboration, all accessible from any browser. Whether you’re working on sheet metal, moulding, or managing revisions, xApps streamline complex tasks and help boost productivity. With cloud-based functionality and intuitive interfaces, these apps empower designers and engineers to work smarter and more efficiently, making them an essential part of the modern CAD toolkit.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

3D Creator Streamlines Your Design Workflow

3D Creator Streamlines Your Design Workflow