ASSEMBLIES

Optimization of lightweight / resolved :

Lightweight supports part mass and similar properties.

Auto repair of mate references

Improved assembly cut feature

Highlighting for overwritten BOM cells

Specify the default BOM part number (as either Document or Configuration name)

Improved STEP export

Preview of Replace Component with instance(s) to replace controls

Color option for Explode Lines

Specify affected configuration(s) for skipped instances in patterns.

Ability to suppress magnet mates & related connection points

Override computed mass or cg values with Design Table entries

Assembly feature propagation blocked from affecting Toolbox parts

Assembly patterns with skipped instances are easier to configure.

Replace component improvement, better options for instances, and more.

COMPOSER

View Collections capability

Updated import file format support

Support of Pro/E, CREO & STEP meta properties

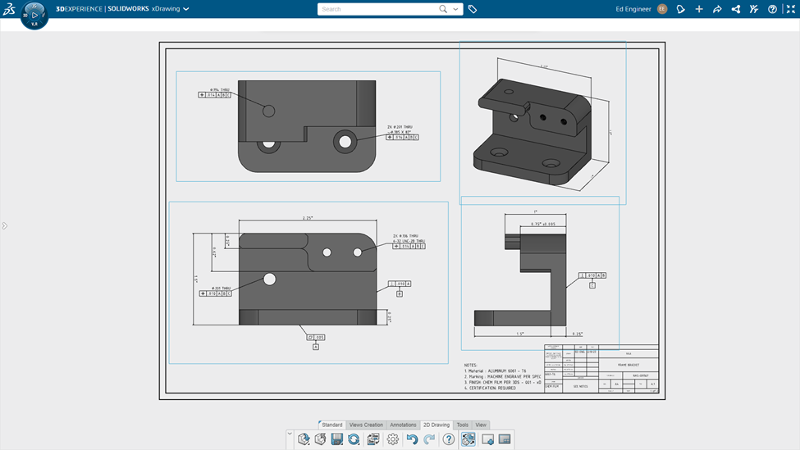

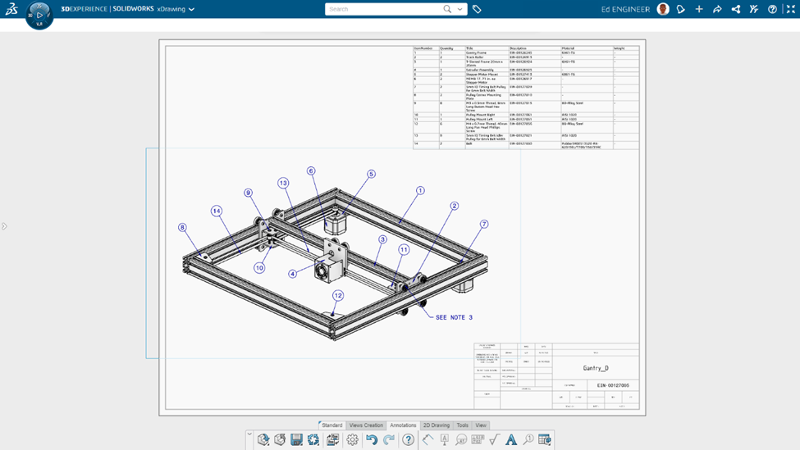

DRAWINGS

Component Name display choices made in part or assembly feature tree are reflected in the Drawing view pallet.

Detached Drawings are fully discontinued and replaced with Detailing Mode

Detail drawings of assembly components can be opened directly from the assembly drawing without opening respective geometry files.

RMB graphics area, BOM cell, or drawing view tree.

Not fully supported for Detailing Mode.

BOM table overrides can now have a specific highlight color. (default Sys Opt is black)

RMB selection is provided to restore to original values per cell, row, column, or the entire table.

Highlight color only shows when the table is selected. (not for print and so on)

Quantity indicators now allowed for Auto Balloons as well as manual balloons.

BOM tables can now be filtered like a spreadsheet, and the auto balloons update to match.

Do not combine filtering with the hiding of columns or rows.

Transparent component support for HLR / HLV views improved to match with ISO standard 128-2020.

Check box option in view PM or in Document Properties.

Hole Tables now support punches and slots in addition to holes (a top 10 ER).

GeoTol symbols can be limited to the current drawing standard.

Vector translation modifier now supported in GeoTol frames.

Dynamic Profile Tolerance supported per ASME Y14.5-2018

EDRAWINGS

Assembly display and publish improvement

Model Configuration support for eDrawings mobile apps

Publish support for Display States in eDrawings

Display Style improvements

File type version enhancement

Multi-language support for eDrawings to web HTML

Inch fractional measurement units

ELECTRICAL

Support for hybrid drawings – schematics & tables combined on 1 sheet

Component dynamic connection label annotations supported in schematics

Ability to set 3D part mass props from Electrical Schematic properties (per spec sheet)

Improved condition icons for 3D electrical components (inserted, connected, and so on)

Open ended wire support in schematic. (for pigtails or wire on install connections)

Schematic sheets support more image types. (tiff, png, jpg)

Deleting Component can force deletion of related symbols

Reset for Dismissed Messages

Excel Automation Improvement

Origin -> Destination specification

FLOW

Mesh Boolean Operation – allows meshes to create even when base geometry is imperfect

Turbidity Factor – for solar radiation effects, accounts for polluted or storm-filled atmosphere

Reduces heat effects in some cities versus open desert

Plot Cropping – (cut, mesh, surface) restrict the display to a particular material or fluid domain

Tangential & Radial Velocity effects for Fan Curves – property allows a more thorough definition of fan performance

Heat conductance on porous media as dependent on specific mass flow – increases accuracy for compressible fluid and gas flows.

Project Tree Sorting – alphabetically or chronologically

Transient Explorer export options – export results by time range, or for the active time moment

Transient Explorer custom parameters – for better visualization

New Study Goals –

Total Energy Balance

Volumetric Heat Generation Rate

Radial & Axial Velocities

Flux Plots with total energy balance display

Performance – Mesher and Solver operations are now faster due to improved memory use management

IMPORT/EXPORT

Large assembly export supports individual STEP file generation

Textured *.obj file import is improved

INSPECTION

AddIn – Balloon Sequence configurability

With multi-sheet options

Addin – Balloon Drawing Sheets Separately

Addin – Export sheets as separate PDF files

Addin – Export reports as separate Excel files

Addin – Inspection Manager with Characteristic tree view

Standalone – Autoballoons for PDF drawings

Standalone – Manual Extract replacement for OCR (better results)

Machine Learning support for 2D PDF

Sheet selection mode for multi-sheet drawings

Export Reports to individual Excel files

Balloon Sequencing

INSTALLATION & SNL

Flow Simulation HVAC and Electronics Cooling modules can now be independent AddIns and the SNL licenses loaded or unloaded as needed rather than always being reserved with each use of Flow Simulation.

Term licenses now show pending expiration in the SNL manager and can be renewed or reactivated by individual serial numbers.

All products will now have a term license option.

MANAGE

Automatic update of mapped linked records

New From option for data fields

BOM field comparison (linked vs primary)

Variable Driven BOM Qty support

Cancelled Tasks reflect properly in capacity planning

Task Board Display

MBD

View control for all dimension types, not just DimXpert annotations

Hole Tables support multiple views

Dimension Extension Line

Datum Feature editing

Wedge as geometric & annotation feature

Support for ISO Tolerance modifiers

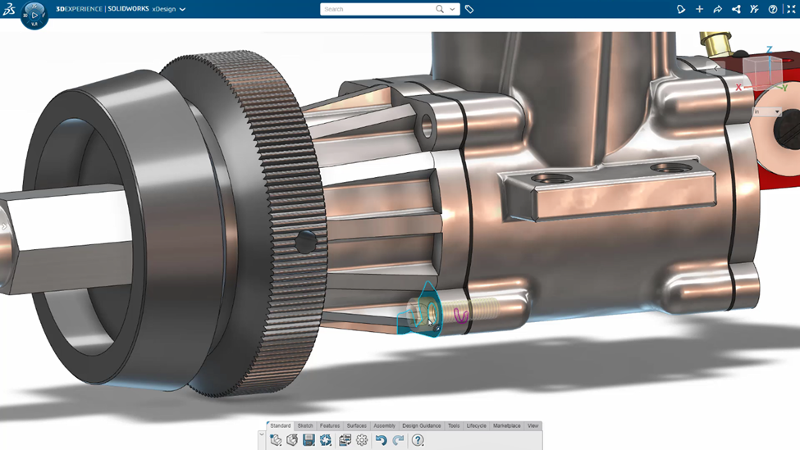

PART MODELING

Support of Move/Copy Body translation or rotation values in Equations and Design Tables

Defeature now supports creating derived configurations for parts as well as assemblies.

Dimension support in Move/Copy Body

Allowance of Library Feature Errors – click [Yes] to accept the feature errors, and then correct them after the insertion in the current part.

Coordinate Systems are now valid for selection in more commands – such as, 3D sketch operations, 2D sketch dimensions, mirror, and during select other

Single stroke font support in Wrap Feature sketches (Scribe wrap type)

OLFSimpleSans – is installed by SOLIDWORKS

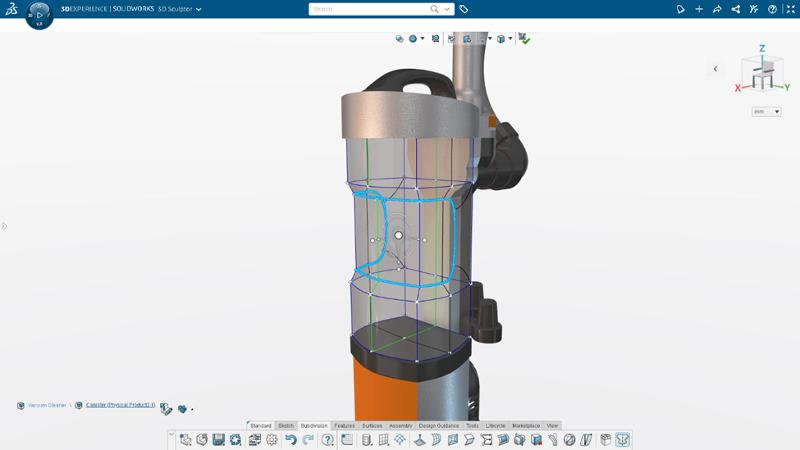

Hybrid Mesh-BREP modeling improvements

Extended feature support

Section View creation through Axis

Euler method rotation is now allowed for Move/Copy Body, and it can be set per configuration.

Move/Copy Body translations can also be set per part configuration now.

Global variables or equations can now be used to drive the Move/Copy Body values.

PDM

HTML customization for Notification templates

File Version Upgrade Tool – supports overwriting latest version

Streamlined UI for check-in/out

New options to manage Deleted Users

Transition Actions configurable by user account and properties thereof

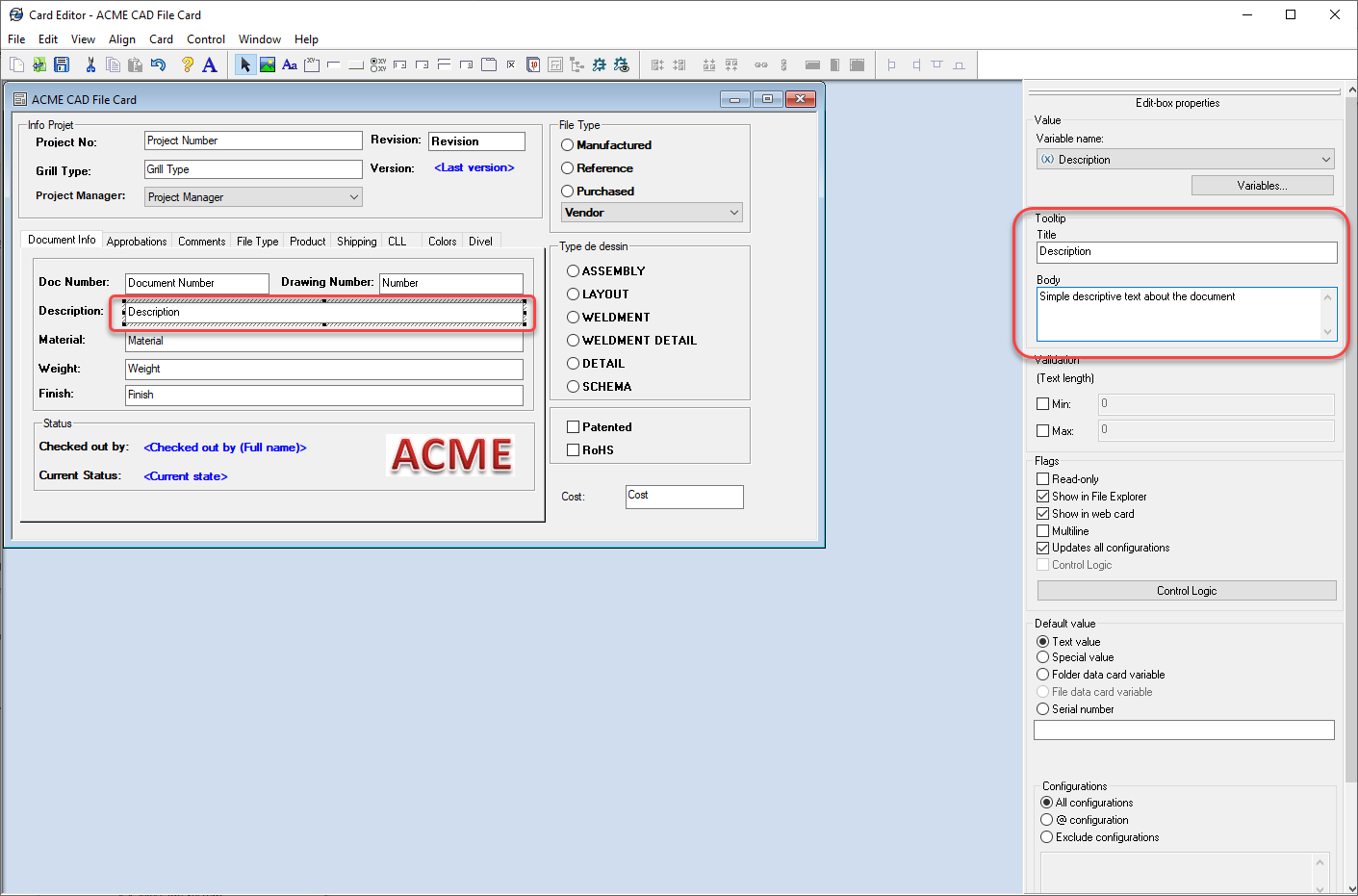

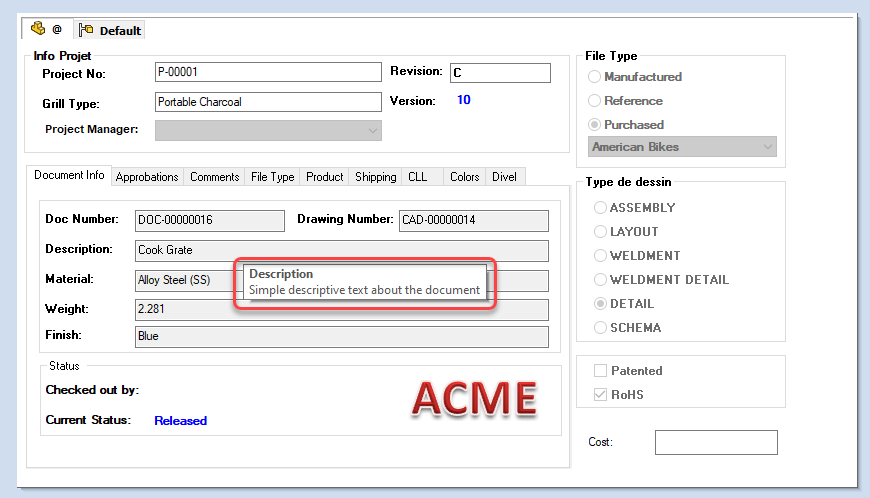

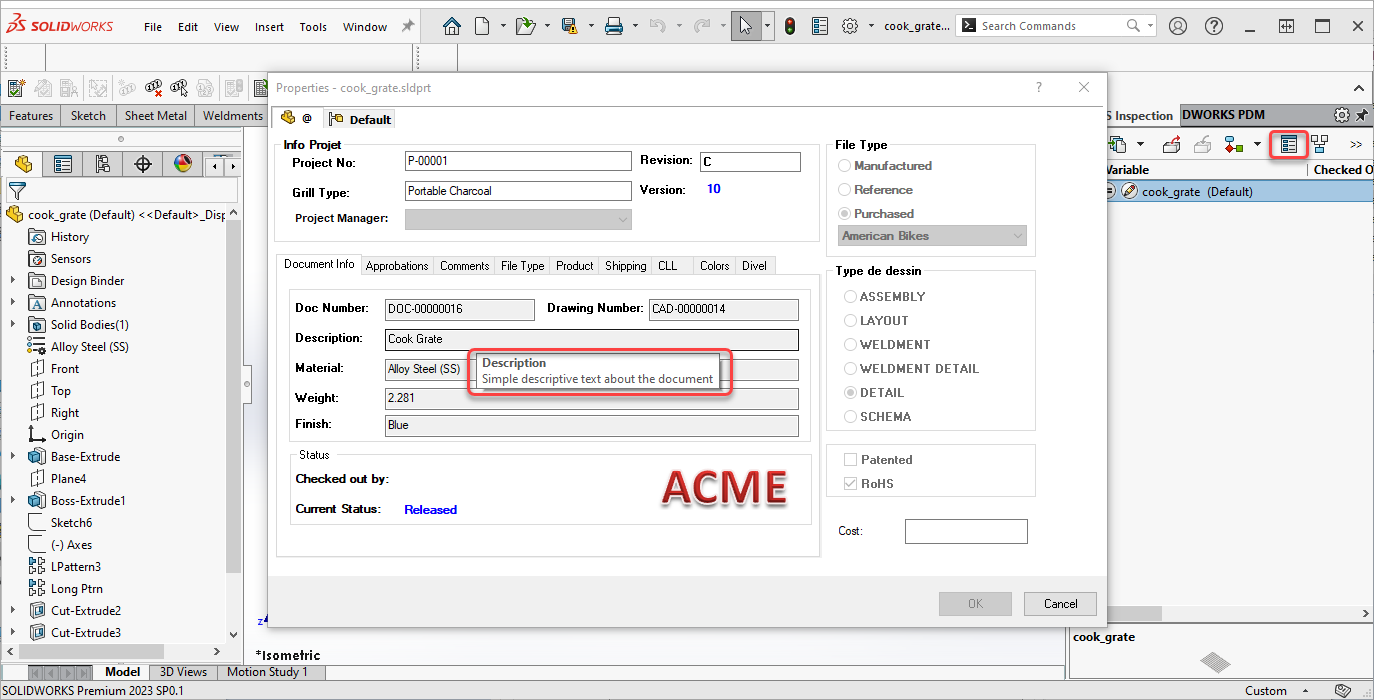

Tooltips can be added to Data Card fields

Improved Data Card controls

Copy & Paste display text to variable fields

Buttons can have user-lookup data (names, AD fields, and so on)

Better image file support. (jpg, png)

Logging of File Retrieval Operations ([x]Get log property at PDM Pro server)

Display source Groups for Inherited User Permissions

All data transfers encrypted to/from the server

STEP export task enhanced for 242, or shattered assembly components.

eDrawing files in the vault support thumbnail previews in the explorer panel.

Autologin option for vault Admin. (setting in the admin tool at a local machine)

Archive Server & Database Server improved in higher latency environments (Azure, AWS)

Private State folder visibility option for non-Admin users.

PERFORMANCE

Level of Detail system option to improve graphics changes (zoom, pan, rotate) for most view types.

Faster save operations for large assemblies with some amount of unchanged components.

PDM is faster and more efficient in high-latency networks.

PDM file version upgrade tool operates faster.

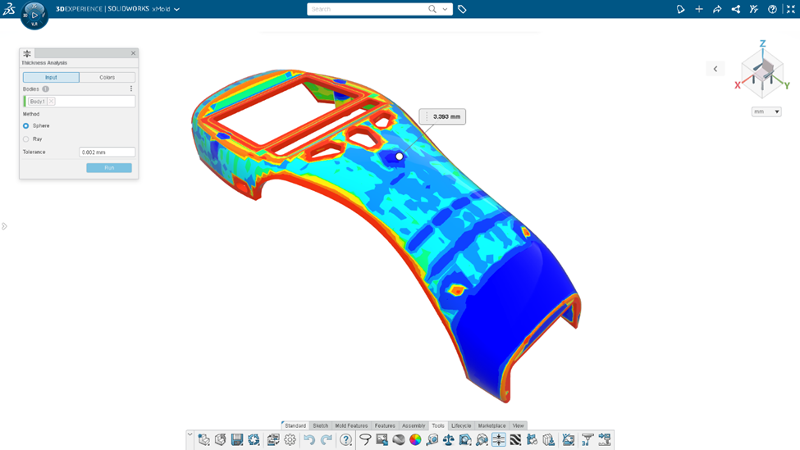

PLASTICS

Material Database & Material Grade additions

Material Database UI improvement

Report enhancements

ROUTING

Improved electrical flattening and manufacturing drawings

With better connector tables.

Multi-wire circuit splice support.

Design Library auto-style clips added.

Routing Library Manager performance and usability improvements.

Harness diameter & length are show in an electrical route property manager.

Accommodates and displays unused cores.

Auto Route improvement for discrete wires

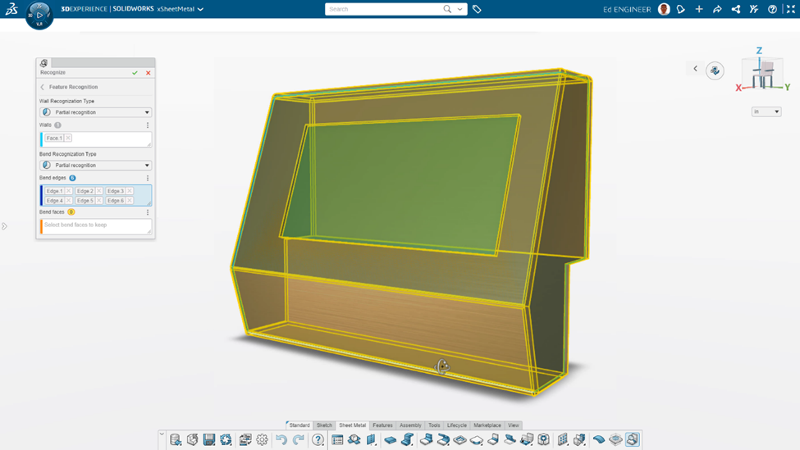

SHEET METAL

Deviation sensor

You can create a sensor to alert that the sheet metal exceeds a bounding box size. (max length, width, area, blank area)

Symmetrical Thickness

Specifies material to be applied symmetrically from the base flange sketch.

Gauge Values in Cut List properties (and drawing notes)

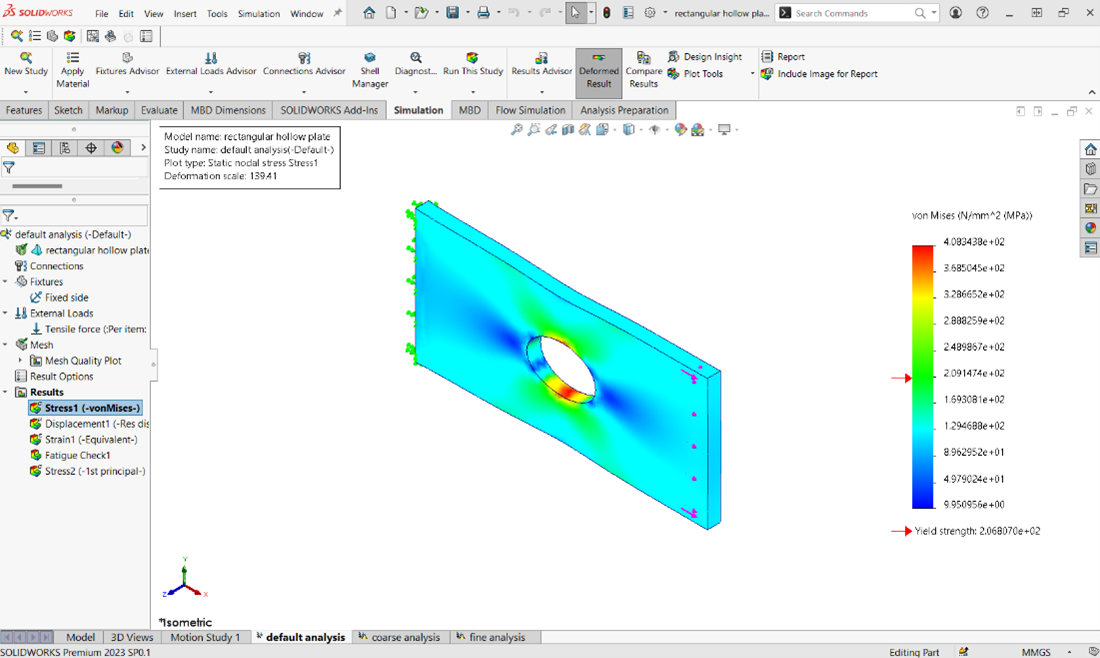

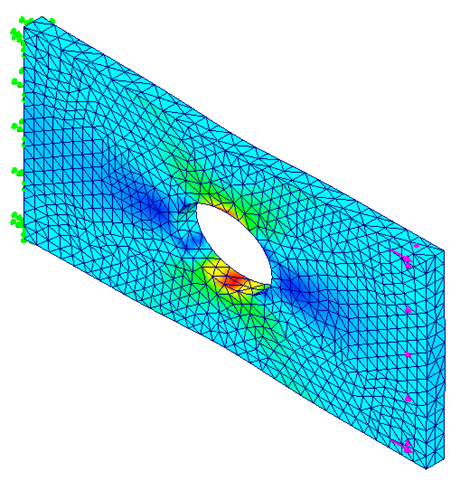

SIMULATION

Improved surface to surface bonding interactions (allowed for non-contacting faces)

For ignoring set screws, pins, etc.

Diagnostic Tools

Linkage Rod Connector

Penalty Stiffness Control for Contact (up to 50% solve)

Solver improvements

Underconstrained Body management (Simulation Professional & Premium)

SKETCHING

Elipses now have options to create construction lines across the axes.

SOLIDWORKS CAM

Barrel Tool Support

Improved Leadin & Leadout Calcuation for contour milling

Lines Only Option for VoluMill Toolpath

Tolerance Based Machining improvements

STABILITY

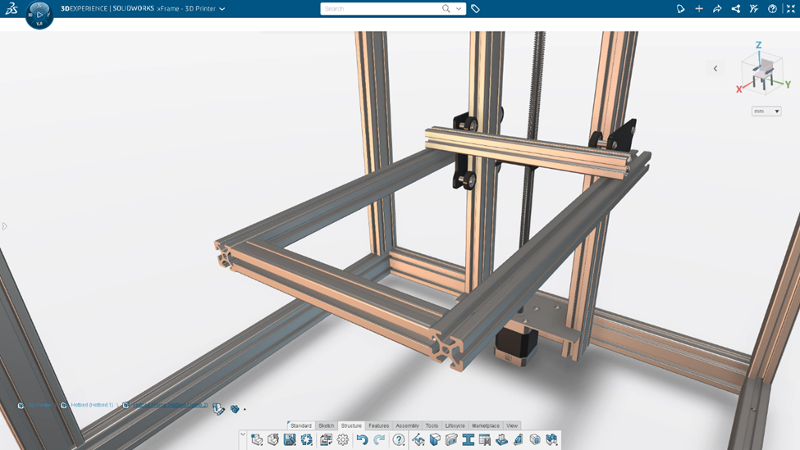

90% reduction in customer reported crash SPRs.STRUCTURE SYSTEMS

Corner Trims of similar corners by Group, with Connection Plates by Group

Configuration specific weldment member sizes

Alignment of Custom Properties Attributes (for matching with 3DEXPERIENCE attribute types)

USER INTERFACE

Comments in SOLIDWORKS files now have additional color and formatting options.

Comments can be set to Show At Start when files are opened.

Improved Restore Default Settings options and behavior.

Improved behavior of Copy Options Wizard.

VISUALIZE

Color Picker tool improvements

DSPBR Materials Support

Import Options (grouping) are easier for SOLIDWORKS files

Stellar Physically Correct illumination render

PhotoView 360 to be retired at 2023 sp5.