In the age of environmental awareness, designing sustainable products has become a cornerstone of responsible engineering. From reducing waste to facilitating recycling and improving energy efficiency, the decisions made during the design phase significantly impact a product’s environmental footprint. SOLIDWORKS addresses these challenges with its robust Sustainability tools, enabling designers and engineers to integrate eco-conscious practices seamlessly into their workflows.

This article explores some of the stand-out features of the SOLIDWORKS Sustainability toolkit, demonstrating how they empower users to design with sustainability in mind and contribute to a greener future.

Why Does Sustainable Design Matter?

Sustainable design focuses on minimizing the negative environmental impact of products throughout their lifecycle—from material selection to end-of-life disposal. It prioritizes resource efficiency, waste reduction, energy conservation, and recyclability.

Key Principles of Sustainable Design

- Material Efficiency: Choosing eco-friendly, renewable, or recyclable materials.

- Energy Efficiency: Reducing energy usage during manufacturing and product operation.

- Waste Reduction: Designing products with minimal material waste during production.

- End-of-Life Planning: Facilitating recycling, reusing, or repurposing of products.

SOLIDWORKS Sustainability tools are built to help engineers and designers embed eco-conscious practices directly into their design workflows. They go beyond theoretical concepts, offering practical, data-driven features that turn sustainability goals into tangible design actions.

Overview of SOLIDWORKS Sustainability Tools

SOLIDWORKS offers two primary tools for sustainability analysis:

- SustainabilityXpress: Integrated into the core SOLIDWORKS package, this tool provides a basic assessment of part documents, offering insights into the environmental impact of design choices.

- SOLIDWORKS Sustainability: Available in SOLIDWORKS Premium and Ultimate editions, this advanced tool extends functionality to include assemblies, configuration-specific analyses, and comprehensive reporting.

Get Actionable Insights

SOLIDWORKS Sustainability tools provide real-time feedback on critical environmental metrics, such as carbon footprint, energy consumption, air acidification, and water eutrophication. This data gives designers a clear picture of how their material choices, manufacturing processes, and design modifications affect the environment.

For example, a designer working on a product can immediately see how switching from virgin aluminum to recycled aluminum reduces the overall carbon footprint, helping them choose the most sustainable option without compromising performance.

Empower Informed Decision-Making

The integration of lifecycle assessment data ensures that you can consider the entire lifecycle of their product, from material sourcing and manufacturing to end-of-life disposal. This holistic view allows for smarter decisions that prioritize sustainability at every stage.

Tools like Material Comparison and Find Similar Materials make it easy to identify eco-friendly alternatives to traditional materials, enabling users to strike a balance between environmental responsibility and engineering requirements.

Stay Aligned with Established Design Principles

By focusing on material efficiency, recyclability, energy conservation, and durability, these tools directly support key principles of sustainable design. They encourage practices like lightweighting (using topology optimization) and modular design (facilitating disassembly and repair), which reduce resource consumption and extend product lifespan.

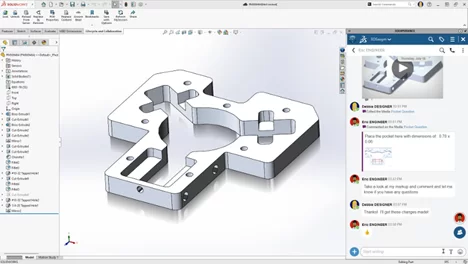

Experience Intuitive Usability and Integration

SOLIDWORKS Sustainability tools are integrated into your familiar SOLIDWORKS environment, making assessments an intuitive part of your design process rather than a separate, time-consuming step. This seamless integration ensures that even small design teams can incorporate sustainability into their workflows without requiring extensive training or additional software.

By providing immediate, meaningful feedback and enabling easy exploration of sustainable design alternatives, SOLIDWORKS Sustainability tools empower users to innovate while reducing environmental impacts, turning sustainable design from a lofty goal into an everyday reality.

Key Features of SOLIDWORKS Sustainability

Life Cycle Assessment (LCA) Integration

At the heart of SOLIDWORKS Sustainability lies its ability to perform lifecycle assessments. This feature evaluates the environmental impact of a product from raw material extraction to disposal, enabling designers to consider every phase of the product’s existence.

Key Metrics Assessed:

- Carbon Footprint: Total greenhouse gas emissions.

- Energy Consumption: Energy required during the product lifecycle.

- Air Acidification: Impact of emissions contributing to acid rain.

- Water Eutrophication: Nutrient pollution affecting water bodies.

The LCA feature provides real-time feedback, empowering users to adjust their designs to minimize negative environmental effects.

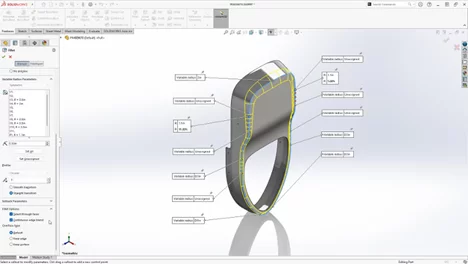

Material Selection and Analysis

Material choice is critical in determining a product’s sustainability. SOLIDWORKS Sustainability integrates a robust material database, allowing users to evaluate the environmental performance of different materials.

Features:

- Material Comparison: Assess the environmental impact of materials based on criteria like recyclability, carbon footprint, and energy usage.

- Find Similar Materials: Identify alternative materials with similar mechanical properties but lower environmental impact.

- Eco-Friendly Materials: Explore options for recycled or renewable materials.

Example: Switching from traditional plastic to a bioplastic alternative could significantly lower a product’s environmental footprint without sacrificing functionality.

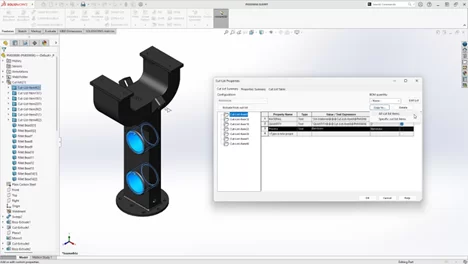

Environmental Impact Dashboard

The Environmental Impact Dashboard provides real-time visualization of sustainability metrics. This interactive interface allows users to monitor the effects of their design choices and adjust parameters as needed.

Benefits:

- View metrics like carbon footprint and energy usage at a glance.

- Experiment with design modifications to reduce environmental impact.

- Generate detailed reports for presentations or compliance documentation.

Example: A packaging engineer could use the dashboard to refine the shape of a container, reducing material waste while maintaining structural integrity.

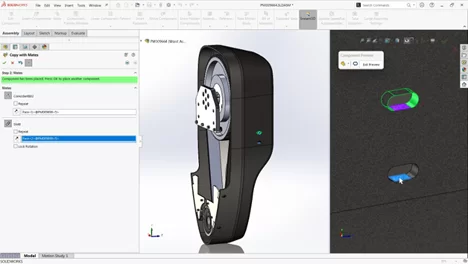

End-of-Life Analysis

Designing with the product’s end-of-life in mind is essential for sustainability. SOLIDWORKS Sustainability helps users consider disassembly, recycling, and reusability options.

Features:

- Assess recyclability of materials used.

- Simulate disassembly processes to identify areas for improvement.

- Design modular components for easier upgrades or repairs.

Example: A consumer electronics company can design a modular smartphone with replaceable components, ensuring longevity and easier recycling.

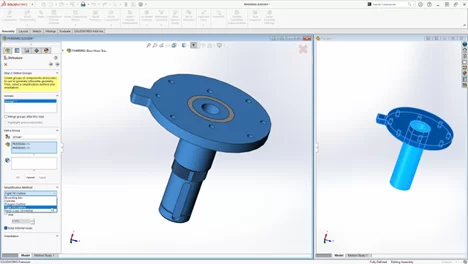

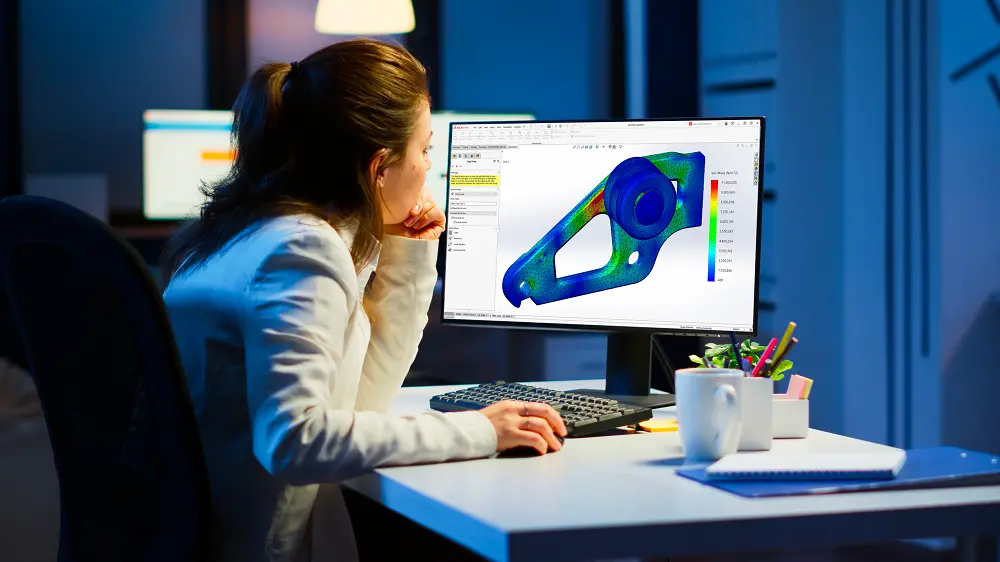

Simulation for Optimization

Efficient designs often require fewer resources and materials. SOLIDWORKS Simulation tools integrate seamlessly with Sustainability, helping you optimize your designs for minimal material usage and maximum durability.

Features:

- Topology Optimization: Reduce weight and material usage while maintaining strength.

- Stress Analysis: Ensure durability without overengineering components.

- Thermal and Flow Analysis: Optimize designs for energy efficiency in operation.

Example: An automotive designer could use topology optimization to create lightweight vehicle parts, improving fuel efficiency and reducing emissions.

Sustainability in a Circular Economy

Sustainability doesn’t end with the product’s lifecycle—it extends into a circular economy, where materials are continuously reused and recycled. SOLIDWORKS Sustainability supports circular design principles with tools that enable:

- Modular Design: Simplify repair and upgrades by creating replaceable modules.

- Disassembly Simulation: Ensure products can be disassembled efficiently for recycling.

- Lifecycle Evaluation: Optimize the entire lifecycle for minimal waste and energy use.

Example: Designing appliances with easily replaceable parts ensures a longer product lifespan and less electronic waste.

Business Benefits of Sustainable Design

Adopting sustainable practices isn’t just good for the environment—it’s also a sound business strategy. Companies that integrate sustainability into their designs can:

- Reduce Costs: Minimize material waste and energy usage during production.

- Enhance Brand Reputation: Appeal to eco-conscious consumers and stakeholders.

- Stay Ahead of Regulations: Meet or exceed environmental standards and certifications.

- Drive Innovation: Explore new materials, processes, and design methodologies.

Final Thoughts

Designing for a greener future and balancing technological innovation with environmental protection often feel like trying to hit moving targets. But, SOLIDWORKS Sustainability tools empower engineers and designers to tackle environmental challenges head-on, to more efficiently deliver products that align with eco-friendly values. By leveraging features like lifecycle assessments, material analysis, and topology optimization, you can create innovative designs that minimize waste, conserve resources, and facilitate recycling.

Ready to design for a greener future? Explore SOLIDWORKS Sustainability tools today and see how they can help you achieve your sustainability goals. Contact SolidXperts for expert guidance, training, and support to get started.

Together, let’s build a more sustainable tomorrow!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: