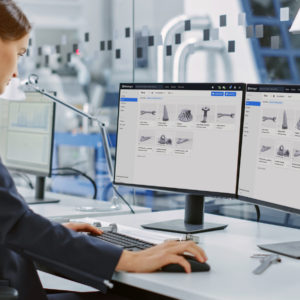

Option 1: Upgrade to 3DEXPERIENCE SOLIDWORKS

Option 1: Upgrade to 3DEXPERIENCE SOLIDWORKS

Seamlessly transition from SOLIDWORKS Desktop to 3DEXPERIENCE SOLIDWORKS, and experience a new dimension of design and collaboration. With secure cloud data management, increased collaboration capabilities, and reduced IT administration, 3DEXPERIENCE SOLIDWORKS empowers your team to work smarter and faster.

Option 2: Upgrade to SOLIDWORKS TERM w/Cloud Services

Option 2: Upgrade to SOLIDWORKS TERM w/Cloud Services

Opt for SOLIDWORKS TERM with Cloud Services, a flexible and convenient option that combines the power of SOLIDWORKS with the benefits of cloud-based solutions. Say goodbye to traditional licensing hassles and welcome easy deployment and automatic updates for a seamless design experience.

Promotion Perks:

- This promotion covers both Standalone and Network licenses (SNL), making it suitable for businesses of all sizes.

- Take advantage of the promotion price and add as many new licenses (3DEXPERIENCE SOLIDWORKS or SOLIDWORKS TERM w/Cloud Services) as you need on the same Purchase Order, with no limit on extra seats.

- Enjoy the promotion discount for 3 years, whether purchased annually or upfront.

- Even after the promotion period, you’ll continue to benefit with a 25% discount on successive years.