Description

$63,751,150,423.00

Revolutionize your manufacturing operations with flexible 3D printing and access to a wide range of reinforcement materials. Print parts that are stronger, harder, and durable enough to replace machined aluminium.

Description

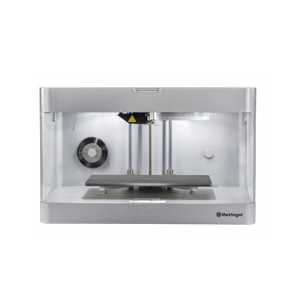

Markforged Mark Two

Desktop Composite 3D Printer

Starting at:

15990

*

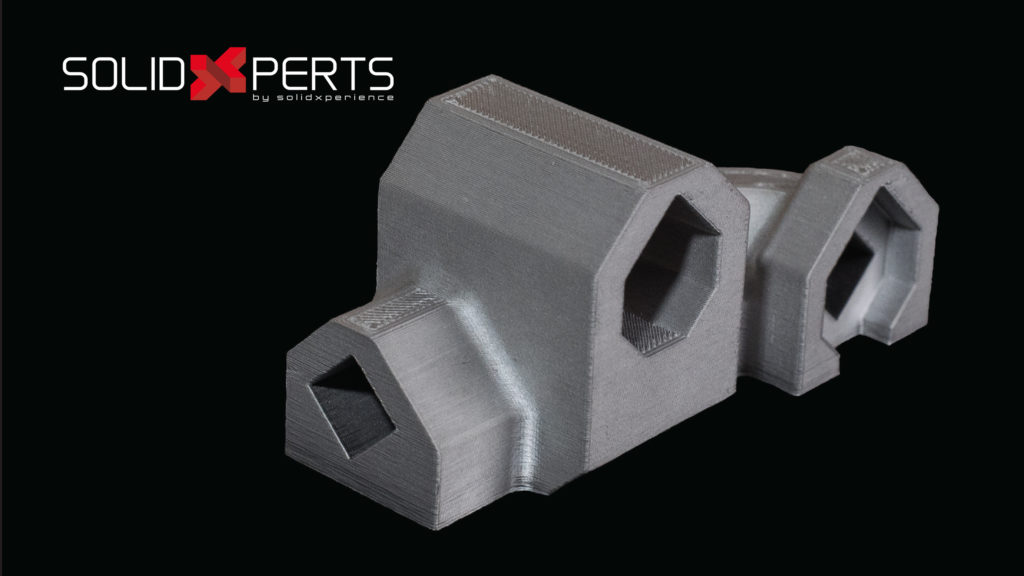

Revolutionize your manufacturing operations with flexible 3D printing and access to a wide range of reinforcement materials. With Markforged Mark Two you can print parts that are stronger, harder, and durable enough to replace machined aluminum.

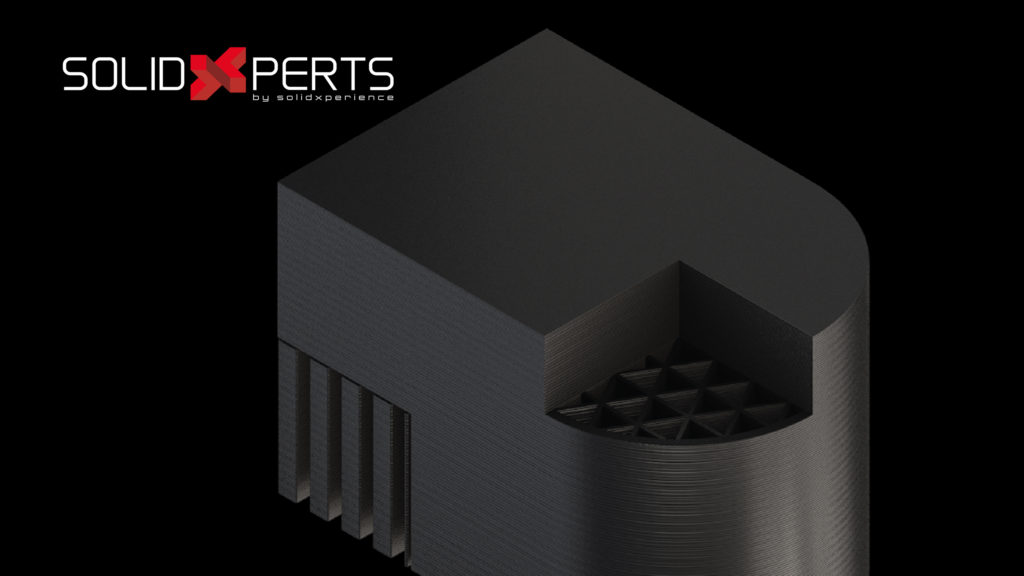

A truly flexible 3D printer that can produce aluminium-strength parts and fits on your desktop.

- With the Markforged Mark Two versatility is a given. Choose between Nylon and Onyx for your prints, and reinforce either base material with fiberglass, Kevlar, or carbon fiber.

- Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminium.

- Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber-filled nylon material.

What features do you get with Markforged Mark two?

- With a machine size of 584mm x 330mm x 355mm and a build volume of 320mm x 132mm x 154mm, the Mark Two produces your full 3D prints without sacrificing office space.

- A unibody aluminium chassis and precision-machined components deliver lights-out, workhorse reliability and repeatability over thousands of print hours.

- A hardened extrusion system enables the Mark Two to print Onyx — a micro carbon fiber filled nylon filament notorious for eroding traditional extrusion systems — reliably over thousands of print hours.

- The Mark Two is built to be easily operated and maintained, featuring easy-to-reach wear components like nozzles and feed tubes and a print bed that can be removed and replaced with 10μm repeatability.

Printer Specs

Additional resources

With its endless possibilities, our Xperts are here to help you find the right combination of solutions that will enhance your product by allowing you to innovate, develop, and design without limits.

Smooth TPU 95A

- Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand. Use Smooth TPU (Thermoplastic Polyurethane) for functional parts requiring elongation and flexibility. Print drive belts, bumpers, protective coverings, gaskets, and more with a smooth surface finish and high reliability. S-TPU is available in both black and white.

Onyx

- The go-to Markforged composite for printing accurate parts with a smooth surface finish, Onyx is a Nylon base reinforced with chopped carbon fiber that boasts high chemical and heat resistance. Onyx prints enjoy both a high-end finish and twice the strength of parts from other composite printers. Try printing with embedded carbon fiber reinforcements for aluminum strength parts.

Carbon Fiber CFF

- The literal and symbolic backbone of aluminum-strength, composite 3D printed parts, Carbon Fiber is the classic Markforged high-strength Continuous Fiber. Take advantage of the highest strength-to-weight ratio of the Markforged reinforcing fibers, 6x stronger and 18x stiffer than Onyx! Carbon Fiber reinforcement is commonly used to replace traditionally machined aluminum parts and fixtures.

Fiberglass

- As an entry-level continuous fiber material, Fiberglass is perfect for printing parts 10x stronger than ABS, or 2.5x stronger and 8x stiffer than Onyx alone. Print robust tools, jigs, and fixtures with Fiberglass inlays on the Onyx Pro and X5, and on the Mark Two and X7 for a more affordable, accessible carbon fiber alternative.

Fiberglass (HSHT)

- Of course, High Strength High Temperature Fiberglass (HSHT) is iconic for its aluminum strength and high heat tolerance. Onyx parts reinforced with HSHT are strong at both low and high temperatures and are 5x as strong and 7x as stiff as parts printed in pure Onyx. It’s best used for durable parts designed to operate in high temperatures.

Kevlar (Aramid Fiber)

- Tough Continuous Fiber for high-impact applications, Aramid Fiber is a Kevlar-based specialized continuous fiber known for its extreme energy absorption. Armor up with Kevlar reinforcement inlays that add strength and durability for parts as stiff as fiberglass and much more ductile. When laid into Onyx or another composite base material, achieve impact-resistant pieces that are nearly immune to catastrophic failure!

Precise PLA

- Precise PLA is an easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

Customer stories

Ready to

unlock your potential?

Please fill the form and we will contact you soon!

Additional information

| Part Caracteristics | Fiber Reinforced, Heat Resistant, Strength |

|---|---|

| Process | Production |

| Brand | Markforged |