Description

$63,751,150,423.00

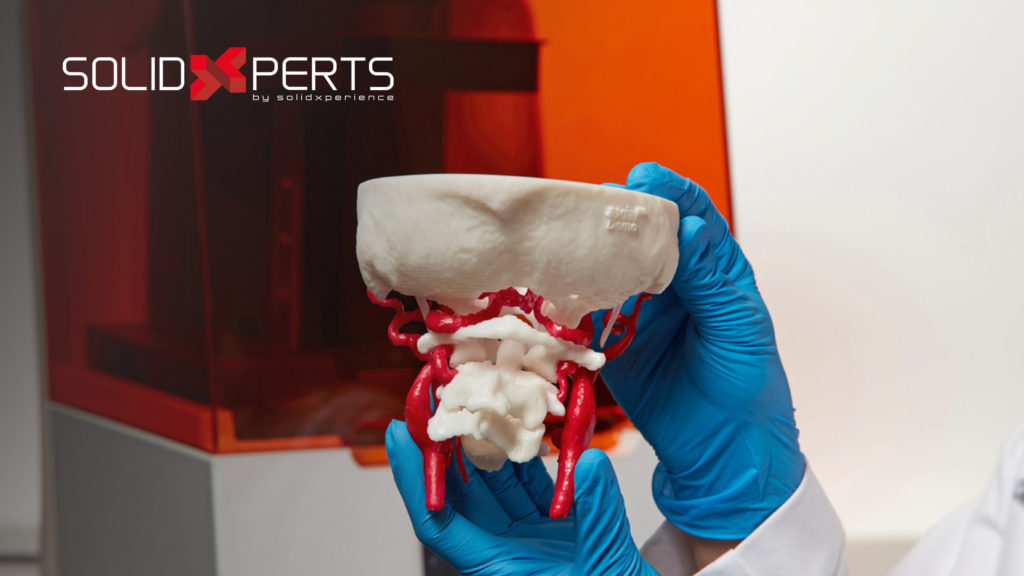

Leverage the power of Continuous Fiber Reinforcement for printed parts that are 10x stronger than ABS at a competitive price point.

Description

Markforged Onyx Pro

Desktop Composite 3D Printer

Starting at:

8990

*

Leverage the power of Continuous Fiber Reinforcement for printed parts that are 10x stronger than ABS at a competitive price point.

The workhorse professional 3D printer for Continuous Fiberglass reinforced parts.

- Print extremely durable, Continuous Fiberglass reinforced parts that are 10x stronger than plastic and are even capable of replacing some of your existing machined aluminum parts.

- Compact desktop 3D printer, that’s easy to use and easy to install at your office or studio.

- With Markforged Onyx Pro, Design your part, upload it into Eiger browser-based software, slice the part in Onyx, reinforce the part with Continuous Fiberglass, and hit print. It’s that simple.

What features do you get with Markforged Onyx Pro?

Printer Specs

Smooth TPU 95A 800 cc

- Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand. Use Smooth TPU (Thermoplastic Polyurethane) for functional parts requiring elongation and flexibility. Print drive belts, bumpers, protective coverings, gaskets, and more with a smooth surface finish and high reliability. S-TPU is available in both black and white.

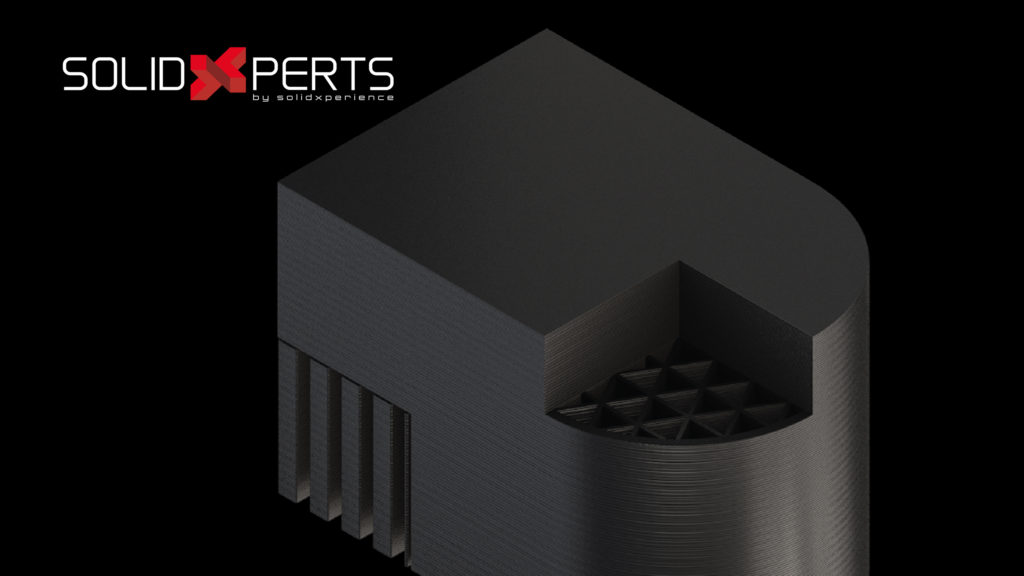

Onyx

- The go-to Markforged composite for printing accurate parts with a smooth surface finish, Onyx is a Nylon base reinforced with chopped carbon fiber that boasts high chemical and heat resistance. Onyx prints enjoy both a high-end finish and twice the strength of parts from other composite printers. Try printing with embedded carbon fiber reinforcements for aluminum strength parts.

Fiberglass

- As an entry-level continuous fiber material, Fiberglass is perfect for printing parts 10x stronger than ABS, or 2.5x stronger and 8x stiffer than Onyx alone. Print robust tools, jigs, and fixtures with Fiberglass inlays on the Onyx Pro and X5, and on the Mark Two and X7 for a more affordable, accessible carbon fiber alternative.

Precise PLA 600cc Spool

- Precise PLA is an easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

Additional information

| Brand | Markforged |

|---|---|

| 3D Printer Caracteristics | FDM |

| Materials | Onyx |

| Part Caracteristics | Electrostatic, Fiber Reinforced, Heat Resistant, Strength |